Exploring Thyristor Functionality in Power Electronics

A thyristor is a four-layer power semiconductor device with a PNPN structure, and understanding the thyristor working principle is essential for its application. It plays a vital role in high-power applications by enabling efficient electrical power control. You can find thyristors in both AC and DC systems, where they regulate power flow, convert energy, and protect equipment. For instance, they manage motor speeds, convert AC to DC, and safeguard devices from voltage spikes.

The global fast thyristor market, valued at USD 1.5 billion in 2023, is projected to grow to USD 2.8 billion by 2032, driven by renewable energy adoption and electric vehicle advancements. Asia Pacific leads this growth due to its strong electronics manufacturing base and investments in industrial and renewable sectors. These trends highlight the increasing demand for thyristors in modern power systems, emphasizing the importance of understanding the thyristor working principle for future innovations.

Key Takeaways

Thyristors help control powerful electrical systems and manage energy well.

Their four-layer PNPN design lets them handle high voltage and current.

Types like SCRs, GTOs, and Triacs work for different tasks in circuits.

A small gate current starts them, controlling power flow in circuits.

They turn off using natural or forced methods in AC and DC systems.

Thyristors improve renewable energy by helping solar and wind systems work better.

Their small size and efficiency save space and lower material costs.

New materials and tech make thyristors better for smart energy systems.

What is a Thyristor?

Structure and Components

Layers of a thyristor (PNPN structure)

A thyristor is a four-layer semiconductor device with alternating P-type and N-type materials, forming a PNPN structure. This arrangement creates three PN junctions (J1, J2, and J3), which determine how the device conducts electricity. The layers work together to control the flow of current, making thyristors essential in power electronic circuits.

The table below highlights the technical details of a thyristor's structure and operation:

Characteristic | Description |

|---|---|

Structure | Four-layer semiconductor device with alternating P-type and N-type materials (P-N-P-N). |

Modes of Operation | 1. Reverse blocking mode: Blocks current when reverse biased. |

Junctions | Three PN junctions (J1, J2, J3) that determine conduction based on their biasing conditions. |

Triggering | Requires a gate current to switch from off to on state, continuing to conduct until holding current is reached. |

Applications | Used in power control, motor speed control, and light dimmers due to their ability to handle large power supplies. |

This layered structure allows thyristors to handle high voltages and currents efficiently, making them ideal for applications like rectifiers and motor control.

Terminals: Anode, Cathode, and Gate

A thyristor has three terminals: the Anode (A), Cathode (K), and Gate (G). The Anode connects to the outer P-layer, while the Cathode connects to the outer N-layer. The Gate terminal, located near the Anode, plays a crucial role in triggering the thyristor. When you apply a small current to the Gate, it activates the device, allowing current to flow between the Anode and Cathode. This design ensures precise control over power flow in power electronic circuits.

Basic Characteristics

Unidirectional current flow

Thyristors allow current to flow in only one direction, from the Anode to the Cathode. This unidirectional behavior makes them similar to diodes but with added control through the Gate terminal. Once triggered, the thyristor remains in the "on" state until the current drops below a specific holding value. This characteristic is particularly useful in rectifiers, where you need to convert alternating current (AC) to direct current (DC).

Voltage and current ratings

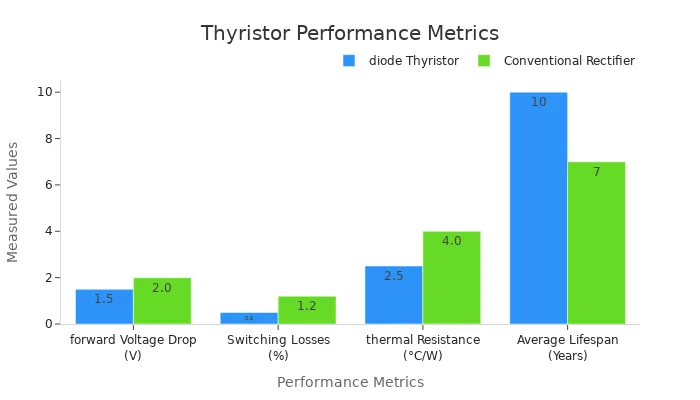

Thyristors are designed to handle high voltages and currents, making them suitable for demanding applications. For example, they can withstand forward and reverse voltages of up to 6,500V, which is critical for high-voltage circuit breakers and current source inverters. The table below compares the performance metrics of thyristors with conventional rectifiers:

Metric | Thyristor | Conventional Rectifier |

|---|---|---|

Forward Voltage Drop (V) | 1.5 | 2.0 |

Switching Losses (%) | 0.5 | 1.2 |

Thermal Resistance (°C/W) | 2.5 | 4.0 |

Average Lifespan (Years) | 10 | 7 |

These metrics highlight the efficiency and durability of thyristors, making them a preferred choice in power electronic circuits.

Types of Thyristors

Understanding the different types of thyristors helps you choose the right one for your application. Each type has unique characteristics and is suited for specific tasks in power electronics. Let’s explore three common types of thyristors.

Silicon-Controlled Rectifier (SCR)

The silicon-controlled rectifier is the most widely used type of thyristor. It consists of a PNPN structure and operates as a switch. When you apply a small current to its gate terminal, the SCR allows current to flow from the anode to the cathode. This makes it ideal for high-power switching applications. Once triggered, it remains in the "on" state until the current drops below the holding value.

SCRs are highly efficient and durable. They consume less power and operate at high switching frequencies. These attributes make them essential in rectification operations and switching functions. For example, SCRs are commonly used in industrial motor control systems to regulate speed and torque. They also play a critical role in renewable energy systems, where they manage power distribution and ensure efficient energy conversion.

Category | Details |

|---|---|

Strengths | High efficiency, durable performance, low power consumption. |

Weaknesses | High cost, low switching speed. |

Opportunities | Rising demand in automotive and industrial applications. |

Threats | High competition from other power controllers, raw material volatility. |

Gate Turn-Off Thyristor (GTO)

The gate turn-off thyristor offers a significant advantage over the SCR. Unlike the SCR, which requires the current to drop below the holding value to turn off, the GTO can be turned off by applying a negative signal to its gate terminal. This feature gives you greater control over the device, especially in dynamic power control applications.

GTOs are commonly used in inverters and DC-DC converters. They are particularly effective in systems with resistive or inductive loads. Experimental studies show that GTOs perform well under varying circuit conditions. For instance, during the turn-off cycle, the removal of charge carriers ensures precise control over power flow. This makes GTOs a preferred choice in applications requiring rapid switching and high efficiency.

Key Features of GTOs:

Can be turned off using a gate signal.

Suitable for dynamic power control in resistive and inductive circuits.

Widely used in inverters and converters.

Triac

The triac is a versatile thyristor that conducts current in both directions. Essentially, it combines two SCRs in parallel, allowing it to control AC power efficiently. You can use a triac in applications like light dimmers, motor speed controllers, and AC power regulators. Its bidirectional conduction capability simplifies circuit design and reduces component count.

Triacs are energy-efficient and reliable. They are particularly useful in household and industrial applications where precise control of AC power is required. For example, a triac-based light dimmer lets you adjust the brightness of a lamp by controlling the amount of power delivered to it. Similarly, triacs are used in motor speed controllers to regulate the speed of fans and pumps.

Advantages of Triacs:

Bidirectional conduction simplifies circuit design.

Energy-efficient and versatile for AC power control.

Commonly used in light dimmers and motor speed controllers.

Type of Thyristor | Description | Applications |

|---|---|---|

Silicon-Controlled Rectifier (SCR) | Most commonly used thyristor, conducts after receiving a trigger current. | Rectification operations, switching functions. |

Gate Turn-Off Thyristor (GTO) | Can be turned off with a negative gate signal. | Inverters, DC-DC converters. |

Triode for Alternating Current (TRIAC) | Conducts in both directions, consists of two SCRs in parallel. | AC power control, light dimmers, motor speed controllers. |

By understanding these types of thyristors, you can select the one that best suits your needs. Whether you need precise control, bidirectional conduction, or high efficiency, there is a thyristor designed for your application.

