What Is the Purpose of a Capacitor? Data-Driven Insights

A capacitor plays a vital role in electronics by storing and releasing electrical energy. This ability makes it indispensable for energy storage, signal filtering, and voltage stabilization. For example, capacitors store energy in an electric field, which can be released instantly in applications like flash photography. They also filter noise in power supply circuits, ensuring stable voltage for sensitive components. In digital circuits, capacitors prevent interference between different sections, maintaining smooth operation.

The global demand for capacitors reflects their importance. By 2024, the market size is projected to reach $607.7 billion, with 10 billion units consumed worldwide. As electronics evolve, selecting the right capacitor for your application becomes increasingly critical. Whether you’re designing renewable energy systems or automotive electronics, understanding what is the purpose of a capacitor ensures optimal performance.

Key Takeaways

Capacitors hold and release electrical energy. They are important for storing energy, filtering signals, and keeping voltage steady in circuits.

There are different types of capacitors like ceramic, electrolytic, film, and supercapacitors. Each type has special uses and benefits, so pick the right one for your needs.

Capacitors improve circuits by keeping power steady, stopping interference, and helping with accurate timing in devices like clocks.

In renewable energy, capacitors keep power stable and help connect to the grid. They are key for clean energy systems.

Always check datasheets for details like capacitance and voltage limits. This helps you choose the best capacitor for your project.

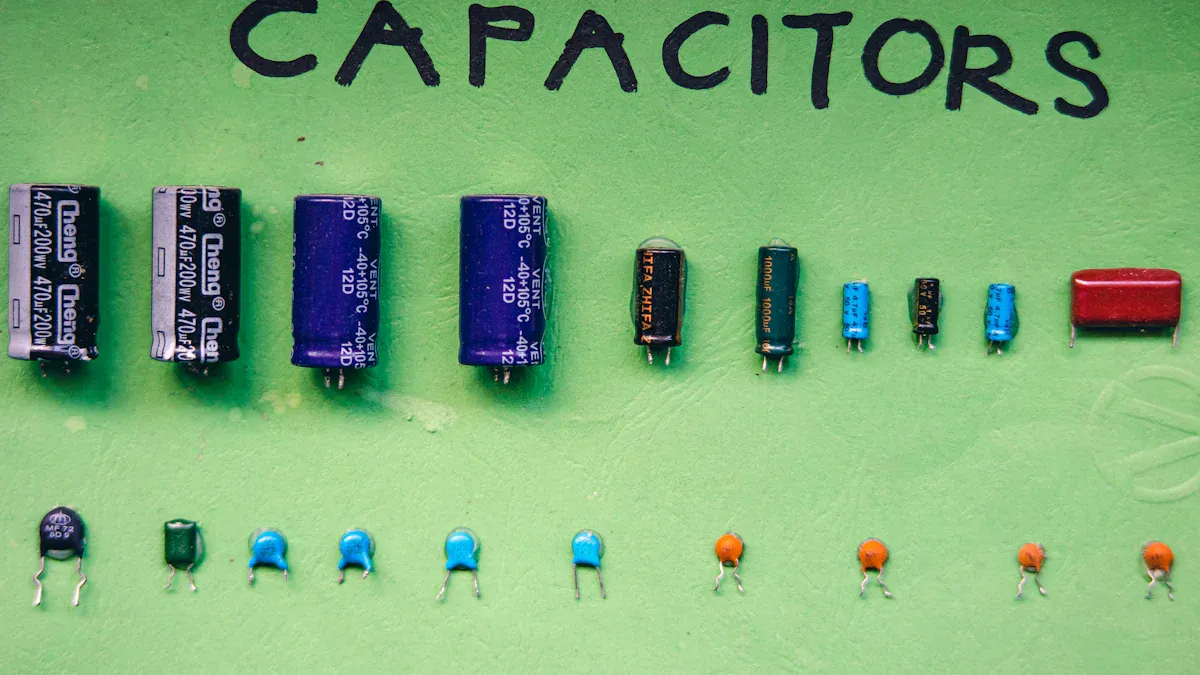

Overview of Capacitor Types

Capacitors come in various types, each designed for specific applications. Understanding these types helps you choose the right one for your needs. Below, we explore three common capacitor types: ceramic capacitors, electrolytic capacitors, and film capacitors.

