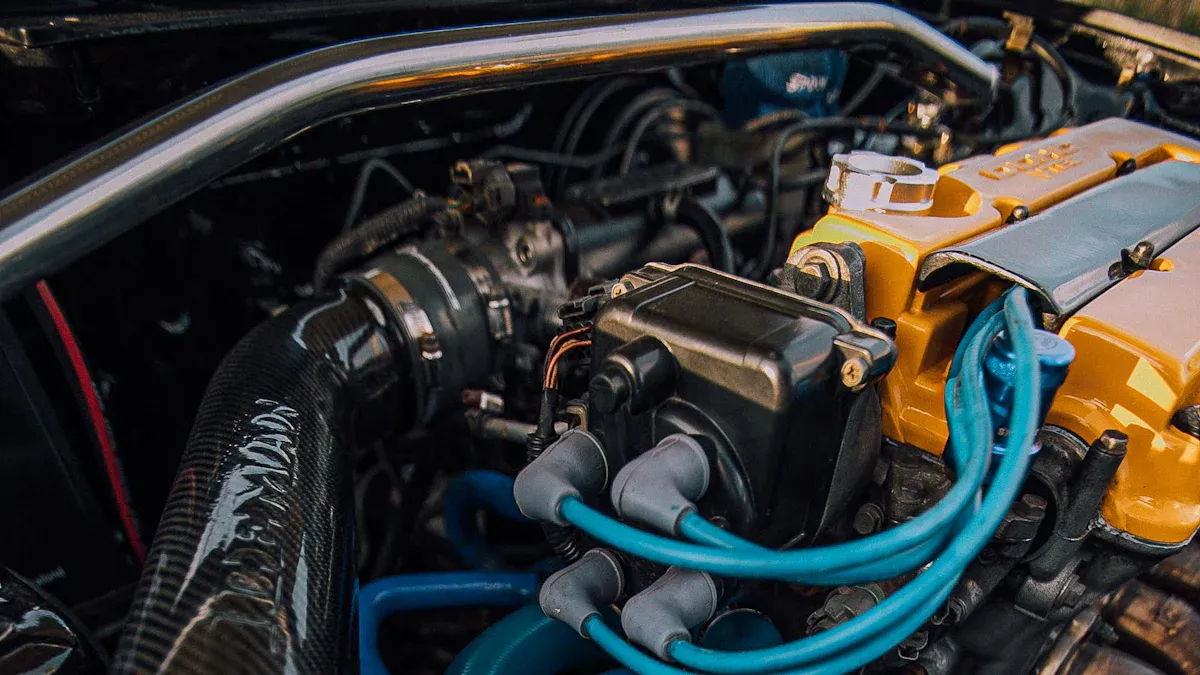

Coolant Temperature Sensors and Their Importance in Modern Vehicles

A coolant temperature sensor plays a crucial role in your car's functionality. If you're wondering, "What is coolant temperature sensor?"—it is a device that monitors the temperature of the engine's coolant. This sensor provides real-time data to the engine control unit (ECU), which then adjusts factors like fuel consumption and spark timing. These adjustments ensure the engine operates efficiently and avoids overheating.

Modern vehicles heavily rely on coolant temperature sensors to prevent engine issues. For instance, they can alert you before the engine overheats, potentially saving you from costly repairs. Back in 1995, cars typically had around 10 sensors, but by 2010, that number had increased to over 30. This growth highlights how sensors, including the coolant temperature sensor, contribute to making cars safer and more reliable.

Key Takeaways

A coolant temperature sensor checks how hot the engine coolant is.

It helps the engine work well and avoids overheating problems.

The sensor sends information to the engine's computer to adjust fuel and spark.

Cleaning and checking the sensor often can make it last longer.

If your car uses too much gas or won’t start easily, the sensor might be bad.

A scanner tool can quickly find problems with the sensor.

Fixing a broken sensor can stop big repairs and keep your car running well.

Always check your coolant levels to avoid engine overheating or damage.

If your engine overheats or the temperature gauge acts weird, ask a mechanic.

What Is a Coolant Temperature Sensor?

Definition and Function

A coolant temperature sensor is a small but important part of your car. It checks how hot or cold the engine coolant is and sends this info to the engine control unit (ECU). The ECU uses this data to make changes that keep the engine working well.

The sensor sends a voltage signal to the ECU.