Reverse Conducting Thyristor (RCT)

The Reverse Conducting Thyristor (RCT) combines a silicon-controlled rectifier (SCR) with a reverse diode. This integration allows the device to conduct current in the reverse direction, making it highly efficient in managing reverse currents. You can use RCTs in applications where reverse voltage transients and loop inductance need to be minimized. These features make RCTs ideal for high-power circuits that require precise control over reverse currents.

RCTs are particularly useful in motor drives and power converters. Their ability to handle reverse currents efficiently reduces energy losses and enhances system reliability. For example, in motor drive systems, RCTs ensure smooth operation by mitigating voltage spikes during switching. This capability not only improves performance but also extends the lifespan of the equipment.

By integrating an SCR and a reverse diode, RCTs significantly reduce undesired loop inductance and manage reverse voltage transients effectively. This makes them a preferred choice for high-power applications.

Light-Activated Thyristor (LAT)

The Light-Activated Thyristor (LAT) operates using light instead of an electrical signal to trigger conduction. This unique feature allows LATs to function in environments with high electrical noise or where electrical isolation is critical. You will often find LATs in high-voltage direct current (HVDC) transmission systems, reactive power compensators, and high-power pulse generators.

LATs offer several advantages over traditional thyristors. Their activation by light ensures complete electrical isolation between the control circuit and the thyristor. This isolation enhances safety and reliability, especially in high-voltage applications. Additionally, LATs perform well in specialized switching scenarios, making them indispensable in advanced power systems.

Feature | Benefit |

|---|---|

Activation by light | Enables operation in high-voltage applications and noisy environments. |

Electrical isolation | Provides complete separation between the light source and the device. |

Applications | Used in HVDC systems, reactive power compensators, and pulse generators. |

Programmable Unijunction Thyristor (PUT)

The Programmable Unijunction Thyristor (PUT) is a versatile device used in oscillator circuits and timing applications. Unlike other types of thyristors, PUTs allow you to program their triggering voltage, giving you greater control over their operation. This flexibility makes PUTs suitable for a wide range of electronic applications.

PUTs are commonly used in relaxation oscillator circuits. These circuits generate periodic waveforms, which are essential in timing and control systems. Studies have shown that PUTs perform reliably under various conditions, including high temperatures and radiation environments. This reliability makes them a popular choice in industrial and aerospace applications.

For example, in a relaxation oscillator configuration, a PUT can produce stable and precise output waveforms. This capability is crucial for applications requiring accurate timing, such as clock generators and signal modulators. The ability to operate under extreme conditions further enhances the versatility of PUTs.

PUTs excel in oscillator circuits, offering stable performance even in challenging environments. Their programmability and reliability make them a valuable addition to modern electronic systems.

Thyristor Working Principle

Triggering Mechanism

Role of the gate terminal

The gate terminal plays a crucial role in the thyristor working principle. It acts as the control point for turning the thyristor on. When you apply a small current to the gate terminal, it initiates the conduction process. This current creates a chain reaction within the PNPN layers, allowing the thyristor to conduct electricity between the anode and cathode. Without this gate signal, the thyristor remains in its off state, blocking current flow. This precise control makes thyristors essential in power control circuits.

Voltage and current requirements for triggering

To turn on a thyristor, specific voltage and current conditions must be met. The device becomes forward-biased when the anode is positive relative to the cathode. At this point, a small pulse of current applied to the gate terminal triggers conduction. The table below summarizes these requirements:

Aspect | Description |

|---|---|

Triggering Mechanism | Thyristors can be turned on by applying a gate signal during the positive half-cycle of AC. |

Voltage Requirement | The thyristor is forward biased when the anode is positive, allowing it to be triggered on. |

Current Requirement | A small trigger pulse of current is needed at the gate terminal to initiate conduction. |

Natural Commutation | In AC circuits, natural commutation allows the thyristor to turn off at the zero crossing point. |

Holding Current (IH) | The thyristor remains conducting until the anode current drops below the holding current. |

Once triggered, the thyristor remains on until the current through it falls below the holding current. This behavior ensures stable operation in power control circuits.

💡 Tip: The gate pulse duration is typically a few microseconds, but it must be sufficient to fully activate the thyristor.

Conduction Phase

Latching and holding current

The conduction phase of a thyristor begins once it is latched on. A single pulse of positive current at the gate terminal is enough to latch the device. After this, the anode current must exceed the holding current to maintain conduction. If the current drops below this level, the thyristor turns off. This characteristic ensures that the device remains stable during operation.

