Key Differences Between Start and Run Capacitors

Electric motors rely on capacitors to function effectively. Start capacitors deliver an initial burst of energy to help the motor overcome inertia and begin rotating. Run capacitors, on the other hand, maintain steady power to ensure smooth and efficient operation. Each type plays a unique role in motor performance. Understanding the differences between start capacitor vs run capacitor helps you choose the right one for your motor and keep it running efficiently.

Key Takeaways

Start capacitors give motors a quick energy boost to start.

Run capacitors keep the motor running with a steady flow.

Using the right capacitor stops motor problems and damage.

Start capacitors turn off when the motor reaches 75% speed.

Run capacitors are needed for machines that run a long time, like HVACs.

Check and test capacitors often to find problems early.

Replace bad capacitors quickly to stop overheating and motor issues.

Follow maker instructions for safe setup and care of capacitors.

What is a Start Capacitor?

Purpose of a Start Capacitor

A start capacitor plays a vital role in the operation of many electric motors, especially single-phase motors. It provides the initial burst of energy required to overcome inertia and get the motor running. When you power on the motor, the start capacitor connects in series with the motor's windings. This connection delivers an extra jolt of power, enabling the motor to begin rotating. Without this component, the motor would struggle to start and might only produce a humming sound.

The start capacitor creates a current-to-voltage lag in the motor's start windings. This lag allows the current to build up, generating the torque needed to move the motor's armature. Once the motor reaches about 75% of its operating speed, a centrifugal switch or relay disconnects the start capacitor. This ensures the capacitor operates only during the startup phase, preventing overheating or damage.

How a Start Capacitor Works

The start capacitor works by temporarily storing electrical energy and releasing it when the motor starts. It connects to the motor's auxiliary winding, creating a phase shift that generates the torque needed to start the motor. This phase shift occurs because the capacitor alters the timing of the current flow, ensuring the motor's magnetic field rotates in the correct direction.

Once the motor reaches its desired speed, the centrifugal switch disengages the start capacitor. This disconnection is crucial because the capacitor is not designed for continuous operation. Its primary function is to provide the necessary torque during startup, after which the motor operates independently.

Design and Construction of Start Capacitors

Start capacitors are designed for short-term use and feature a high capacitance value, typically ranging from 100 to 1600 µF. They are often constructed using non-polarized aluminum electrolytic materials, which allow them to handle the high energy demands of motor startup. These capacitors are usually cylindrical in shape, making them easy to install in motor housings.

The table below highlights some key specifications of start capacitors:

Feature | Description |

|---|---|

Typically ranges from 100 to 1600 µF, higher than run capacitors. | |

Voltage Classifications | Common ratings include 125 V, 165 V, 250 V, and 330 V. |

Purpose and Function | Provides the initial burst of energy to start an electric motor. |

Operational Mechanism | Temporarily connected in series with the motor’s windings during startup. |

Disengagement Mechanism | A centrifugal switch disconnects the capacitor once the motor reaches speed. |

Start capacitors are designed for short operational periods. They provide high torque to ensure the motor starts quickly and efficiently. However, their temporary nature means they must disconnect promptly to avoid damage.

Common Applications of Start Capacitors

Start capacitors play a crucial role in various devices and systems across residential, commercial, and industrial sectors. Their ability to provide the initial torque needed to start motors makes them indispensable in many applications. You’ll find these capacitors in equipment that requires a reliable and powerful startup.

In residential settings, start capacitors are commonly used in household appliances. Devices like air conditioners, refrigerators, washing machines, and fans rely on them to start their motors efficiently. For example, when you turn on your air conditioner, the start capacitor ensures the compressor motor begins running smoothly, delivering cool air to your home.

In commercial environments, start capacitors are essential for HVAC systems and refrigeration units. Office buildings and retail stores often depend on these systems to maintain comfortable temperatures and preserve perishable goods. Electrical equipment in these spaces also uses start capacitors to ensure reliable operation during startup.

Industrial applications demand even more from start capacitors. Heavy machinery, such as pumps, compressors, and conveyor systems, relies on them to handle the high torque requirements during startup. These capacitors also support motors in manufacturing plants, where consistent performance is critical for productivity.