This voltage changes based on the coolant's temperature.

The ECU uses this to adjust fuel, spark timing, and more.

This sensor keeps the engine at the right temperature. It stops overheating and helps save fuel. Without it, the engine might not work properly and could get damaged.

How It Works with the Engine Control Unit (ECU)

The coolant temperature sensor works closely with the ECU in modern cars. When the engine heats up, the sensor's resistance drops. This change affects the voltage sent to the ECU. The ECU reads this signal to know the engine's temperature.

The ECU then adjusts these engine settings:

Fuel Injection: A cold engine needs more fuel; a warm one needs less.

Ignition Timing: The ECU changes when the spark plug fires for better burning.

Emission Control: Keeping the engine at the right temperature lowers pollution.

This teamwork between the sensor and ECU keeps the engine running well, saves fuel, and reduces harm to the environment.

Types of Coolant Temperature Sensors

There are different kinds of coolant temperature sensors, each with pros and cons. Here's a simple comparison:

Sensor Type | Advantages | Limitations |

|---|---|---|

Thermistor | Works in a small range, less durable | |

Thermocouple | Handles high heat, strong, and fast | Less accurate, needs extra parts to work |

RTD Sensor | Very accurate, steady, and works in big ranges | Expensive, slower, and less tough |

Thermistors are cheap and great for cars.

Thermocouples handle very hot places like factories.

RTD Sensors are used where exact temperatures matter, like labs.

Knowing these types helps you pick the best one for your car or job.

Why Is the Engine Coolant Temperature Sensor Important?

Role in Engine Performance and Efficiency

The engine coolant temperature sensor is key to keeping your car running well. It helps the engine stay at the right temperature, avoiding overheating or running poorly. By checking the coolant's temperature, it helps the ECU adjust fuel and spark timing. These changes save fuel and keep the engine working smoothly.

The sensor tells the ECU to turn on the radiator fan when the engine gets too hot.

It reacts quickly, in less than five seconds, to big temperature changes.

Keeping the engine cool protects important parts like the engine and battery.

Without this sensor, the cooling system would not work as well. This could cause poor performance and expensive repairs.

Impact on Fuel Injection and Ignition Timing

The engine coolant temperature sensor affects how fuel is used and sparks are timed. When the engine is cold, it signals the ECU to add more fuel for better burning. As the engine warms up, it adjusts fuel levels for best performance. This helps save gas while driving.

The sensor also helps with ignition timing. It decides when the spark plug should fire for the best burn. This improves how the engine runs and uses less fuel. By managing these things, the sensor makes your car more efficient.

Tip: If your car uses too much gas or feels slow, the sensor might be broken.

Contribution to Emission Control and Environmental Benefits

The coolant temperature sensor helps cut down on pollution. It keeps the engine at the right temperature for complete fuel burning. This lowers harmful gases like carbon monoxide and nitrogen oxides.

New rules make good sensors important for meeting emission standards. Cars today need these sensors to save fuel and reduce pollution. A working sensor helps your car run better and keeps the air cleaner.

Note: Take care of the sensor to keep your car eco-friendly and avoid fines for failing emissions tests.

Symptoms of a Faulty Coolant Temperature Sensor

Overheating Engine

A broken temperature sensor can mess up the cooling system. This can make the engine overheat because the sensor might not send correct temperature data to the ECU. Without this info, the ECU can't turn on the radiator fan or manage cooling properly.

You may see the temperature gauge rise too high or steam from the hood. Ignoring these signs can seriously harm the engine, like bending cylinder heads or breaking a gasket. Fixing the problem quickly can save money and protect the engine.

Tip: If your engine overheats often, check the cooling system and sensor for problems.

Poor Fuel Economy

A bad temperature sensor can lower your car's fuel efficiency. Wrong data from the sensor can make the ECU add too much fuel. For example, if the sensor says the engine is cold when it's not, the ECU might use extra fuel.

This wastes gas and increases pollution. You might need to refuel more often, which costs more money. Replacing the sensor can fix fuel injection and improve efficiency.

Note: Keeping the cooling system and coolant levels in good shape can stop fuel problems caused by the sensor.

Difficulty Starting the Engine

A faulty sensor can make starting the car harder. The sensor helps the ECU decide the right fuel-air mix and ignition timing. If it fails, the ECU might struggle, especially in cold weather.

