What Are the Key Factors Behind the Reliability of Transistors Versus Mechanical Relays

Transistors work faster and are more reliable than mechanical relays because they have no moving parts. They turn on and off very quickly. They also last much longer. Electronic devices need parts that work well every day. Engineers pick parts that can handle many uses and hard conditions.

A reliable system helps devices run safely and have fewer problems. People see that transistors are faster and more reliable than mechanical relays in most electronic circuits.

Key Takeaways

Transistors do not have moving parts. They switch faster and last longer than mechanical relays.

Mechanical relays wear out over time. Their moving parts cause friction, sparks, and damage to contacts.

Solid-state devices like transistors and solid-state relays do not wear out. They work better in dusty, shaky, or hot places.

Transistors use less power than mechanical relays. This helps devices save energy and make less heat.

Transistors can switch millions or billions of times each second. Mechanical relays switch much slower and wear out faster.

Mechanical relays are still helpful for strong electrical isolation. They are also good for switching very high voltage and current.

Transistors help make electronic devices smaller, lighter, and more reliable. They let millions of tiny switches fit on a chip.

You must pick the right part for the job. Use transistors for fast, frequent switching. Use relays for high power or safety isolation.

Basics

What Are Transistors?

Transistors are tiny devices that help control electricity in a circuit. They can work as switches or amplifiers. When you put voltage on the gate, current can move between the drain and source. For example, the AO3400 MOSFET can handle 30 volts and 5.8 amps. It has low resistance when it is on, so it does not waste much energy. Transistors turn on and off very fast. This makes them good for computers, phones, and other devices. How well they work depends on how fast charge moves, the channel length, and the contact resistance. These things help engineers pick the best transistor for each job.

Transistors have limits too. Each one can only take so much power before it gets too hot. They have ratings for how much voltage they can block and how fast they can switch. These ratings help keep devices safe and working well.

What Are Mechanical Relays?

Mechanical relays are switches that use magnets and moving parts to open or close circuits. They have a coil that makes a magnetic field when electricity flows through it. This field pulls a metal arm to move contacts and connect or disconnect the circuit. Relays have been used for a long time in telegraphs, phones, and old computers. They can control a lot of power with a small signal.

Relays use electromagnets to move contacts and control circuits.

Early relays helped send signals far and did logic in computers.

Some relays use semiconductors instead of moving parts; these are called solid-state relays.

Relays can do logic like AND, OR, and NOT by changing how contacts are set up.

Protective relays stop damage by finding faults and turning off circuits.

Designers use special metals like gold or silver for contacts to make them last longer.

Latching relays stay in their last spot even if power goes out, which helps in some systems.

How Operation Affects Reliability

How transistors and relays work changes how reliable they are. Transistors do not have moving parts, so they do not wear out from movement. They can turn on and off millions of times without breaking. Mechanical relays have parts that move each time they work. These parts can wear out or get dirty over time, which can make the relay stop working.

Researchers test these devices at high stress to see how they fail. They look for changes in how the devices break. For example, metal oxide semiconductor transistors in power systems fail in different ways under stress. Finding these changes helps engineers guess how long a device will last. Knowing when and why a device might fail helps engineers make safer and longer-lasting systems.

Aspect | Transistor | Mechanical Relay |

|---|---|---|

Moving Parts | None | Yes |

Switching Speed | Very Fast | Slower |

Wear and Tear | Minimal | High |

Lifespan | Long | Shorter |

Common Failures | Overheating, voltage | Contact wear, dirt |

Note: Devices with fewer moving parts, like transistors, usually last longer and work better in tough places.

Mechanical Wear

Moving Parts in Relays

Mechanical relays have many parts that move to open and close circuits. Every time a relay works, these parts move and touch. This movement causes the parts to wear out over time. The main moving parts are the armature, reset spring, moving contact, and fixed contact. The table below explains what each part does and how it can wear out:

Mechanical Component | Role and Effect on Relay Degradation |

|---|---|

Armature | Moves when the coil gets power. It changes the contacts. Moving a lot makes it wear out. |

Reset Spring | Pushes the armature back to its place. It can get weak or break after many uses. |

Moving Contact | Opens or closes the circuit. Using it a lot wears it down and makes it work less well. |

Fixed Contact | Stays still but gets worn from sparks and movement. Heavy use can make it erode or stick. |

Mechanical wear is a big reason relays stop working. When the armature moves, it can make the contacts spark. This happens more with high current. Sparks can melt or stick the contacts together. This makes the relay stop working. The reset spring can also get weak. If this happens, the relay may not go back to its resting spot.

