Understanding What a MAF Sensor Does for Cars

The Mass Airflow (MAF) sensor, or what is a MAF sensor, plays a critical role in your car's engine system. It measures the amount of air entering the engine, providing essential data to the engine control unit (ECU). This information helps the ECU adjust fuel injection and ignition timing, ensuring the engine runs smoothly. By maintaining the correct air-fuel balance, the MAF sensor prevents over-fueling or under-fueling. This not only improves fuel efficiency but also reduces harmful emissions. Without an accurate MAF sensor, or what is a MAF sensor, your car's performance and efficiency could suffer, leading to higher fuel consumption and potential engine issues.

Key Takeaways

The MAF sensor checks how much air goes into the engine. This helps the ECU adjust fuel for better performance.

A working MAF sensor saves gas and lowers pollution. This helps both your money and the planet.

Cleaning the MAF sensor regularly is important. It stops problems and helps the engine last longer.

Signs of a bad MAF sensor include using more gas, engine stopping, and the check engine light turning on.

If you think the MAF sensor is bad, look at it closely. Use an OBD2 scanner to find error codes.

You can replace a bad MAF sensor yourself. But ask a pro if you're unsure about electrical parts.

Keep the air filter clean and check for leaks. This protects the MAF sensor and keeps it working right.

Fixing MAF sensor issues early saves money. It also keeps your car running well.

What Is a MAF Sensor?

Definition and Purpose of a MAF Sensor

A Mass Airflow Sensor (MAF) is a critical component in modern vehicles. It measures the volume of air entering the engine and sends this data to the Engine Control Unit (ECU). This information helps the ECU calculate the ideal air-fuel mixture for combustion. By ensuring the right balance, the MAF sensor supports efficient fuel usage and optimal engine performance.

The MAF sensor works in different ways depending on its type. For example:

Hot Wire MAF Sensors: These use a heated wire that cools as air flows over it. The ECU monitors the electrical current needed to maintain the wire's temperature, which helps determine the airflow.

Vane Meter MAF Sensors: These older models use a spring-loaded flap to measure the air entering the engine.

Both designs aim to provide accurate airflow data, but hot wire sensors are more common in modern vehicles due to their precision and reliability. Without a functioning MAF sensor, your car may struggle with poor fuel economy, reduced power, or increased emissions.

