What Makes a DAC Cable Different from Other Network Cables

A DAC, or direct attach cable, stands out from other network cables because of its twinaxial copper cable construction and factory-terminated connectors such as SFP+ and QSFP+. This high-speed cable enables reliable, low-latency connection for short distances in data centers and telecom. Unlike standard ethernet or optical cables, what is a dac cable offers measurable advantages:

Maintains latency well below 100 milliseconds, ideal for high-speed, latency-sensitive applications.

100G QSFP28 direct attach copper cables transmit data without signal conversion delays or high power use.

Loopback tests show extremely low bit error rates, ensuring dependable high-speed cable performance.

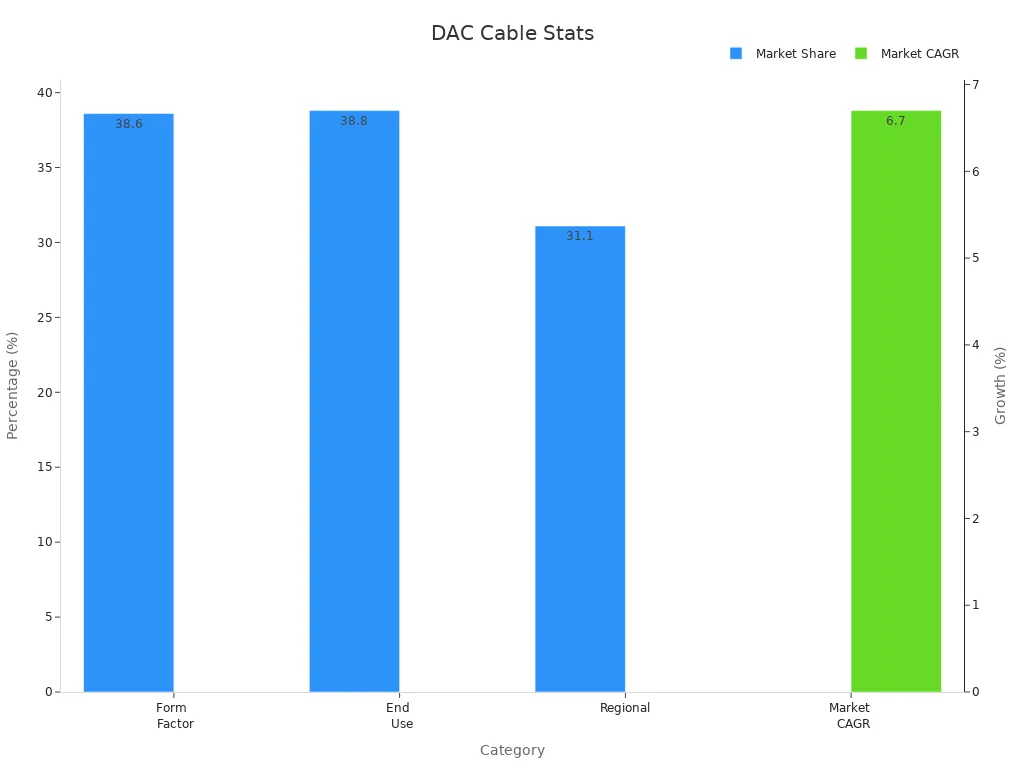

Industry leaders like Cisco and Mellanox trust direct attach cable for its efficiency and reliability. The chart below shows the growing role of DAC in the global market:

Understanding what is a dac cable and its differences helps network planners choose the right copper cable for high-speed ethernet connection needs.

Key Takeaways

DAC cables use twinaxial copper wires and fixed connectors for fast, low-latency data transfer over short distances.

They offer high speeds up to 400 Gbps, making them ideal for data centers and high-performance computing.

Passive DAC cables need no extra power and work best up to 7 meters; active DAC cables boost signals for longer runs up to 15 meters.

Compared to ethernet and fiber optic cables, DAC cables provide lower latency and cost for short-range connections.