Relays have two main lifespans: mechanical life and full load life. Mechanical life is how many times a relay can switch with light loads before wearing out. Full load life is shorter. It counts how many times a relay can switch with heavy loads before the contacts stick or wear away. Switching while current flows, called hot switching, damages contacts faster. The clicking sound you hear is the parts moving inside.

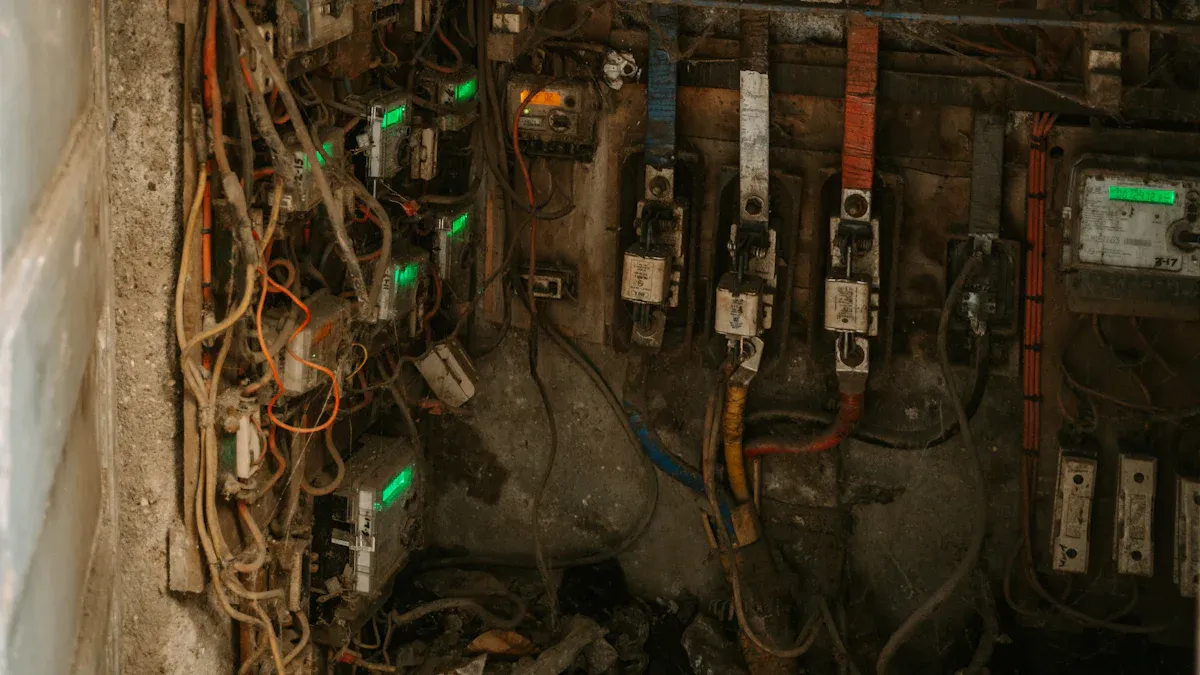

Studies show relays often fail from contact oxidation, coil burnouts, and broken parts. Dust, shaking, and wet air can make these problems worse. Stuck contacts and bad factory work also make relays less reliable. These problems mean relays are not good for places that need high reliability.

Solid-State Advantage

Transistors and solid-state relays do not have moving parts. This gives them a big advantage over mechanical relays. With no moving parts, there is no wear. Devices like MOSFET relays last longer because they do not have contact erosion, spring problems, or sparks. They also work quietly, which is good for quiet places.

Solid-state relays use electronic switches like transistors to control circuits. These switches turn on and off by moving electrons, not metal. This lets them switch faster and more often than relays with moving parts. They also handle shock and shaking better. This makes them great for cars, factories, and space tools.

Studies show solid-state technology avoids problems from moving parts. In advanced factories, solid-state methods stop heat damage and wear by using deformation instead of melting. This makes strong bonds without cracks or stress. Devices last longer this way.