Other sensors, like crank or cam position sensors, can also cause starting issues. Tools like multimeters or oscilloscopes can check sensor performance and find the problem. If your car won't start or hesitates, testing the coolant sensor is important.

Reminder: If you're unsure about fixing or testing sensors, ask a mechanic for help.

Check Engine Light Activation

A broken coolant temperature sensor can turn on the check engine light. This light warns you about problems in your car. If the sensor sends wrong info to the ECU, it messes up the cooling system. The ECU notices this and switches on the warning light.

You can check if the sensor is the issue with an OBD-II scanner. This device reads error codes from the ECU to find the problem. Codes like P0115 or P0117 often mean the sensor is faulty. Ignoring the light can lead to bigger issues like overheating or wasting fuel. Fixing the problem quickly keeps your engine running well and avoids expensive repairs.

Tip: If the check engine light is on, don’t drive far. Fix the issue first to protect your engine.

Erratic or Inaccurate Temperature Gauge Readings

The temperature gauge shows how hot your engine is. A bad coolant temperature sensor can make the gauge act weird or show wrong numbers. For example, the needle might jump around or stay stuck.

This happens because the sensor doesn’t send correct info to the ECU. The cooling system might not work right because of this. You could see the radiator fan turn on at the wrong time or not work at all. These problems can cause overheating or poor cooling.

To check the sensor, look for damage or rust. You can also use a multimeter to test its resistance. Replacing the sensor fixes the gauge and helps the cooling system work properly.

Note: Watching your temperature gauge often can catch problems early. This prevents engine damage and keeps your car running smoothly.

How to Diagnose and Test a Coolant Temperature Sensor

Using an OBD-II Scanner for Error Codes

Finding problems with your coolant temperature sensor often starts with an OBD-II scanner. This device reads error codes stored in your car’s computer. These codes help find issues with the sensor or other parts.

Here’s how to use an OBD-II scanner:

Plug the scanner into the OBD-II port under the dashboard.

Turn on the ignition, but don’t start the engine.

Follow the scanner’s steps to get the error codes.

Some auto parts stores offer free code reading services. You can also use a Bluetooth OBD-II adapter with a phone app for similar results. Codes like P0115 or P0117 often mean the engine coolant temperature sensor has a problem.

Tip: Buying an OBD-II scanner can save time and money by spotting problems early.

Testing the Sensor with a Multimeter

A multimeter is another tool to check your coolant temperature sensor. It measures resistance and voltage to see if the sensor works.

Follow these steps to test the sensor:

Open the hood and find the sensor near the engine.

Unplug the sensor’s electrical connector.

Set the multimeter to measure resistance (ohms).

Touch the multimeter probes to the sensor terminals.

The resistance should change as the sensor heats up. If it doesn’t, the sensor might be broken. You can also check the coolant’s quality. Set the multimeter to DC volts under 20 volts. Place the black probe on the battery’s negative terminal and the red probe in the coolant. A reading below 0.4 volts means the coolant is in good shape.

Note: Always test when the engine is cool to avoid burns.

Inspecting for Physical Damage or Corrosion

Sometimes, just looking at the coolant temperature sensor can show problems. Check for cracks, broken wires, or rust. Corrosion on the sensor or its connector can stop it from working.

To inspect the sensor:

Take it out of the engine using the right tools.

Look for rust, dirt, or leaks around the sensor.

Clean it with a soft cloth or contact cleaner.

If the sensor is damaged or very rusty, replace it. Checking the sensor regularly can stop bigger problems and keep your car running well.

Reminder: Be gentle with the sensor to avoid breaking it during inspection.