DAC cables are easy to install with plug-and-play connectors, reducing setup time and complexity.

Their bulkier design and susceptibility to electromagnetic interference require careful cable management and placement.

DAC cables excel in data centers, HPC clusters, and enterprise networks where fast, reliable links are critical.

Choosing the right DAC cable type and length ensures optimal performance and helps avoid signal loss or errors.

What Is a DAC Cable

DAC Construction

A direct attach cable, often called a direct attach copper cable, uses twinaxial copper wire as its core. This copper cable features two inner conductors wrapped together, which helps reduce interference and maintain strong signal quality. Manufacturers factory-terminate each end of the direct attach cable with fixed connectors, such as SFP+ or QSFP+. These connectors make the cable ready for immediate use in network equipment.

The most common American Wire Gauge (AWG) sizes for direct attach copper cables range from 24 AWG to 30 AWG. Thicker cables, like 24 AWG, offer better performance but are less flexible. Thinner cables, such as 30 AWG, provide more flexibility and are easier to manage in tight spaces. The table below shows key technical specifications for what is a dac cable:

Specification Aspect | Details |

|---|---|

AWG Size Range | 24 AWG to 30 AWG |

Supported Data Rates | Up to 25 Gbps per channel for SFP28, 10 Gbps for SFP+, 40 Gbps for QSFP+ |

Cable Lengths | Typically 1 to 7 meters, extendable up to 10 meters |

Standards Compliance | IEEE 802.3bj |

Connector Types | SFP+, SFP28, QSFP+ |

Cable Type | Twinax copper wire |

Power Requirement | Passive cables, no external power needed |

Application | Short-distance, high-speed data center interconnects |

Direct attach copper cables support high-speed cable connections in environments where short distances and reliability matter most. Data centers and high-performance computing clusters often use these copper cables for fast, direct connections between switches, servers, and storage devices.

How DAC Works

A direct attach cable transmits data using electrical signals over its twinaxial copper cable. The direct attach copper design allows for high-speed data transfer with very low latency. Engineers test these cables using Bit Error Rate (BER) testing, which measures how many bits are transmitted incorrectly compared to the total sent. This process ensures that the direct attach cable maintains data integrity, even at high speeds.

Studies show that direct attach copper cables can achieve extremely low latency, sometimes as little as 100 nanoseconds. This makes them ideal for real-time applications in a data center. The direct attach cable supports high-speed ethernet connections without the need for separate transceivers, which reduces both cost and power use. High speed dac cables also outperform fiber optics in some short-range scenarios because they do not require signal conversion, which can introduce delays.

Direct attach copper cables work best for short distances, usually under 7 meters. They provide a reliable, high-speed cable solution for connecting network devices in the same rack or adjacent racks. The copper cable construction ensures that the signal remains strong and stable, even in environments with lots of electronic equipment.

DAC Connectors

Direct attach cable assemblies come with factory-installed connectors, such as SFP+ and QSFP+. These fixed connectors play a crucial role in the performance and simplicity of direct attach copper cables. The SFP+ connector, for example, acts as both the sender and receiver, allowing for direct, low-latency connections between network devices. This design eliminates the need for separate transceiver modules, making the direct attach cable a plug-and-play solution.

Tip: Fixed connectors like SFP+ and QSFP+ make direct attach copper cables easy to install and maintain. They also help reduce power consumption and lower the total cost of ownership.

SFP+ and QSFP+ connectors enable high-speed ethernet connections up to 10 Gbps and 40 Gbps, respectively.

The direct attach copper cable combines the cable and transceiver into one unit, which simplifies network setup.

These connectors support backward compatibility, so a direct attach cable can work with older network equipment.

Direct-attach copper cable assemblies are widely used in data center environments, where quick, reliable, and high-speed connections are essential. The combination of twinaxial copper cable and fixed connectors ensures that the signal remains strong and the connection stays stable, even in demanding network conditions.