Key points about conduction:

Latching occurs with a single gate pulse.

The anode current must stay above the holding current for continuous operation.

Thyristors are ideal for applications requiring steady current flow.

Continuous current flow after triggering

Once the thyristor is triggered, it allows continuous current flow between the anode and cathode. This flow persists as long as the anode current remains above the holding current. The voltage drop across the thyristor during conduction is minimal, typically around 1.0V. This efficiency makes thyristors a preferred choice in power control circuits.

Turning Off a Thyristor

Natural commutation

Natural commutation occurs in AC circuits where the current naturally drops to zero at the end of each half-cycle. This zero-crossing point allows the thyristor to turn off without external intervention. For example, in an AC rectifier circuit, the alternating nature of the current ensures that the thyristor turns off automatically at the appropriate time.

Forced commutation

In DC circuits, where the current does not naturally fall to zero, forced commutation is necessary. This method involves using external components to reduce the anode current below the holding current. Forced commutation is essential in applications like DC motor drives, where precise control over the thyristor turn-off process is required.

Natural commutation relies on the reversal of voltage in AC circuits, while forced commutation requires external means to interrupt the current. These methods highlight the versatility of thyristors in different power control circuits.

Applications of Thyristors in Power Electronics

Thyristors in power electronics play a pivotal role in various applications, enabling efficient power control and conversion. Their ability to handle high voltages and currents makes them indispensable in motor control, power conversion, and renewable energy systems.

Motor Control

Speed control in industrial motors

Thyristors are widely used in industrial motor control systems to regulate speed. By adjusting the voltage supplied to the motor, you can achieve precise speed control, which is essential in manufacturing processes. Thyristor-based controllers ensure smooth operation and reduce energy consumption. For instance, in split-phase and three-phase induction motor drives, thyristors provide efficient soft starting, minimizing mechanical stress and extending motor lifespan.

Key benefits of thyristor-based motor control:

Smooth acceleration and deceleration.

Reduced energy consumption during operation.

Enhanced motor durability due to minimized wear and tear.

Soft starters for AC motors

Soft starters using thyristors limit the inrush current during motor startup. This feature prevents electrical and mechanical stress on the motor and connected equipment. Studies comparing soft starters based on thyristors and IGBTs show that thyristor-based systems excel in performance. For example:

A 3-phase AC voltage controller with thyristors achieves smooth motor startup.

The addition of a shunt active filter reduces harmonic distortion and reactive power, improving overall efficiency.

These characteristics make thyristors ideal for soft-start applications in industries requiring reliable motor operation.

Power Conversion

AC to DC rectification

Thyristors serve as efficient rectifiers in high-power systems, converting AC to DC with minimal energy loss. Their low forward voltage drop and excellent thermal performance ensure reliable operation. The table below highlights key metrics validating their efficiency:

Metric | Description |

|---|---|

Forward Voltage Drop | Reduces energy loss during rectification. |

Switching Losses | Minimizes energy wastage during operation. |

Thermal Performance | Ensures longevity and reliability in high-power systems. |

By using thyristors, you can achieve efficient energy conversion, lower operational costs, and reduced carbon emissions.

DC to AC inverters

Thyristors are also crucial in DC to AC inverters, which are used in power converters. These devices ensure efficient energy usage by minimizing losses during conversion. Thyristor-based inverters are particularly effective in industrial applications, where they reduce energy consumption and improve system reliability. This efficiency not only lowers costs but also supports sustainability by reducing greenhouse gas emissions.

Renewable Energy Systems

Solar inverters

In solar power systems, thyristors enhance the efficiency and reliability of inverters. They convert DC generated by solar panels into AC for grid use. Thyristor-based inverters optimize energy usage, resulting in lower operational costs and reduced maintenance. Their robust design ensures minimal downtime, making them a preferred choice in renewable energy installations.

Wind turbine control

Thyristors play a critical role in wind turbine control systems. They regulate power flow and ensure smooth operation under varying wind conditions. By optimizing energy use, thyristors contribute to decreased operational costs and lower greenhouse gas emissions. Their durability and efficiency make them essential components in modern wind power installations.