Here’s a breakdown of the most common applications of start capacitors across different sectors:

Sector | Applications |

|---|---|

Residential | Household appliances like air conditioners, refrigerators, washing machines, and fans. |

Commercial | HVAC systems, refrigeration units, and electrical equipment in office buildings and retail stores. |

Industrial | Pumps, compressors, conveyor systems, and heavy machinery. |

Start capacitors are vital in ensuring motors start effectively in these diverse applications. Without them, many of the devices and systems you rely on daily would struggle to function. Their role in providing the necessary power boost during startup makes them a key component in motor-driven equipment.

What is a Run Capacitor?

Purpose of a Run Capacitor

A run capacitor plays a critical role in the operation of single-phase motors. Unlike a start capacitor, which provides an initial burst of energy, a run capacitor ensures continuous operation by maintaining a steady flow of current. It stays connected to the motor throughout its operation, helping to create a consistent rotating magnetic field. This consistency improves the motor's efficiency and reduces heat generation, which extends the motor's lifespan.

Run capacitors are essential for keeping motors running smoothly. They prevent uneven magnetic fields, which can cause vibrations or inefficiencies. By maintaining a stable phase angle between the motor's windings, they optimize performance and reduce energy consumption. You’ll find them in applications where motors need to operate for extended periods, such as HVAC systems, washing machines, and industrial equipment.

How a Run Capacitor Works

The run capacitor works by providing a continuous phase shift to the motor's windings. This phase shift ensures that the motor generates a stable and efficient rotating magnetic field. Unlike a start capacitor, which disconnects after the motor starts, the run capacitor remains active during the entire operation. This ongoing support is vital for maintaining the motor's performance and preventing energy loss.

You can think of the run capacitor as a stabilizer. It ensures that the motor receives a steady supply of current, which keeps it running efficiently. This stability reduces wear and tear on the motor's components, improving its durability. For example, in HVAC systems, the run capacitor helps fan and blower motors distribute air efficiently. In washing machines, it ensures smooth motor operation, reducing mechanical stress and improving energy efficiency.

Here are some key functions of a run capacitor:

It operates continuously, providing stable current and energy.

It maintains a consistent phase angle, which is crucial for efficient motor performance.

It reduces energy consumption and minimizes wear on motor components.