DAC vs. Other Network Cables

DAC vs. Ethernet

A DAC cable and a standard ethernet cable serve different roles in network environments. DAC cables use twinaxial copper cable construction and come with factory-terminated connectors. Ethernet cables, such as Cat5e or Cat6, use twisted pair copper cable and require separate connectors. DAC cables support high-speed data rates up to 100 Gbps for short distances, usually less than 7 meters. Ethernet cables can reach up to 100 meters but often support lower speeds, especially in older categories.

DAC cables transmit data using direct electrical signals, which keeps latency very low. This feature makes them ideal for high-speed cable connections in data center racks. Ethernet cables also use electrical signals but may introduce more latency due to longer cable runs and additional network devices. DAC cables are more cost-effective for short-range, high-speed applications, while ethernet cables offer flexibility for longer distances.

Note: DAC cables simplify installation in high-density data center environments because of their pre-terminated connectors and plug-and-play design.

Key differences between DAC and Ethernet cables:

DAC cables provide low-latency, high-speed connections for short distances.

Ethernet cables offer longer reach but may not match the speed and latency of DAC cables in short-range scenarios.

DAC cables are more durable and flexible for high-density racks, while ethernet cables are better for general office networking.

DAC vs. Fiber Optic

DAC cables and fiber optic cables both support high-speed data transmission, but they differ in construction and performance. DAC cables use copper cable to send electrical signals, while fiber optic cables use glass or plastic fibers to transmit light signals. This difference affects distance, speed, and reliability.

Fiber optic cables can carry data over much longer distances, often exceeding 100 meters, and maintain high-speed performance with minimal signal loss. DAC cables work best for short connections, typically up to 7 meters, and may experience signal degradation or electromagnetic interference (EMI) over longer runs. Fiber optic cables are immune to EMI, making them more reliable in environments with lots of electronic equipment.

Feature | DAC Cables (Direct Attach Copper) | Fiber Optic Cables (AOC) |

|---|---|---|

Transmission Medium | Copper cable (electrical signals) | Optical fiber (light signals) |

Typical Distance | Up to 7 meters | 100 meters or more |

Data Rates Supported | Up to 400 Gbps | |

EMI Susceptibility | Susceptible | Immune |

Power Consumption | Low (passive) | Higher (active components) |

Flexibility & Weight | Lighter, more flexible | |

Cost | Lower | Higher |

Use Cases | Short-range, high-speed, cost-sensitive | Long-range, high-bandwidth, EMI-sensitive |

Fiber optic cables cost more and require more complex installation, but they offer better scalability and future-proofing for growing networks. DAC cables remain the best choice for short, high-speed connections within a single rack or between adjacent racks in a data center.

DAC vs. AOC

Active Optical Cables (AOC) combine the benefits of fiber optic technology with the convenience of pre-terminated connectors, similar to DAC cables. However, AOC cables use optical fibers and embedded transceivers to convert electrical signals into light and back again. This design allows AOC cables to support longer distances, up to 100 meters or more, and maintain high-speed data rates.

DAC cables, especially passive types, consume almost no power and offer very low latency. AOC cables require power for their active components but provide better signal integrity and are immune to EMI. DAC cables are heavier and bulkier, while AOC cables are lighter and easier to manage in dense cabling environments.

Feature | DAC (Direct Attach Copper) | AOC (Active Optical Cable) |

|---|---|---|

Construction | Twinaxial copper cable | Optical fiber with transceivers |

Signal Transmission | Electrical | Optical (light) |

Typical Distance | 1-7 meters | 10-100 meters or more |

Power Consumption | Low (passive) | Higher (active components) |

EMI Resistance | Susceptible | Immune |

Weight and Flexibility | Heavier, less flexible | Lighter, more flexible |

Cost | Lower | Higher |

Best Use Case | Long, high-speed, EMI-sensitive |

AOC cables excel in large-scale data center deployments where long-distance, high-speed connections are needed. DAC cables remain the preferred choice for short, direct connections between servers and switches, where cost, power savings, and low latency matter most.