Ceramic Capacitors

Ceramic capacitors are among the most widely used in electronics. These capacitors use ceramic as the dielectric material, making them suitable for high-frequency applications. Their non-polar nature allows you to place them in any orientation on a circuit board. The multi-layer ceramic capacitor (MLCC) is a popular variant, offering high capacitance in a compact size. MLCCs are ideal for decoupling power supplies and filtering noise in circuits.

Ceramic capacitors excel in handling high current pulse loads and strong transients. Their low equivalent series resistance (ESR) makes them reliable for power systems. Unlike some other types, ceramic capacitors do not pose a risk of explosion, ensuring safety in critical applications. You’ll often find them in coupling, decoupling, and impedance matching tasks.

Electrolytic Capacitors

Electrolytic capacitors, particularly the aluminum electrolytic capacitor, are known for their high capacitance values. These capacitors are polar, meaning you must connect them correctly to avoid damage. They are commonly used in power supplies to smooth out rectified voltage and store energy for later use.

Applications include buffering in DC power supplies, motor starters, and energy storage for flash units. Their ability to handle large capacitance makes them indispensable in circuits requiring bulk energy storage. However, they have a shorter lifespan compared to other types, especially in high-temperature environments.

Film Capacitors

Film capacitors use materials like polyester or polypropylene as the dielectric. These capacitors are highly durable and reliable, often lasting two to three times longer than aluminum electrolytic capacitors. Their self-healing properties allow them to recover from breakdowns, enhancing their lifespan.

Polypropylene capacitors, a subtype of film capacitors, perform exceptionally well in high-frequency and high-temperature applications. They are ideal for AC power systems and circuits requiring high surge currents. Film capacitors also offer low ESR and ESL, ensuring minimal energy loss during operation. You’ll find them in applications like filters, snubbers, and energy storage.

Tantalum Capacitors

Tantalum capacitors are a type of electrolytic capacitor that uses tantalum as the primary material for its electrodes. These capacitors are known for their high reliability and stability, making them a popular choice in critical applications. You’ll often find them in medical devices, aerospace systems, and high-performance electronics where consistent performance is essential.

One of the key advantages of tantalum capacitors is their ability to maintain stable capacitance over time. Unlike ceramic capacitors, which experience aging and a gradual decrease in capacitance, tantalum capacitors remain unaffected by time. However, they are polarized, meaning you must connect them correctly to avoid damage. Their linear temperature response ensures predictable performance across a wide range of operating conditions.

Here’s a quick comparison between tantalum capacitors and ceramic capacitors:

Aspect | Tantalum Capacitors | Ceramic Capacitors |

|---|---|---|

Aging | Do not age; stable capacitance | Experience aging; capacitance decreases over time |

Polarization | Polarized; requires correct terminal connection | Non-polarized; can connect to AC sources |

Temperature Response | Linear capacitance change | Non-linear response; can be designed for linearity |

Voltage Response | Consistent stability with applied voltage | Capacitance changes with voltage; can lose significant capacitance at rated voltage |

Tantalum capacitors are particularly useful in applications requiring compact size and high capacitance. For example, a tantalum electrolytic capacitor is often used in power supply circuits to stabilize voltage and filter noise. Its small size and high energy density make it ideal for portable devices like smartphones and tablets. However, you should avoid using them in circuits with high ripple currents, as they are sensitive to overvoltage and overheating.

Supercapacitors

Supercapacitors, also known as ultracapacitors, are a unique type of capacitor that bridges the gap between traditional capacitors and batteries. They store energy using an electrical double layer and redox pseudo-capacitance, allowing them to achieve much higher capacitance values than conventional capacitors. You’ll find supercapacitors in applications requiring rapid charge and discharge cycles, such as regenerative braking systems in electric vehicles and backup power supplies.

One of the standout features of supercapacitors is their exceptional cycle life. They can endure over 100,000 charge-discharge cycles, far surpassing the lifespan of traditional capacitors. Additionally, their ability to deliver a charge in as little as 10 seconds makes them ideal for applications requiring quick bursts of energy. Supercapacitors also operate across a wider temperature range, ensuring reliability in extreme conditions.