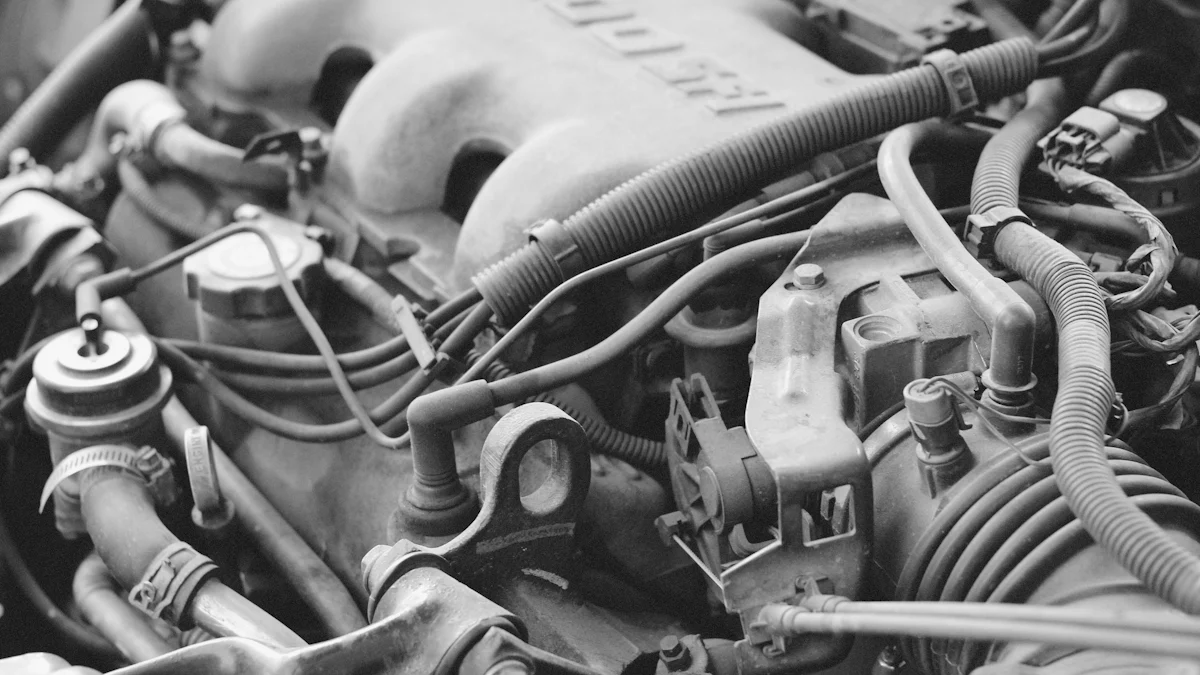

Location of the MAF Sensor in a Vehicle

The MAF sensor is typically located between the air filter and the intake manifold. Its placement allows it to measure the air entering the engine before it mixes with fuel. However, the exact location can vary depending on the vehicle model.

For instance:

Vehicle Model | |

|---|---|

1997-2003 Ford F-150 | Inside the air filter housing |

2007-2013 Chevrolet Silverado | On the intake hose |

If you're unsure where to find the MAF sensor in your car, check your vehicle's manual. Identifying its location is essential for maintenance or replacement.

By understanding what a MAF sensor does and where it is located, you can better appreciate its role in keeping your car running efficiently.

How Does a MAF Sensor Work?

The Function of an Air Flow Sensor

The mass airflow sensor plays a vital role in your car's engine system. It measures the amount of air entering the engine and sends this data to the engine control unit (ECU). This information helps the ECU determine the correct air-fuel mixture for combustion. Without accurate readings from the air flow sensor, your engine may run too rich or too lean, leading to poor performance or increased emissions.

The basic principles behind the operation of a MAF sensor are straightforward:

A hot wire MAF sensor contains a thermistor, a platinum hot wire, and an electronic control circuit.

The thermistor measures the temperature of the incoming air.

The hot wire is kept at a constant temperature by the control circuit.

As air flows over the wire, it cools down, causing the circuit to increase the current to maintain the wire's temperature.

The control circuit measures this current and converts it into a voltage signal that represents the airflow.

This process ensures that your engine receives the precise amount of air it needs for efficient combustion.

Types of MAF Sensors

There are two main types of mass airflow sensors: hot wire MAF sensors and vane meter MAF sensors. Each type operates differently and has unique advantages.

Hot Wire MAF Sensors

Hot wire MAF sensors are the most common type found in modern vehicles. They use a heated wire to measure the mass of incoming air. As air passes over the wire, it cools down, and the sensor measures the change in electrical resistance to calculate airflow.

These sensors offer several benefits:

They respond quickly to changes in airflow.

They have no moving parts, making them more durable.

They are compact and less expensive compared to other designs.

They work well in both gasoline and diesel engines.

However, hot wire sensors require regular maintenance. Dirt and oil can contaminate the wire, reducing its accuracy. The wire is also fragile and can break if handled improperly.

Vane Meter MAF Sensors

Vane meter MAF sensors are an older design. They use a spring-loaded flap that moves as air flows into the engine. The position of the flap determines the amount of air entering the engine.

While these sensors are reliable, they have some drawbacks:

They create more airflow restriction compared to hot wire sensors.

They are larger and less precise.

They are more sensitive to mounting orientation.

Despite these limitations, vane meter sensors were widely used in older vehicles due to their simplicity.

Disadvantages of Hot Wire MAF Sensors | |

|---|---|

Responds very quickly to changes in air flow | Dirt and oil can contaminate the hot-wire deteriorating its accuracy |

Low airflow restriction | Installation requires a laminar flow across the hot-wire |

Smaller overall package | The sensor contains a thin platinum wire, which can break if handled incorrectly |

Less sensitive to mounting location and orientation | N/A |

No moving parts improve its durability | N/A |

Less expensive | N/A |

Separate temperature and pressure sensors are not required | N/A |

Understanding how these sensors work and their differences can help you appreciate their role in maintaining your car's performance.