Tip: Choose DAC cables for short, high-speed cable runs in a data center. Select AOC or fiber optic cables for longer distances or environments with high electromagnetic interference.

Types of Direct Attach Cable

Direct attach cables come in several types, each designed for specific network needs. The main categories include passive DAC, active DAC, and dac breakout cable. Understanding these types helps network planners select the right copper cable for their environment.

Passive DAC

A passive DAC uses twinaxial copper cable without any built-in electronics. This type of cable transmits data using direct electrical signals. It does not amplify or modify the signal, which limits its effective length to about 5 to 7 meters. Passive DAC cables work best for short-range connections, such as linking devices within the same rack. They support high data rates, sometimes up to 400 Gbps, but signal loss increases over longer distances. These cables do not require external power, making installation simple and cost-effective.

Passive DAC cables:

Do not boost or condition the signal.

Operate without external power.

Offer low latency and generate less heat.

Are best for short, high-speed connections.

Performance Metric | Passive DAC Cable Characteristics |

|---|---|

Maximum Data Rate | Up to 400 Gbps |

Maximum Cable Length | Typically up to 5-7 meters |

Signal Integrity | Maintained over short distances |

Latency | Very low |

Signal Amplification | None |

Bandwidth Limitations | Higher over longer distances |

Thermal Performance | Less heat generation |

Network engineers often choose passive DAC for its reliability and simplicity in short-distance, high-speed environments.

Active DAC

An active DAC also uses copper cable but includes electronic components that amplify the signal. These built-in electronics help maintain signal quality over longer distances, reaching up to 15 meters. The signal boosting feature allows active DAC cables to connect devices across different racks or areas within a data center. This type of cable requires external power and costs more than passive DAC, but it provides better performance for longer runs.

Active DAC cables:

Contain electronics for signal amplification.

Support longer cable runs, up to 15 meters.

Improve signal integrity and reduce loss.

Consume more power and cost more than passive types.

Note: Active DAC cables are ideal when network devices are farther apart but still need high-speed, reliable connections.

Direct vs. Breakout

Direct attach cables come in two main connection styles: direct and breakout. A direct DAC connects two devices with the same port type and speed, such as switch-to-switch or server-to-switch links. This setup uses a single copper cable with matching connectors on both ends.

A dac breakout cable, sometimes called a fanout cable, splits one high-speed port into several lower-speed ports. For example, a 40G QSFP+ port can break out into four 10G SFP+ ports using a dac breakout cable. This design increases port density and allows flexible connections between devices with different speeds.

Category | Description |

|---|---|

Passive DACs have no signal conditioning; Active DACs include electronics for signal boosting. | |

Breakout DAC Cables | One high-speed connector splits into multiple lower-speed connectors, increasing port density. |

Data Rate & Form Factor | DAC cables support various speeds and port types, such as SFP+, QSFP+, and QSFP28. |

Network teams use dac breakout cable solutions to connect switches with servers or storage devices that operate at different speeds. This flexibility makes dac breakout cable a popular choice in modern data centers.

DAC Advantages

Speed and Latency

DAC cables deliver outstanding speed and low latency in modern networks. Many data centers use OSFP DACs, which combine eight differential pairs to reach up to 400 Gbps total bandwidth. This high-speed performance supports real-time processing and fast data transfers. The cable design reduces signal loss and crosstalk, so communication stays reliable over short distances, usually between 0.5 and 2 meters.

DAC cables use copper conductors for direct electrical connections, which keeps latency very low.

Passive DAC cables transfer signals physically, without extra processing, so they provide minimal delay.

Active DAC cables can amplify or regulate signals, which helps maintain stability in noisy environments or over slightly longer distances.

400G QSFP-DD DACs are common in high-performance computing clusters, where high-speed and low-latency responses are critical for analytics and cloud applications.

These features make DAC cables a top choice for connecting switches, servers, and storage devices that need fast, high-speed links.