Many industries use solid-state relays for these reasons. You can find them in cars, electronics, and factories. They may cost more at first and need special design, but they last longer and work better. In places like airplanes and space, where things cannot fail, engineers pick solid-state relays for their great performance and strength.

Devices with no moving parts, like transistors, last longer, switch faster, and are more reliable. This is why they are used in modern electronics where good performance and trust matter most.

Switching Speed

Why Transistors Are Faster

Transistors can switch signals much faster than mechanical relays. This is because transistors are solid-state devices. They use electrons to switch, not moving metal parts. Relays need metal parts to move, which takes more time. The speed difference is very big:

Mechanical relays need about one thousandth of a second (1 ms) to switch.

This is much slower than vacuum tubes, which came before transistors.

Transistors switch even faster than vacuum tubes. Their switching is so quick that most circuits do not notice any wait.

Engineers use tests to see how fast transistors can switch. Some tests are called double pulse testing (DPT) and the MADTHOR system. These tests show how transistors work in real life. Wide bandgap transistors, like gallium nitride (GaN) and silicon carbide (SiC), are much faster than old silicon ones. The MADTHOR system uses many tests to check speed and how the device works over time. It also checks how heat and use change how well it works.

SiC MOSFETs can switch very fast in tests. They have high rates of change for current and voltage, called dI/dt and dV/dt. Sometimes, this fast switching makes ringing and overshoot in the circuit. Engineers design special ways to stop these problems and keep switching safe.

In digital circuits, switching speed is measured by rise time, fall time, and propagation delay. Rise time is how long it takes for the output to go from 10% to 90%. Fall time is the opposite. Propagation delay is the time between input and output changes. By making transistors with less unwanted capacitance and better materials, engineers make these times even shorter.

Impact on Reliability

Faster switching does more than just make things quick. It also helps the system last longer. Devices that switch fast have less stress and wear. The table below shows how fast switching helps reliability:

Evidence Aspect | Description | Implication for Reliability and Faster Switching |

|---|---|---|

Switching Speed | OTS device switches in less than 10 ns because there are no atomic changes. | Fast switching lowers delay and stress, making the device more stable. |

Threshold Voltage Stability | Vth changes very little between 10 ns and 10 μs pulses. | Steady operation over time means reliable switching. |

Endurance | Works well after up to 10^12 switches with little wear. | High endurance shows long-term reliability with fast switching. |

Drift Value | Drift is 18 mV/dec, which is below the 20 mV/dec limit. | Low drift keeps the device working well over time. |

Gate Delay in Series Operation | Gate delay is under 20 ns when OTS device is with a transistor in series. | Shows good and reliable switching in real circuits. |

Improved Transistor Performance | SS is less than 20 mV/dec and ION/IOFF is more than 10^5 with steady endurance up to 10^8 cycles. | Better transistor performance and energy use because of OTS device. |

Transistors can switch on and off billions or trillions of times without breaking. This means less fixing and fewer failures. Mechanical relays are slower and have moving parts, so they cannot last as long. In most electronics today, transistors are faster and more reliable than relays. Their speed and solid-state design help devices last longer and work better, even in hard places.

Lifespan

Contact Wear in Relays

Mechanical relays use contacts to open and close circuits. When a relay switches, the contacts touch and pull apart. This makes friction and sometimes small sparks. Over time, this wears down the contacts. Engineers found that wear can start after only a few uses. How fast the contacts move matters too. If they move slowly, more sparks happen and damage the surface faster.

Many things change how fast relay contacts wear out. These include how fast they switch, how hard the contacts press together, the heat, and what metal is used. For example, silver-impregnated graphite contacts get rough and form thin layers after lots of use. Scientists use special tools to look at these changes. As contacts wear, their resistance goes up. This can make the relay stop working.

Tests show that even good materials cannot stop wear. Models use math to guess how long a relay will last. Simple models do not work well because wear is complicated. Relay contacts can turn colors and get pits after a few thousand uses. Dust, wet air, and heat make wear happen faster. Good setup and regular checks help, but cannot stop wear.