Why Is the MAF Sensor Important for Vehicle Performance?

Role in Regulating the Air-Fuel Mixture

The MAF sensor plays a crucial role in ensuring your engine receives the correct air-fuel mixture for combustion. It measures the amount of air entering the engine's intake system and sends this data to the engine control unit (ECU). The ECU then calculates the ideal air-fuel ratio (AFR), which is typically set at 14.7:1 for most vehicles. This ratio ensures efficient combustion under normal driving conditions.

Different driving scenarios require adjustments to the AFR. For instance:

During acceleration, the engine needs a richer AFR to produce more power.

While cruising, a leaner AFR improves fuel efficiency.

By providing accurate airflow data, the MAF sensor helps the ECU make these adjustments in real time. Without a properly functioning MAF sensor, your engine might run too rich or too lean, leading to poor performance and increased emissions.

Impact on Fuel Efficiency and Emissions

A properly working MAF sensor directly impacts your car's fuel efficiency. By maintaining the optimal air-fuel mixture, it ensures that your engine burns fuel as efficiently as possible. This reduces fuel consumption, saving you money at the pump.

In addition to improving efficiency, the MAF sensor also helps minimize harmful emissions. When the air-fuel mixture is balanced, the combustion process produces fewer pollutants. However, a faulty MAF sensor can disrupt this balance, causing your engine to burn fuel inefficiently. This not only increases emissions but may also lead to a failed emissions test.

Maintaining a clean and functional MAF sensor is essential for both your wallet and the environment.

Contribution to Engine Longevity

The MAF sensor also plays a significant role in preserving your engine's longevity. When the air-fuel mixture is incorrect due to a malfunctioning sensor, it can cause long-term damage to your engine. For example, running too rich can lead to carbon buildup, while running too lean may cause overheating.

Over time, these issues can harm critical components like the catalytic converter, which is expensive to replace. Addressing MAF sensor problems early can prevent these costly repairs and keep your engine running smoothly for years.

A well-maintained MAF sensor ensures your engine operates efficiently and avoids unnecessary wear and tear. This not only extends the life of your engine but also enhances your overall driving experience.

Signs of a Faulty MAF Sensor

Common Symptoms of a Malfunctioning MAF Sensor

A failing MAF sensor can cause noticeable issues in your vehicle's performance. Recognizing these symptoms early can help you avoid costly repairs. Here are some common signs to watch for:

Poor Fuel Economy: If you notice your car consuming more fuel than usual, the mass airflow sensor might not be providing accurate data to the engine control unit. This can lead to an improper air-fuel mixture, causing inefficient combustion.

Engine Hesitation or Stalling: A malfunctioning MAF sensor can disrupt the air-fuel balance, leading to rough idling, hesitation during acceleration, or even stalling. These issues often occur because the engine isn't receiving the correct amount of air or fuel.

Check Engine Light Activation: One of the most obvious signs of a failing MAF sensor is the illumination of the check engine light on your dashboard. This warning light often indicates that the sensor is sending incorrect or no data to the ECU.

Other symptoms may include reduced power, black smoke from the exhaust, or jerking during acceleration. Paying attention to these signs can help you address the problem before it worsens.

Troubleshooting a MAF Sensor

If you suspect your MAF sensor is faulty, you can take several steps to diagnose and resolve the issue. Here's a step-by-step guide to troubleshooting a MAF sensor:

Visual Inspection: Start by checking the sensor for visible damage, dirt, or loose connections. Ensure the wiring and connectors are secure.

Use an OBD2 Scanner: Plug in an OBD2 scanner to retrieve error codes related to the MAF sensor. Codes like P0101 or P0102 often point to airflow sensor problems.

Check MAF Sensor Readings: Monitor real-time airflow readings using diagnostic tools. Compare these values with your vehicle's specifications to identify discrepancies.

Test with a Multimeter: Measure the sensor's resistance and voltage output. Abnormal readings may indicate a failing MAF sensor.