Here’s how supercapacitors compare to traditional capacitors:

Feature | Supercapacitors | Traditional Capacitors |

|---|---|---|

Energy Storage Mechanism | Uses electrical double layer and redox pseudo-capacitance | Uses dielectric material |

Charge/Discharge Speed | Can deliver charge in as fast as 10 seconds | Slower charge/discharge rates |

Cycle Life | Can last over 100,000 cycles, up to 1 million cycles | Typically fewer cycles |

Capacity | Higher capacity due to larger surface area of electrodes | Lower capacity |

Operating Temperature Range | Wider operating temperature range | Limited temperature range |

Supercapacitors excel in renewable energy systems, where they store energy from solar panels or wind turbines for later use. Their high capacity and rapid response make them indispensable in modern energy storage solutions. However, they are not suitable for long-term energy storage due to their relatively high self-discharge rate.

Comparison of Capacitor Types

Key Characteristics

Capacitance Range

When comparing capacitance ranges, you should consider several factors that influence performance:

Equivalent series resistance (ESR) affects energy loss and heat generation.

Physical size and cost often correlate with capacitance and voltage ratings.

Dielectric strength determines how much voltage a capacitor can handle before breakdown.

Temperature limits ensure operational safety in extreme conditions.

DC biasing can alter capacitance values under real-world conditions.

Ceramic capacitors typically offer lower capacitance values, making them ideal for high-frequency applications. Electrolytic capacitors provide higher capacitance, suitable for energy storage. Film capacitors balance capacitance and stability, while supercapacitors excel in ultra-high capacitance for rapid charge-discharge cycles.

Voltage Rating

Voltage ratings vary significantly among capacitor types. Here’s a quick comparison:

Capacitor Type | Voltage Rating Range | Key Characteristics |

|---|---|---|

Ceramic Capacitors | A few volts to several hundred volts | High voltage ratings, suitable for diverse applications. |

Electrolytic Capacitors | 6.3V to 500V (some higher) | Higher capacitance, polarized, requires correct polarity. |

Film Capacitors | 50V to several thousand volts | Excellent stability, low ESR, high reliability. |

You should match the voltage rating to your application to avoid capacitor failure.

Physical Size

The physical size of a capacitor impacts its usability in compact electronic devices. Miniaturization techniques, such as using thin dielectric materials, improve volumetric efficiency. Ceramic capacitors are small and fit well in compact designs. Electrolytic capacitors, while larger, offer high capacity. Film capacitors strike a balance between size and performance, while supercapacitors are bulkier due to their high energy density.

Strengths and Weaknesses

Ceramic Capacitors

Advantages:

Low ESR minimizes power loss in high-frequency applications.

High-quality factor (Q) ensures efficiency.

Stable capacitance across temperature ranges.

Disadvantages:

Aging reduces capacitance over time.

Capacitance decreases under DC bias.

Electrolytic Capacitors

Advantages:

High capacity for energy storage.

Cost-effective for bulk capacitance needs.

Disadvantages:

High temperatures cause electrolyte evaporation, reducing lifespan.

Sensitive to overvoltage and ripple currents, leading to potential failure.

Film Capacitors

Advantages:

Long lifespan and self-healing properties.

Disadvantages:

Larger size compared to ceramic capacitors.

Higher cost for specialized applications.

Tantalum Capacitors

Advantages:

Stable capacitance over time.

Compact size with high energy density.

Disadvantages:

Sensitive to overvoltage, risking thermal runaway.

Supercapacitors

Advantages:

Exceptional cycle life, lasting over 100,000 cycles.

Disadvantages:

Lower energy density compared to batteries.

High self-discharge rate limits long-term energy storage.

Tip: Always evaluate the advantages and disadvantages of each capacitor type to ensure optimal performance in your electronic applications.