Advantage | Description |

|---|---|

Enhanced Reliability | Reduces downtime and improves performance metrics. |

Cost Efficiency | Lowers energy bills and maintenance costs. |

Support for Green Initiatives | Facilitates the transition to renewable energy sources. |

Thyristors in power electronics enable the seamless integration of renewable energy into the grid, supporting global efforts to combat climate change.

Other Applications

Static switches

Static switches are an essential part of modern power systems. Unlike mechanical switches, they use thyristors to control the flow of electricity. This design eliminates moving parts, which significantly improves reliability and efficiency. You can rely on static switches for faster switching times and reduced wear and tear. They also prevent issues like contact bounce, which is common in mechanical switches. These features make static switches ideal for critical applications where precision and durability are crucial.

For example, static switches are widely used in uninterruptible power supply (UPS) systems. In these systems, they ensure a seamless transition between power sources during outages. This capability protects sensitive equipment from damage and ensures continuous operation. Additionally, static switches play a vital role in industrial automation, where they enable precise control of machinery and processes. Their ability to handle high power levels while maintaining efficiency makes them indispensable in these applications.

Thyristors enhance the performance of static switches by providing rapid and reliable switching. Their solid-state nature eliminates the need for mechanical contacts, resulting in smoother operation and longer lifespan. This advantage reduces maintenance costs and improves overall system performance. By integrating thyristors into static switches, you can achieve superior efficiency and reliability in your power systems.

Voltage regulators

Voltage regulators are another critical application of thyristors. These devices maintain a stable output voltage, even when input voltage or load conditions fluctuate. You can use voltage regulators to protect sensitive electronic devices from damage caused by voltage variations. Thyristors play a key role in these systems by adjusting the voltage in real-time to ensure stability.

In industrial settings, voltage regulators are essential for maintaining consistent power supply to equipment. For instance, they prevent voltage drops that could disrupt production lines or damage machinery. In residential applications, voltage regulators safeguard home appliances from power surges. This protection extends the lifespan of your devices and reduces the risk of costly repairs.

Thyristors improve the efficiency of voltage regulators by enabling precise control over voltage levels. Their ability to respond quickly to changes in input voltage ensures stable operation under varying conditions. This feature makes them ideal for applications requiring high reliability and accuracy. Whether you are managing power in an industrial plant or protecting household electronics, thyristor-based voltage regulators provide a dependable solution.

💡 Tip: When selecting a voltage regulator, consider the input voltage range and load requirements to ensure optimal performance.

Advantages of Using Thyristors

High Efficiency

Thyristors are known for their exceptional efficiency in power control and regulation. Their ability to handle high currents and voltages without significant energy loss makes them a preferred choice in demanding applications. For instance, their fast-switching capabilities reduce energy waste and improve process timing. This feature is particularly beneficial in industrial systems where precise power regulation is critical.

The table below highlights the performance features that contribute to the high efficiency of thyristors:

Feature | Benefit |

|---|---|

High Current Rating | Handles increased loads without failure. |

Fast Switching | Reduces energy waste and improves process timing. |

Robust Design | Ensures longevity and dependability. |

Additionally, thyristors maintain robust thermal stability, ensuring consistent performance across a wide temperature range. This reliability makes them ideal for power regulation and conversion in both industrial and renewable energy applications.

💡 Tip: Using thyristors in your systems can significantly enhance energy efficiency while reducing operational costs.

Compact Size

The compact size of thyristors offers a significant advantage in modern power electronic systems. Unlike mechanical switches and relays, thyristors occupy much less space, making them ideal for densely packed circuits. This compactness allows you to design smaller and more efficient devices without compromising performance.

Key benefits of their compact size include:

Efficient use of space in electronic devices.

Enhanced overall efficiency in densely packaged systems.

Simplified integration into modern power electronics applications.

For example, in renewable energy systems like solar inverters, the small size of thyristors enables the design of lightweight and portable units. This feature not only saves space but also reduces material costs, making thyristors a cost-effective solution for high-performance systems.

High Voltage and Current Handling

Thyristors excel in handling high voltages and currents, making them indispensable in power-intensive applications. Their ability to manage forward and reverse voltages of up to 6,500V ensures reliable operation in high-power circuits. This capability simplifies circuit design and reduces overall system costs.