Clean the MAF Sensor: Dirt and debris can interfere with the sensor's accuracy. Use a specialized MAF sensor cleaner to remove contaminants and restore functionality.

Replace the MAF Sensor: If cleaning doesn't resolve the issue, replacement may be necessary. Ensure you choose a sensor compatible with your vehicle.

Perform a Driving Cycle: After repairs, drive your car to recalibrate the ECU and verify the problem is resolved.

By following these steps, you can identify and fix issues with your MAF sensor. Regular maintenance and cleaning can also prevent future problems, ensuring your vehicle runs smoothly.

How to Maintain a MAF Sensor

Cleaning the MAF Sensor

Keeping your mass airflow sensor clean is essential for maintaining its accuracy and ensuring your engine runs efficiently. Over time, dirt and debris can accumulate on the sensor, leading to inaccurate readings and potential performance issues. Cleaning the sensor is a straightforward process that you can handle with the right tools and precautions.

Follow these steps to clean your MAF sensor effectively:

Locate the Sensor: Find the MAF sensor between the air filter housing and the intake manifold.

Turn Off the Engine: Ensure the vehicle is off and has cooled down before starting.

Disconnect the Sensor: Carefully unplug the electrical connector and remove any screws or clamps holding the sensor in place.

Use a Specialized Cleaner: Spray a dedicated MAF sensor cleaner onto the sensor element and its housing. Avoid touching the sensor wires, as they are delicate.

Avoid Harsh Chemicals: Stick to cleaners designed for MAF sensors to prevent damage.

Let It Air Dry: Allow the sensor to dry completely before reinstalling it.

Reinstall and Test: Reattach the sensor, reconnect the electrical connector, and start the engine to ensure it runs smoothly.

Regular cleaning, especially during air filter changes, can prevent issues caused by a failing MAF sensor. This simple maintenance step helps keep your sensor in optimal condition and avoids the need for frequent troubleshooting.

Preventative Measures to Avoid Issues

Preventing problems with your MAF sensor starts with good maintenance habits. By taking a few proactive steps, you can extend the life of your sensor and avoid costly repairs.

Here are some preventative measures you can follow:

Keep the Air Filter Clean: A clean air filter prevents dirt and debris from reaching the MAF sensor. Replace the air filter regularly to maintain proper airflow.

Inspect for Leaks: Check the air intake system for loose or cracked hoses. Unfiltered air entering the system can damage the sensor.

Use High-Quality Fuel: Lower-grade fuel can produce more contaminants, which may affect the sensor over time.

Avoid Aftermarket Intakes: Non-standard air intakes can disrupt airflow readings, leading to sensor issues. Stick to manufacturer-recommended parts.

Perform Routine Cleaning: Clean the MAF sensor during air filter changes to remove any buildup.

Maintain the Fuel Injection System: Periodically inspect and service the fuel injection system to ensure it operates efficiently.

By following these steps, you can reduce the likelihood of encountering a failing MAF sensor. Preventative care not only saves you money but also ensures your vehicle continues to perform at its best.

Replacing a Faulty MAF Sensor

When to Replace the MAF Sensor

Knowing when to replace the mass airflow sensor in your vehicle can save you from costly repairs. Several signs indicate that the sensor may need replacement:

Rough idling, where the engine stutters or shakes when idle.

Poor fuel economy, as the engine consumes more fuel than usual.

Loss of power, making acceleration sluggish or unresponsive.

Black soot or smoke from the exhaust, signaling a rich fuel mixture.

A check engine light that points to airflow sensor issues.

Difficulty starting the engine or frequent stalling.

If you notice any of these symptoms, inspect the sensor promptly. While cleaning the sensor can resolve minor issues, persistent problems often require a replacement. Ignoring these signs can lead to further engine damage and increased emissions.

Steps for Replacing a MAF Sensor

Replacing a faulty MAF sensor is a straightforward process you can handle with basic tools. Follow these steps to ensure a successful replacement:

Disconnect the negative battery terminal to prevent electrical issues.

Unplug the electrical connector attached to the sensor.