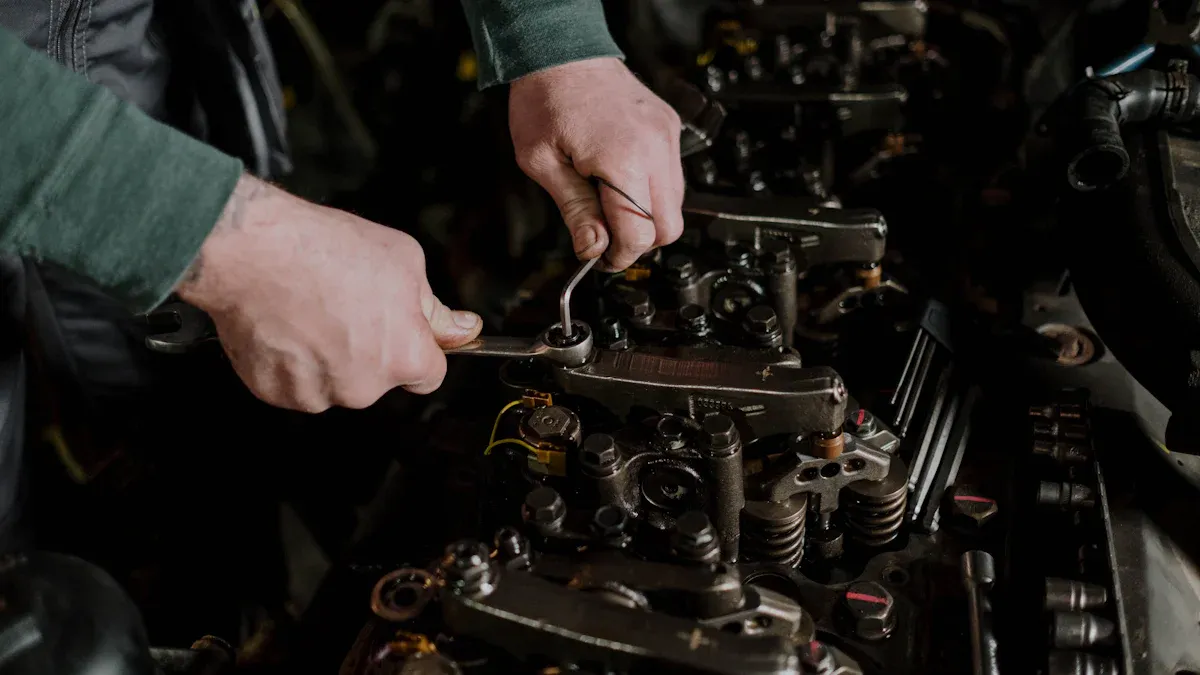

Steps to Replace a Faulty Coolant Temperature Sensor

Tools Needed for Replacement

To replace a coolant temperature sensor, you’ll need certain tools. These tools help make the process easier and safer. Below is a list of important tools:

Tool/Guide | Purpose |

|---|---|

Helps remove and install the sensor. | |

EXO Service Plan Brochure | Gives tips for sensor care and replacement. |

HydroMet Brochure | Shares details about sensor-related tools. |

Municipal Water Catalog | Lists tools for maintaining coolant systems. |

SmartQC Handbook | Explains quality checks during sensor changes. |

EXO Deployment Tube Guide | Useful for long-term sensor setups. |

YSI Field Kit Guide | A guide for working with sensors in the field. |

These tools ensure accuracy and prevent damage while replacing the sensor. Always check your car’s repair manual for instructions specific to your engine.

Easy Steps to Replace the Sensor

Here’s how to replace the coolant temperature sensor step by step:

Cool the Engine: Wait at least an hour for the engine to cool.

Disconnect Battery: Remove the negative terminal to avoid electrical shocks.

Wear Safety Gear: Use gloves and goggles to stay safe from hot coolant.

Find the Sensor: Look near the radiator or thermostat housing. Check your manual for help.

Remove Engine Cover: If needed, take off the cover using a wrench.

Drain Coolant: Empty the coolant to avoid spills when removing the sensor.

Unplug Sensor Wiring: Gently disconnect the wiring from the sensor.

Loosen Sensor: Use a wrench to loosen it. Spray release oil if it’s stuck.

Clean Threads: Clear dirt from the threads where the new sensor will go.

Install New Sensor: Screw in the new sensor by hand. Tighten it with a torque wrench as per the manual.

Reconnect Wiring: Clean the connector and plug it back into the sensor.

Refill Coolant: Add coolant to the recommended level.

Check for Leaks: Look around the sensor for any leaks.

Reconnect Battery: Attach the negative terminal of the battery.

Test the Sensor: Start the car and check if the temperature gauge works.

Tip: Watching a video tutorial can make the process easier to understand.

Safety Tips for Sensor Replacement

Safety is very important when changing the coolant temperature sensor. Follow these tips to protect yourself and your car:

Check the area for dangers like hot surfaces or coolant leaks.

Turn off power and disconnect the battery before starting.

Wear gloves and goggles to stay safe.

Use safe tools to avoid sparks or damage.