Cost and Power

DAC cables offer a cost-effective solution for short-range, high-speed connections. They use copper wires and modular interfaces, which lowers the price compared to fiber optic cables. Most DAC cables, especially passive types, do not need extra power or optical transceivers. This reduces both energy use and equipment costs.

DAC cables support evolving network speeds, such as 25G, 40G, 100G, and 400G, without raising costs sharply.

They provide low power consumption, which helps data centers save on electricity and cooling.

The simple design of DAC cables means fewer parts to buy and maintain.

For organizations that need high-speed connections within a rack or between nearby racks, DAC cables deliver strong performance without a high price tag.

Simplicity

The simplicity of DAC cables makes them easy to install and manage. These cables come as plug-and-play solutions, so network teams do not need highly trained staff for setup. Their small size and lightweight design help reduce cable clutter, especially in dense server racks.

DAC cables shorten installation time and lower operational overhead.

They simplify cable management by allowing short, direct connections between devices.

Passive DAC cables do not require power or optical transceivers, which further reduces deployment complexity.

Tip: The straightforward nature of DAC cables speeds up network rollouts and makes maintenance easier, even in large-scale environments.

Network managers often choose DAC cables for their high-speed performance, low cost, and ease of use. These advantages help organizations build efficient and reliable networks.

DAC Limitations

Length

DAC cables work best over short distances. Most passive DAC cables support lengths up to 7 meters. Active DAC cables can reach about 15 meters because they have built-in electronics that help boost the signal. When the cable gets longer, the signal can weaken. This can cause data errors or slow down the network. Manufacturers and industry standards set these length limits to keep data moving quickly and safely. Network planners must choose the right cable length for each connection. Using a cable that is too long can lead to problems with data integrity and speed. For this reason, DAC cables are most common inside a single rack or between racks that are close together.

Note: Always check the recommended cable length before installing a DAC cable to avoid performance issues.

Bulk and Flexibility

DAC cables use twinaxial copper wires, which makes them thicker and less flexible than many other network cables. This bulkiness can make it hard to manage cables in crowded server racks. When many DAC cables run together, they can take up a lot of space and block airflow. This can make cooling the equipment more difficult. Some thinner DAC cables are available, but they may not support the highest speeds or longest distances. Network engineers often need to plan carefully to fit DAC cables in tight spaces. They may use cable organizers or trays to keep everything neat.

DAC cables can be harder to bend or route around corners.

Large bundles of DAC cables may limit access to other equipment.

A table below shows how DAC cables compare to other types in terms of size and flexibility:

Cable Type | Thickness | Flexibility | Space Needed |

|---|---|---|---|

DAC | High | Low | More |

Fiber Optic | Low | High | Less |

Ethernet (Cat6) | Medium | Medium | Medium |

EMI Susceptibility

Electromagnetic interference (EMI) can affect DAC cables. Since these cables use copper wires, they can pick up noise from nearby electronic devices. This noise can cause errors in the data or even stop the connection from working. Fiber optic cables do not have this problem because they use light instead of electricity. In environments with lots of electrical equipment, EMI can be a big concern. Network teams may need to use shielding or special cable paths to protect DAC cables from interference.

Tip: Place DAC cables away from power lines and heavy machinery to reduce the risk of EMI.

Compatibility is another thing to consider. Not all network devices support every type of DAC cable. The size and stiffness of DAC cables can also make it hard to fit them in dense racks or small spaces. Careful planning helps avoid these issues and keeps the network running smoothly.

DAC Use Cases

Data Centers

Data centers rely on dac cables for fast and reliable connections. These cables link servers, storage, and networking equipment. Most data center interconnection tasks use dac cables because they offer low latency and high bandwidth. Operators choose dac cables for short distances, usually within the same rack or between adjacent racks. This setup helps keep costs low and installation simple.

Data centers represent the largest market for dac cables.

Dac cables provide high-speed, dependable links between critical devices.

Passive dac cables dominate because they are cost-effective and easy to install.

North America leads in dac cable use, with Asia Pacific growing quickly due to new digital infrastructure.