The table below shows how long different relays last and what affects them:

Device Type | Typical Lifespan (Switching Cycles) | Key Factors Affecting Lifespan |

|---|---|---|

Mechanical Relays | Hundreds of thousands to over 10 million | Mechanical wear, contact degradation, load type, switching frequency, environment, maintenance |

Electromechanical Relays (EMRs) | Hundreds of thousands to a few million | Mechanical wear on contacts and armatures, maintenance can extend life |

Reed Relays | Tens of millions | Fast switching, application-dependent, low power consumption |

Latching Relays | Millions to tens of millions | Energy-efficient, less wear in low-duty applications |

Note: Things like heat, wet air, and dust can make relays wear out faster by causing rust or blocking moving parts.

Longevity of Transistors

Transistors work with no moving parts. They use electrons to turn circuits on and off. Because of this, there is no friction or sparks. This means transistors can switch billions or trillions of times without wearing out. Their life depends on staying within safe voltage, current, and heat levels.

Solid-state relays use transistors and last much longer than mechanical relays. They can handle tens of millions of cycles or more. Since they do not have touching contacts, they resist shaking, bumps, and electrical noise. Engineers pick transistors for things that switch a lot, like power converters and computers.

Mechanical relays fail when contacts wear out, but transistors keep working if they do not get too hot or overloaded. This is why transistors are chosen for devices that need to last a long time.

Transistors are very strong and reliable in modern electronics. Their long life and toughness make them important for devices that need to work well for a long time.

Power and Size

Power Consumption

Transistors and mechanical relays use power in different ways. Transistors need very little energy to turn on or off. The control pin of a transistor uses only 2 to 4 milliamps. This is a small amount of current. It does not add much to the device’s total power use. Mechanical relays need more power because they use a coil to move contacts. A relay coil usually takes about 66 to 75 milliamps with 5 volts. This means the relay uses about 0.36 watts each time it is on.

Engineers use a trick called pulse-width modulation, or PWM, to save power with relays. PWM turns the relay coil on and off very fast. This lowers the average current to about 23 milliamps. The power drops to about 0.058 watts. PWM can save up to 84% of the power compared to always-on relays. But even with PWM, relays still use more power than transistors.

Parameter | Condition | Measurement | Notes |

|---|---|---|---|

Relay coil current | Direct 5V drive | 66 mA | Close to datasheet value (71.4 mA) |

Relay coil power consumption | Direct 5V drive | 0.36 W (360 mW) | 5V × 0.066A |

Relay coil current | PWM at 51% duty cycle | 23 mA | Voltage about 2.55 V |

Relay coil power consumption | PWM at 51% duty cycle | 0.058 W (58 mW) | 2.55V × 0.023A |

Power reduction | PWM vs direct drive | 84% | Significant energy saving |

Transistor systems help phones, laptops, and IoT gadgets save energy. Many of these devices wait in standby mode for a signal. Their small size and low power needs help them last longer. In big networks like data centers and cell towers, power use depends on the load and technology. For example, 5G networks use sleep modes to save energy. This also helps parts last longer by making less heat.

Devices that use less power make less heat and stress. This helps them last longer and work better.

Miniaturization

Transistors have made electronic devices much smaller. They are tiny compared to mechanical relays. This lets engineers put millions or billions of transistors on one chip. Smaller parts mean lighter and thinner devices.

Making things smaller has helped computers and phones get better for over 50 years. As transistors shrink, devices get faster and use less energy. Engineers now use new designs like gate-all-around transistors and two-dimensional materials. These help make transistors even smaller and more efficient. This allows for:

More transistors on chips, so computers and phones are stronger.

Lower energy use, so batteries last longer.

Better control of signals, which means fewer mistakes and faster speed.

Improved reliability, since smaller devices have fewer moving parts.

Researchers now stack transistors in three layers to keep shrinking device size. This 3D way makes chips faster and saves more energy than old flat designs. Even as parts get very small, new materials and designs help keep electronics tiny and powerful.

Making things smaller lets engineers build tiny, reliable, and energy-saving devices. Transistors make this possible. Mechanical relays are too big for most new gadgets.

Environmental Factors

Vibration and Dust

Vibration and dust can hurt electronic parts. Mechanical relays have moving parts that can shake loose. Strong shaking can make these parts wear out or break. If dust gets inside, it can stop the relay from working. Dust can pile up on contacts and block electricity. This can cause the relay to fail or send wrong signals.

Transistors do not have moving parts. They can handle shaking much better. Dust does not bother them much because they are sealed. Their surfaces are protected from dirt. This makes transistors a better pick for places with lots of shaking or dust, like cars or factories.