Specific Applications of Capacitors

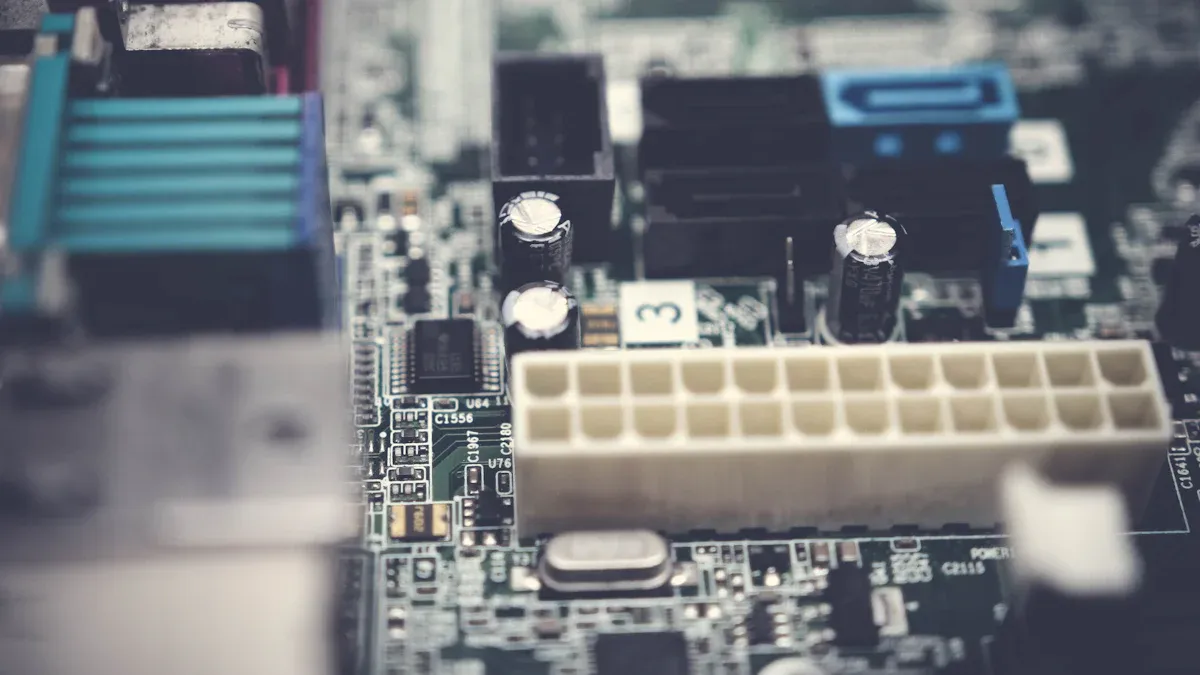

Capacitors play a crucial role in various electronic applications. Their ability to store and release energy makes them indispensable in power supply filtering, signal coupling and decoupling, and energy storage.

Power Supply Filtering

Capacitors ensure stable operation in power supply circuits. They reduce noise and improve the reliability of the overall circuit. In power supplies, reservoir capacitors smooth out the rectified voltage from power lines. This process eliminates fluctuations, providing a steady DC output.

You’ll often find capacitors in low-pass, high-pass, band-pass, and band-reject filters. These filters manage voltage fluctuations and ensure consistent performance. Capacitors must also handle discharge and charging currents effectively. For this reason, selecting a capacitor with a sufficient ripple current rating is essential.

Tip: Use high-quality capacitors in power supply filtering to enhance circuit stability and reduce noise.

Signal Coupling and Decoupling

Capacitors are essential for separating AC and DC signals in electronic circuits. Coupling capacitors allow AC signals to pass while blocking DC. Decoupling capacitors, on the other hand, block AC signals and allow DC to pass.

In practical applications, coupling capacitors are placed in series with the load, while decoupling capacitors are placed in parallel with the source and load. Decoupling capacitors also provide high transient currents to integrated circuits (ICs). This reduces power ripples and stabilizes voltage levels. Placing these capacitors close to the power pins of an IC creates a low-impedance path from the power supply to the ground.

By preventing interference, capacitors ensure clear signal transmission. This is especially important in rf and microwave applications, where signal integrity is critical.

Energy Storage

Capacitors excel in energy storage applications, particularly in renewable energy systems and electric vehicles. They stabilize power output from renewable sources, reducing wear on generators and extending the lifespan of electrical devices. Capacitors also smooth out power output fluctuations, ensuring seamless integration into the grid.

In electric vehicles, capacitors provide backup power during grid failures. They also assist in voltage regulation, preventing fluctuations that could damage sensitive components. By improving the power factor, capacitors reduce energy consumption and lower reliance on fossil fuels. This leads to reduced operational costs and carbon emissions.

Capacitors are also vital in specialized applications like medical implantables. Their ability to store and release energy reliably ensures the consistent operation of life-saving devices.

Timing Circuits

Capacitors are essential in timing circuits, where they work with resistors to control signal delays. For example, RC timers use a resistor-capacitor combination to determine time intervals. You can find these circuits in devices like clocks, alarms, and oscillators. By charging and discharging at predictable rates, capacitors help create precise timing intervals.