Work in a well-ventilated area if indoors.

Handle the sensor gently to avoid breaking it.

Test the new sensor after installing it to ensure it works.

Dispose of old coolant and parts properly.

Reminder: Always read your car’s repair manual for safety steps specific to your engine.

Maintenance Tips for a Coolant Temperature Sensor

Checking and Cleaning the Sensor Regularly

Looking after your coolant temperature sensor can save money and keep your engine running well. Check the sensor often, depending on how much you drive. For most cars, this can be monthly or yearly. During checks, look for cracks, rust, or other damage. Cleaning is also important. Follow the maker's instructions and avoid rough tools that might scratch the sensor.

Here are some easy tips to care for your sensor:

Write down every checkup and cleaning you do.

Test the coolant for dirt and make sure it flows well.

Use covers or pads to protect the sensor from heat or shaking.

Learn how to handle the sensor carefully to avoid breaking it.

By doing these things, your sensor will last longer and help your cooling system work better.

Keeping an Eye on Coolant Levels and Quality

Watching your coolant levels and quality is key to keeping your engine cool. If the coolant is low or dirty, it can cause overheating or damage. Check the coolant at least once a month and always before long drives. Use the chart below to know when to check or change your coolant:

Task | How Often |

|---|---|

Check coolant levels | Once a month |

Check coolant before long trips | Before every long trip |

Flush and replace coolant | Every 30,000 miles or 2 years |

When checking, see if the coolant looks dirty or has bits in it. If it does, it’s time to flush and replace it. Always use the coolant type your car’s maker suggests to avoid problems.

Knowing When to See a Mechanic

Sometimes, you’ll need a mechanic to fix bigger problems. If your car overheats a lot or the temperature gauge acts weird, get help. Mechanics have special tools to find and fix issues with the coolant temperature sensor or cooling system.

They can also do advanced tests, like checking the sensor’s accuracy or how well the coolant flows. If you’re not sure how to replace a sensor or flush the coolant, let a mechanic handle it. Fixing problems early with expert help can stop bigger, costly repairs later.

Tip: Keep a log of all visits to the mechanic. This helps you track your car’s care and stay on schedule.

A coolant temperature sensor is important for keeping your engine safe. It helps the engine work well by stopping overheating and saving fuel. Cleaning and checking the sensor often can make it last longer and prevent sudden problems. Replacing a broken sensor on time avoids expensive fixes and keeps your car running well.

Tip: Fix sensor problems quickly when you spot them. Acting early protects your engine and prevents bigger issues later.

FAQ

What does a coolant temperature sensor do?

The sensor checks how hot or cold the engine coolant is. It sends this info to the ECU, which adjusts fuel, spark timing, and cooling to keep the engine running well.

How can I tell if my coolant temperature sensor is faulty?

Watch for signs like overheating, bad gas mileage, or trouble starting. A check engine light or a temperature gauge acting weird can also mean sensor problems.

Can I drive with a bad coolant temperature sensor?

You can, but it’s not safe. A broken sensor might cause overheating or poor engine performance. Fixing it quickly avoids bigger problems and keeps your car working right.

How often should I check my coolant temperature sensor?

Check it during regular car maintenance or if you notice issues. A good rule is to inspect it every year or every 12,000 miles.

Is replacing a coolant temperature sensor expensive?

Replacing it isn’t too costly. The price depends on your car and labor fees. Doing it yourself can save money if you have the right tools.

What tools do I need to replace the sensor?

You’ll need gloves, goggles, a wrench, and maybe a torque wrench. A repair guide for your car can help you follow the steps.

Does a faulty sensor affect fuel efficiency?

Yes, it does. A bad sensor gives wrong info to the ECU, which can waste fuel. Replacing it helps your car use gas more efficiently.

Can I clean a coolant temperature sensor instead of replacing it?

Yes, if it’s dirty or rusty, you can clean it. Use a soft cloth and cleaner. If cleaning doesn’t work, you’ll need to replace it.

Tip: Taking care of your cooling system helps your sensor last longer.

See Also

The Importance of Engine Coolant Temperature Sensors for Efficiency

How Oxygen Sensors Influence Exhaust System Functionality

Maintaining Mass Air Flow Sensors for Peak Engine Performance

Exploring Transmission Speed Sensors and Their Impact on Vehicles

The Function of Crank Angle Sensors in Automotive Performance