Engineers use tests to see if parts survive in tough places. These tests include:

Ingress Protection (IP) testing checks if dust or water gets inside.

Vibration testing shakes the part to see if it stays together.

Salt spray and corrosion tests check if the part lasts in salty air.

Temperature and humidity cycling tests show if the part works in changing weather.

Mechanical shock tests drop or hit the part to check its strength.

Environmental Test Type | Purpose / Demonstrated Resilience | Relevant Standards / Capabilities |

|---|---|---|

Ingress Protection (IP) | Checks dust and water resistance | ISO 20653 / IEC 60529 |

Vibration Testing | Tests durability during shaking or transport | IEC 60068-2-6, ISO 16750-3 |

Salt Spray / Corrosion Testing | Measures resistance to salty air | ASTM B117, IEC 60068-2-11 |

Temperature & Humidity Cycling | Tests function in changing weather | IEC 60068 series, ISO 16750-4 |

Mechanical Shock | Checks response to sudden hits | IEC 60068-2-27 |

Mechanical relays must pass tests like IEC 60255-21-3 for shock and vibration. If dust gets inside, it can lower insulation and cause shorts. The kind of dust and how wet it is can make things worse. Transistors are sealed, so they avoid most of these problems.

Tip: Devices in dusty or shaky places work better and last longer with transistors instead of mechanical relays.

Temperature Effects

Temperature changes can also affect how parts work. Mechanical relays may stop working if it gets too hot or cold. Their metal parts can get bigger or smaller. This can change how the contacts touch. It can cause missed signals or stuck contacts.

Transistors can have trouble with heat too. If they get too hot, they may leak current or break. But engineers design transistors to handle many temperatures. They use special materials and cooling to keep them safe.

Some new relays, called nanoelectromechanical (NEM) relays, work well in high heat. These relays do not leak current when off. Their design stops them from snapping shut by mistake. Tests show NEM relays can work over 40 cycles at 200 °C with no problems. Using contact materials like chromium-gold helps them stay stable when hot.

Note: Both transistors and relays need to stay in their safe temperature range. Transistors usually handle heat better, but special relays can work in very hot places if needed.

Transistors Are Faster and More Reliable Than Mechanical Relays

No Contact Bounce

Mechanical relays have metal contacts that touch to switch circuits. When the contacts close, they can bounce up and down. This bounce makes the circuit turn on and off quickly. Devices might see this as noise or wrong signals. Contact bounce can make relays wear out faster and cause mistakes.

Transistors do not have moving contacts. They use electric fields to switch on and off. Because of this, there is no contact bounce. Circuits with transistors get clear, sharp signals every time. No bounce helps devices work better and last longer. Engineers know transistors are faster and more reliable because they do not have this problem.

Tip: No contact bounce means less damage and fewer errors in electronics.

High Cycling Frequency

Mechanical relays can only switch a certain number of times before wearing out. Their moving parts need time to open and close. If they switch too fast, the contacts can get hot or stick. Most relays cannot handle more than a few thousand switches each hour.

Transistors can switch millions or billions of times every second. They do not wait for parts to move. This high speed makes them great for computers and phones. Devices that need to switch quickly use transistors for better results. In these cases, transistors are faster and more reliable than relays.

The table below shows how often each can switch:

Device Type | Typical Max Switching Rate |

|---|---|

Mechanical Relay | 10–1,000 cycles per second |

Transistor | 1,000,000+ cycles per second |

Note: High switching speed means less waiting and longer life for electronics.

Solid-State Reliability

Transistors are made from solid materials and have no moving parts. This makes them much more reliable. Mechanical relays can break if contacts wear out, springs snap, or dust gets inside. Every moving part can fail.

Transistors can handle shaking, bumps, and dirt. They work well in cars, factories, and space tools. Their solid-state design lets them keep working after millions of switches. Engineers trust transistors for important jobs because they know transistors are faster and more reliable than relays.

Solid-state devices last longer.

They need less fixing.

They work better in rough places.

Devices with transistors often work for years with no trouble. This is why transistors are faster and more reliable than mechanical relays in most electronics today.

Limitations and Misconceptions

When Relays Are Preferred

Transistors have many good points, but relays are still needed sometimes. Engineers pick relays when a circuit must keep control and power sides apart. Relays use a coil and contacts, so the control side never touches the power side. This keeps sensitive electronics safe from high voltages.