Loosen the air intake hose clamp using a flathead screwdriver. Remove the air intake tube and air filter housing.

Inspect the sensor for dirt or damage. If it appears dirty, clean it with a specialized cleaner and allow it to dry. If cleaning doesn’t resolve the issue, proceed to the next step.

Use a ratchet and socket to remove the bolts securing the sensor to the intake tube.

Carefully slide the old sensor out of its housing.

Take the new sensor out of its packaging and slide it into place. Avoid touching the temperature sensor wire, as it is fragile.

Tighten the bolts to the manufacturer’s specifications, typically 15-20 ft-lbs.

Reinstall the air intake tube and reconnect the electrical plug. Tighten the hose clamp securely.

Reconnect the negative battery terminal.

Start the engine and check for any warning lights or performance issues.

These steps ensure the new sensor functions correctly and restores your vehicle’s performance.

Choosing Between Professional Help and DIY Replacement

Deciding whether to replace the MAF sensor yourself or seek professional help depends on your comfort level and experience. If you have basic mechanical skills and access to tools, a DIY replacement can save you money. The process is relatively simple and takes about 30-60 minutes.

However, if you’re unsure about handling electrical components or lack the necessary tools, consulting a professional mechanic is a safer option. Professionals can diagnose related issues, such as air intake leaks or ECU problems, that might affect the sensor’s performance. While this option costs more, it ensures the job is done correctly and prevents further complications.

Evaluate your skills and the complexity of the task before making a decision. Whether you choose DIY or professional help, addressing a faulty MAF sensor promptly will keep your vehicle running smoothly.

The maf sensor is vital for maintaining your vehicle's performance and efficiency. Regular maintenance ensures better fuel economy, lower emissions, and a smoother driving experience. Ignoring sensor issues can lead to costly repairs. For example:

A faulty sensor may cause rough idling or stalling.

Persistent air-fuel imbalances can damage the catalytic converter.

Engine harm from improper air-fuel ratios can escalate repair costs.

Addressing problems early prevents these issues and keeps your car running smoothly. Prioritize timely maintenance to enjoy long-term benefits and avoid unnecessary expenses.

FAQ

What happens if the MAF sensor fails?

A failing MAF sensor disrupts the air-fuel mixture. You may notice poor fuel economy, engine stalling, or reduced power. Ignoring the issue can lead to long-term engine damage. Addressing it promptly ensures your car runs efficiently.

Can you drive with a bad MAF sensor?

Driving with a faulty MAF sensor is possible but not recommended. It can cause poor performance, higher emissions, and potential engine damage. Fixing the issue quickly prevents further complications and ensures safe driving.

How often should you clean the MAF sensor?

Clean the MAF sensor every 12,000 to 15,000 miles or during air filter changes. Regular cleaning prevents dirt buildup, ensuring accurate readings and optimal engine performance.

How much does it cost to replace a MAF sensor?

The cost of replacing a MAF sensor ranges from $100 to $300, including parts and labor. DIY replacement can save money, but professional help ensures proper installation.

Can a dirty air filter damage the MAF sensor?

Yes, a dirty air filter allows debris to reach the MAF sensor. This contamination affects its accuracy, leading to performance issues. Replacing the air filter regularly protects the sensor.

What tools do you need to replace a MAF sensor?

You’ll need a flathead screwdriver, a ratchet with sockets, and a specialized MAF sensor cleaner. These tools make the replacement process straightforward and efficient.

Does a faulty MAF sensor trigger the check engine light?

Yes, a malfunctioning MAF sensor often activates the check engine light. Use an OBD2 scanner to confirm the issue and take appropriate action.

Can cleaning the MAF sensor fix performance issues?

Yes, cleaning the MAF sensor often resolves minor performance problems caused by dirt buildup. Use a dedicated cleaner and follow proper steps to restore functionality.

See Also

Understanding Camshaft Position Sensors And Their Functionality

Essential Tips for Selecting the Right Car Relays

Step-by-Step Guide to Testing Starters for Various Vehicles

Key Differences Between Inverters And Transformers Explained

Deciding on Electronic Versus Magnetic Ballasts for Your Requirements