Some technical highlights of thyristors include:

Minimal on-state and off-state losses, enhancing efficiency in power control.

Fast-switching capabilities for rapid on/off control, essential in motor drives and power inverters.

High withstand voltage ratings, ensuring durability in demanding environments.

For instance, thyristors are widely used in industrial motor drives and power converters, where they handle high currents with ease. Their robust design ensures dependable performance, even under extreme conditions, making them a trusted component in critical applications.

🔧 Note: Thyristors' high voltage and current handling capabilities make them a reliable choice for applications requiring robust and efficient power control.

Reliability and Durability

When you choose thyristors for your power systems, you gain access to devices known for their exceptional reliability and durability. These qualities make thyristors a trusted component in industrial and high-power applications. Their robust design ensures consistent performance, even in challenging environments.

Thyristors excel in maintaining reliability over time. Their ability to handle high currents and voltages without failure makes them ideal for critical applications. For example, in industrial motor drives, thyristors operate efficiently under heavy loads, ensuring smooth and uninterrupted performance. This reliability reduces the risk of downtime, saving you both time and money.

Durability is another key strength of thyristors. Their low thermal resistance minimizes overheating, which prolongs their lifespan. This feature is especially important in applications where devices face extreme temperatures or power surges. For instance, in renewable energy systems, thyristors withstand harsh conditions while maintaining optimal performance. Their high surge capability allows them to handle unexpected power spikes, protecting your equipment from damage.

The table below highlights the features that contribute to the reliability and durability of thyristors:

Feature | Benefit |

|---|---|

High Reliability | Ensures consistent performance over time. |

Robust Design | Enhances durability in harsh industrial environments. |

Low Thermal Resistance | Reduces overheating, prolonging device life. |

High Surge Capability | Allows handling of unexpected power spikes. |

These features make thyristors a dependable choice for various applications. Whether you are managing power in industrial systems or renewable energy installations, thyristors deliver long-lasting performance. Their ability to endure harsh conditions and maintain efficiency ensures that your systems run smoothly for years.

By incorporating thyristors into your designs, you can achieve both reliability and durability. These qualities not only enhance the performance of your applications but also reduce maintenance costs. When you invest in thyristors, you invest in a solution built to last.

Future Trends in Thyristor Technology

Advancements in Material Science

Use of silicon carbide (SiC) and gallium nitride (GaN)

Recent advancements in materials science are revolutionizing the power electronics industry. You will find that silicon carbide (SiC) and gallium nitride (GaN) are at the forefront of this transformation. These wide bandgap semiconductors offer significant advantages over traditional silicon. SiC, for instance, is projected to grow at a CAGR of 4.2% in the power electronics market. It provides higher breakdown electric field strength, a wider band gap, and lower thermal expansion. These properties make SiC highly desirable for photovoltaic cell applications, especially in developing countries.

GaN is also gaining traction due to its use in radio frequency equipment and telecommunications. Its application in electric and hybrid vehicles further underscores its importance. These materials enable the development of next-generation rectifiers with higher voltage and temperature ratings. As a result, you can achieve enhanced efficiency in power electronics, which is crucial for modern applications.

Integration with Smart Grids

Thyristors play a pivotal role in the integration of smart grids. They facilitate real-time control and monitoring of power flow, enhancing grid stability and efficiency. In industrial settings, thyristors are ideal due to their high voltage handling capabilities. Their fast switching capabilities improve performance in power regulation and conversion. By incorporating thyristors into smart grids, you can achieve effective power management. This integration ensures that modern electrical networks operate smoothly and efficiently.

Enhanced Performance for Renewable Energy

In the realm of renewable energy, thyristors are indispensable. They enhance the performance of solar inverters and wind turbine control systems. By optimizing energy use, thyristors contribute to decreased operational costs and lower greenhouse gas emissions. Their robust design ensures minimal downtime, making them a preferred choice in renewable energy installations. As you explore renewable energy solutions, consider the role of thyristors in achieving efficient and reliable power conversion.

🌱 Note: Embracing these advancements in thyristor technology can significantly enhance the efficiency and reliability of your power systems.