Some devices need to switch both AC and DC power. Mechanical relays can handle both, but most transistors work best with DC. Relays are also good for switching many lines at once. For example, one relay can turn on several lights or motors with one signal.

Relays can handle sudden jumps in voltage or current better than many transistors. Sometimes, relays survive power surges that would break a transistor. This makes relays useful in power grids, big machines, and cars.

Note: Relays are often best for simple on-off jobs in high-power circuits, especially when safety and keeping circuits apart is important.

High Voltage and Current Cases

Transistors work well in most electronics, but they have limits. When a circuit needs to switch very high voltage or big currents, relays often do better. Some relays can handle thousands of volts or hundreds of amps. Transistors can switch high power, but they need special designs and cooling to stop overheating.

Mechanical relays do not get as hot as transistors in these cases. Their contacts can take short bursts of high current, like when starting a big motor. If something goes wrong, a relay can break the circuit to protect it.

The table below shows how transistors and relays compare for fast switching and high power:

Technical Aspect | Transistors (MOSFETs in SSRs) | Traditional Electromechanical Relays |

|---|---|---|

Mechanical Parts | None; solid-state operation allows very fast switching | Have mechanical contacts that physically move |

Switching Speed | Extremely fast due to electronic control | Slower due to mechanical movement |

Arcing During Switching | None; voltage-free switching eliminates arcing | Arcing occurs, causing contact wear and potential failure |

Longevity | Can operate for hundreds of millions of hours without wear | Limited by mechanical wear and contact degradation |

Current Control | Efficient control of large currents with small gate voltages | Less precise and slower response |

Application Suitability | Ideal for rapid, frequent switching (e.g., robotic automation, high-speed data processing) | Less suitable for rapid switching due to mechanical delay |

Electrical Isolation | Provides isolation between control and power circuits | Typically provides less isolation |

Transistors, like MOSFETs in solid-state relays, are great for fast switching and long life. But relays are still good for switching very high voltages or currents, and for strong electrical isolation in tough places.

Tip: Engineers should pick the right part for the job. Transistors are best for fast, often switching and low to medium power. Relays are better for high power, high voltage, or when strong isolation is needed.

Transistors work faster and last longer than mechanical relays. They do not have moving parts, so they switch on and off quickly. This makes them more reliable. Tests show that devices like the Atmel Attiny85 microcontroller can keep running for over 1200 hours without breaking, even when stressed. Transistors also handle dust, shaking, and heat better than relays. Most engineers pick transistors for important systems that need to be fast and dependable. But relays are still better when you need to switch high voltage or keep circuits apart. It is important to pick the right part for each project to get the best results.

FAQ

What makes transistors more reliable than mechanical relays?

Transistors have no moving parts. They do not wear out from use. They switch faster and last longer. Engineers trust them for important jobs in electronics.

Can mechanical relays work in harsh environments?

Mechanical relays can fail in dusty or shaky places. Dust can block contacts. Vibration can break moving parts. Transistors handle these conditions better.

Why do relays sometimes make a clicking sound?

Relays use a coil to move metal contacts. When the contacts move, they make a clicking noise. Transistors do not make this sound because they have no moving parts.

Are transistors always the best choice for every circuit?

Transistors work well for most jobs. Relays still work better for switching high voltage or current. Relays also provide strong electrical isolation.

How long can a transistor last in a device?

A transistor can last for billions or even trillions of switches. It stays reliable if it does not get too hot or overloaded.

Do relays or transistors use more power?

Relays use more power because their coils need energy to move contacts. Transistors use much less power. This helps devices save energy and last longer.

Can a relay switch both AC and DC power?

Yes, a relay can switch both AC and DC power. Most transistors work best with DC. Relays are often used when both types of power need switching.

What is contact bounce, and why is it a problem?

Contact bounce happens when relay contacts touch and bounce apart quickly. This can cause errors in circuits. Transistors do not have contact bounce, so they give cleaner signals.

See Also

Understanding How Transistors Function As Amplifiers And Switches

The Importance Of Force Sensitive Resistors In Modern Technology

Comparing IGBT And MOSFET Efficiency In High Power Devices

How To Choose The Right Relays For Automotive Applications

Deciding Between Electronic And Magnetic Ballasts For Your Setup