In oscillators and microcontrollers, capacitors provide accurate timing capabilities. This precision ensures synchronized operation of electronic functions. For instance, in a microcontroller, capacitors stabilize the clock signal, enabling consistent performance. Their role in timing circuits makes them indispensable for applications requiring reliable and repeatable time delays.

Tip: When designing timing circuits, choose capacitors with stable capacitance values to ensure consistent performance over time.

Specialized Applications

Audio Systems

Capacitors enhance audio systems by improving signal quality and power stability. They perform several critical functions:

Separate AC and DC signals to prevent interference.

Filter frequencies to reduce noise and enhance desired audio signals.

Stabilize power supplies by smoothing voltage fluctuations.

Provide immediate charge during sudden load changes, preventing voltage dips.

Suppress noise by reducing electromagnetic interference (EMI) and radio frequency interference (RFI).

By performing these tasks, capacitors ensure clear and high-quality audio output. For example, in amplifiers, they filter out unwanted noise, allowing you to enjoy distortion-free sound.

Automotive Electronics

In automotive electronics, capacitors improve efficiency and reliability. They manage AC components to ensure a stable power supply. By selecting capacitors with the right resonant frequency, you can remove AC noise from DC signals. Capacitors also handle rapid charge and discharge cycles, minimizing heating loss and enhancing performance.

Modern vehicles rely on capacitors for various functions, such as stabilizing voltage in electric power steering systems and supporting regenerative braking. Their ability to handle high currents and temperatures makes them ideal for automotive applications.

Renewable Energy Systems

Capacitors play a vital role in renewable energy systems like solar and wind power. They store excess energy during high production periods and release it during low production. This helps stabilize the grid and ensures a consistent power supply.

Capacitors also smooth out power output variations caused by factors like cloud cover or wind speed changes. In solar power plants, they mitigate the effects of shading and dust. In wind farms, they compensate for fluctuations in wind direction. By improving grid stability, capacitors enhance the integration of renewable energy sources and reduce reliance on fossil fuels.

Note: When selecting capacitors for renewable energy systems, consider environmental factors like RoHS compliance and recyclable materials to promote sustainability.

Capacitors are essential in electronics, serving purposes like energy storage, filtering, decoupling, and timing. They stabilize power supplies, prevent interference, and enable precise timing in circuits. For example, electrolytic capacitors act as reservoirs in power supplies, while ceramic capacitors excel in high-frequency applications.

Each capacitor type offers unique strengths. Ceramic capacitors are compact and versatile, while electrolytic capacitors provide high capacitance. Film capacitors ensure stability, and supercapacitors handle rapid charge-discharge cycles. Choosing the right capacitor depends on your application’s requirements, such as capacitance, voltage rating, and physical size.

Tip: Always consult datasheets to understand key parameters like tolerance, polarization, and ESR. Matching these to your circuit ensures optimal performance and reliability.

FAQ

What happens if you use the wrong type of capacitor in a circuit?

Using the wrong capacitor can lead to circuit failure. For example, a polarized capacitor connected incorrectly may short-circuit or explode. Always check the voltage rating, capacitance, and polarity to match your application’s requirements.

How do you determine the correct capacitance value for your project?

You calculate the required capacitance based on your circuit’s needs. For filtering, use capacitors with higher capacitance. For timing circuits, calculate the RC time constant using the formula:T = R × C, where T is time, R is resistance, and C is capacitance.

Can capacitors replace batteries in energy storage?

Capacitors cannot fully replace batteries. They store energy for short durations and discharge quickly. However, supercapacitors work well in applications needing rapid charge-discharge cycles, like regenerative braking systems or backup power supplies.

Why do capacitors age over time?

Capacitors age due to environmental factors like heat, voltage stress, and humidity. Electrolytic capacitors degrade faster because their electrolyte evaporates. To extend lifespan, choose capacitors with higher temperature ratings and operate them within specified limits.

How do you safely discharge a capacitor?

To discharge a capacitor, connect a resistor across its terminals. Use a resistor with a high resistance value to avoid sudden energy release. Never short the terminals directly, as this can damage the capacitor or cause injury.

Tip: Always verify the capacitor is fully discharged before handling it to prevent electric shock.

See Also

Exploring Key Developments in Capacitor Technology Through History

An Overview of Various Capacitor Types and Their Characteristics

Essential Steps You Should Follow for Supercapacitor Testing

Explaining the Function of MAF Sensors in Automobiles

The Impact of Force Sensitive Resistors on Technology Progress