Miniaturization and Cost Reduction

Advancements in thyristor technology have led to significant miniaturization and cost reductions. These improvements make thyristors more accessible and practical for a wide range of applications. You can now find compact thyristors that deliver the same performance as their larger predecessors, enabling more efficient designs in power electronics.

Benefits of Miniaturization

Miniaturization allows you to integrate thyristors into smaller devices without sacrificing performance. This is especially important in industries like consumer electronics, where space is limited. Smaller thyristors also reduce the overall weight of systems, making them ideal for portable and mobile applications.

Space Efficiency: Miniaturized thyristors save valuable space in circuit designs.

Improved Portability: Lightweight components enhance the mobility of devices.

Enhanced Performance: Despite their size, modern thyristors maintain high voltage and current handling capabilities.

For example, in renewable energy systems, compact thyristors allow you to design smaller inverters and converters. This not only saves space but also reduces material costs, making renewable energy solutions more affordable.

Cost Reduction Strategies

Manufacturers have adopted innovative techniques to lower the production costs of thyristors. These strategies include using advanced materials and streamlining manufacturing processes. As a result, you can now purchase high-performance thyristors at a fraction of their previous cost.

Strategy | Impact on Cost Reduction |

|---|---|

Use of Advanced Materials | Enhances efficiency while reducing material waste. |

Automated Manufacturing | Lowers labor costs and improves production consistency. |

Bulk Production | Reduces unit costs through economies of scale. |

These cost reductions make thyristors more accessible for small businesses and hobbyists. You can now experiment with power electronics without worrying about high expenses.

💡 Tip: When selecting thyristors, consider both size and cost to ensure they meet your project requirements.

Miniaturization and cost reduction have transformed thyristor technology. These advancements allow you to create efficient, affordable, and compact power systems. Whether you are designing for industrial use or personal projects, modern thyristors offer unmatched versatility and value.

Thyristors are vital components in power electronics, offering efficient control for high-power applications. You can use them to regulate motor speeds, convert energy, and integrate renewable systems. Their working principle, based on precise triggering and conduction, ensures reliable operation in demanding environments.

Key trends in thyristor technology include:

Higher voltage and current ratings.

Enhanced switching speeds for faster operation.

Improved thermal management for durability.

Integration with renewable energy systems.

Miniaturization for compact designs.

These advancements highlight thyristors' growing importance in modern power systems and their potential to shape future innovations.

FAQ

What is the main purpose of a thyristor?

A thyristor controls high-power electrical systems by acting as a switch. You can use it to regulate current flow in circuits, making it essential for applications like motor control, power conversion, and renewable energy systems.

How does a thyristor differ from a transistor?

A thyristor is designed for high-power switching and remains on after triggering. A transistor, on the other hand, amplifies signals and requires continuous input to stay active. You’ll find thyristors in power systems and transistors in signal processing.

Can a thyristor handle AC and DC currents?

Yes, thyristors work with both AC and DC currents. In AC systems, they control power flow by switching at specific points in the cycle. In DC systems, they regulate current through precise triggering and commutation techniques.

Why are thyristors used in renewable energy systems?

Thyristors optimize energy conversion in solar inverters and wind turbines. They ensure efficient power flow, reduce energy losses, and enhance system reliability. You’ll find them indispensable in integrating renewable energy into modern grids.

What are the key advantages of using thyristors?

Thyristors offer high efficiency, compact size, and excellent voltage and current handling. They are durable and reliable, making them ideal for industrial, automotive, and renewable energy applications. Their fast-switching capabilities also improve system performance.

How do you turn off a thyristor in a DC circuit?

In DC circuits, you use forced commutation to turn off a thyristor. This method involves external components that reduce the current below the holding value, ensuring the thyristor stops conducting.

Are thyristors suitable for household applications?

Yes, thyristors are used in household devices like light dimmers and fan speed controllers. Their ability to handle AC power efficiently makes them a practical choice for home automation and energy-saving solutions.

What is the lifespan of a thyristor?

Thyristors typically last around 10 years or more, depending on usage and environmental conditions. Proper thermal management and avoiding overloading can extend their lifespan significantly.

💡 Tip: Regular maintenance and monitoring can help you maximize the lifespan of thyristors in your systems.