Form factors like SFP+, QSFP+, and QSFP28 play a key role. SFP+ supports up to 10 Gbps, QSFP+ up to 40 Gbps, and QSFP28 up to 100 Gbps. These connectors allow data centers to scale up as network speeds increase. Dac cables also help reduce power consumption and heat, supporting green data center initiatives.

Tip: Use dac cables for short, high-speed data center interconnection to save energy and simplify cable management.

HPC

High-performance computing (HPC) environments need fast, low-latency connections. Dac cables meet these needs by linking servers and switches inside racks. For example, the ALICE event processing nodes at CERN use dac cables to connect servers to top-of-rack switches. This setup supports data rates over 100 Gb/s and keeps latency low.

HPC clusters often use taller racks to place servers closer to switches. Dac cables work best for these short runs, usually under 3 meters. Engineers choose dac cables because they cost less than fiber optics and use less power. Stress tests in HPC labs show that dac cables handle heavy data loads without errors. As a result, HPC teams can expand their clusters easily by adding more servers and cables.

Enterprise Networks

Enterprise networks also benefit from dac cables. These networks use dac cables for switch-to-switch and server-to-switch links in high-speed data centers. Dac cables offer low latency and low bit error rates, making them reliable for business-critical applications. Enterprises prefer dac cables for short connections because they are passive, energy-efficient, and easy to deploy.

Attribute | DAC Cables (SFP+ DAC) | Fiber Optic Cables |

|---|---|---|

Kilometers | ||

Cost | Lower | Higher |

Latency | Lower | Higher |

Installation Ease | Plug-and-play | More complex |

Energy Efficiency | Higher | Lower |

Suitability | High-speed, short-distance | Long-distance, EMI-prone |

Dac cables support the growing needs of enterprise networks, especially as new technologies like AI and 5G demand faster connections. They help businesses build efficient, scalable, and sustainable networks.

DAC cables stand out for short-range, high-speed connections, offering low latency and cost savings. The table below highlights their main strengths and weaknesses:

Aspect | Advantages | Limitations |

|---|---|---|

Performance | Limited reach, bulkier design | |

Cost | Up to 70% cheaper than fiber | Not future-proof |

Use Cases | Data centers, high-density racks | Susceptible to EMI |

When selecting dac cables, network planners should check compatibility, avoid excessive bending, and shield cables from interference. Regular inspections and proper installation help maintain reliable performance.

FAQ

What does DAC stand for in networking?

DAC stands for Direct Attach Copper. It refers to a type of high-speed cable that uses copper wires and fixed connectors to connect network devices over short distances.

How far can a DAC cable reach?

Most passive DAC cables work up to 7 meters. Active DAC cables can reach about 15 meters. Longer distances may cause signal loss or errors.

Can DAC cables replace fiber optic cables?

DAC cables work well for short, high-speed connections. Fiber optic cables handle longer distances and avoid electromagnetic interference. Network engineers choose based on distance and environment.

Are DAC cables compatible with all switches?

Not all switches support every DAC cable. Users should check the switch’s specifications for supported connector types and data rates before buying.

What is the difference between passive and active DAC cables?

Passive DAC cables have no electronics and use direct electrical signals. Active DAC cables include electronics that boost the signal, allowing for longer cable runs.

Do DAC cables need extra power?

Passive DAC cables do not need extra power. Active DAC cables require power for their built-in electronics.

Where are DAC cables most commonly used?

Data centers, high-performance computing clusters, and enterprise networks use DAC cables for fast, reliable connections between servers, switches, and storage devices.

Are DAC cables easy to install?

Yes. DAC cables come with factory-installed connectors. Users can plug them in without special tools or training. This makes setup quick and simple.

See Also

Top Three Key Differences Between USB-C And USB

Why FFSD PCB Connectors Stand Out In Electronics Today

Understanding The Main Differences Between SDRAM And Async DRAM

Step-By-Step Instructions For Installing BNC Connectors Effectively