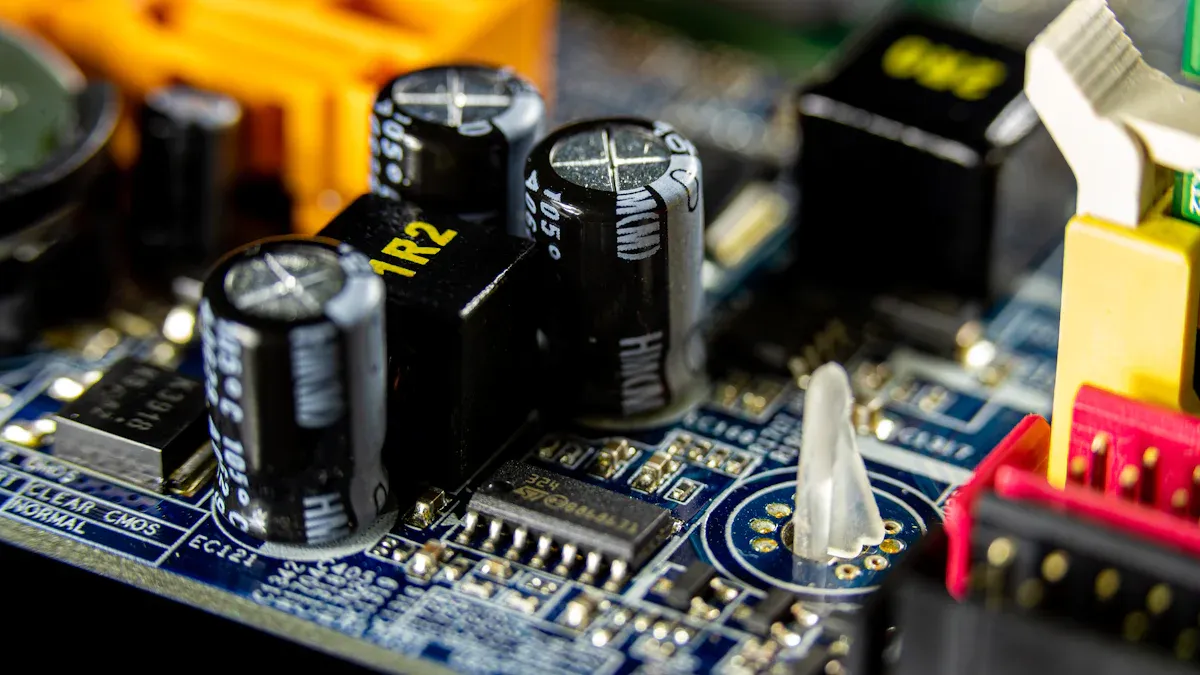

Design and Construction of Run Capacitors

Run capacitors are designed for durability and long-term use. They typically have lower capacitance ratings than start capacitors, ranging from 2.5 to 100 µF. Their voltage ratings are usually 370 or 440 VAC, making them suitable for continuous operation in various motor applications. These capacitors are available in round or oval case styles, with terminal types like ¼" push-on terminals or 2-4 tabs for easy installation.

The table below highlights the technical specifications of run capacitors:

Specification | Details |

|---|---|

Capacitance Ratings | 2.5-100 µF |

Voltage Ratings | 370 or 440 VAC |

Frequency | 50 and 60 Hz rated |

Case Styles | Round or Oval |

Terminal Types | ¼" push-on terminals, 2-4 tabs |

Run capacitors are built to handle the demands of continuous operation. Their robust design ensures they can withstand the heat and stress associated with long-term use. This makes them a reliable choice for applications requiring consistent motor performance.

Common Applications of Run Capacitors

Run capacitors play a vital role in many devices and systems that require motors to operate continuously. You’ll find them in a wide range of residential, commercial, and industrial applications. Their ability to maintain steady motor performance makes them indispensable in ensuring efficiency and reliability.

Residential Applications

In your home, run capacitors are commonly used in appliances that operate for extended periods. For example, air conditioners rely on them to keep the compressor and fan motors running smoothly. Washing machines also use run capacitors to ensure the drum rotates efficiently during wash and spin cycles. Refrigerators depend on them to maintain the consistent operation of their compressor motors, keeping your food fresh. Ceiling fans are another example, where the run capacitor helps maintain a steady airflow.

Commercial Applications

In commercial settings, run capacitors are essential for HVAC systems. These systems regulate temperature and air quality in offices, retail stores, and other public spaces. The run capacitor ensures that blower and fan motors operate efficiently, reducing energy consumption and wear. You’ll also find them in refrigeration units used in grocery stores and restaurants. These units rely on run capacitors to keep their compressors running reliably, preserving perishable goods.

Industrial Applications

Run capacitors are critical in industrial environments where motors power heavy machinery. Conveyor belts, pumps, and compressors all depend on them for consistent performance. For instance, in manufacturing plants, run capacitors help maintain the smooth operation of motors driving production lines. This reliability minimizes downtime and ensures productivity. They also play a key role in agricultural equipment, such as irrigation pumps, where continuous motor operation is crucial.

Tip: If you notice a motor running inefficiently or overheating, the run capacitor might be faulty. Replacing it promptly can restore optimal performance.

Run capacitors are essential in any application where motors need to run for long periods. Their ability to stabilize current flow and improve efficiency makes them a cornerstone of modern motor-driven systems.

Key Differences Between Start and Run Capacitors

Purpose and Role in Motor Operation

Start and run capacitors serve distinct purposes in motor operation. A start capacitor provides the initial energy boost required to overcome inertia and start the motor. It connects temporarily to the motor's windings during startup and disengages once the motor reaches about 75% of its operating speed. This temporary role ensures the motor starts efficiently without overheating or stalling.

In contrast, a run capacitor supports continuous operation by maintaining a steady flow of current throughout the motor's runtime. It remains connected to the motor's windings, creating a stable rotating magnetic field. This stability improves efficiency, reduces energy consumption, and minimizes wear on motor components. You’ll find run capacitors in applications where motors operate for extended periods, such as HVAC systems and industrial machinery.

Here’s a quick comparison of their roles:

Capacitor Type | Function | Application |

|---|---|---|

Start Capacitor | Provides initial burst of energy to start the motor. | Used in single-phase motors and devices requiring high starting torque. |

Run Capacitor | Supports continuous operation of the motor. | Ideal for motors running for long durations. |

Design and Construction Differences

The design and construction of start and run capacitors reflect their specific roles. Start capacitors are typically larger and have higher capacitance values, ranging from 100 to 1600 µF. They are constructed using electrolytic materials, which allow them to handle the high energy demands during motor startup. However, this design limits them to short-term use, as continuous operation would cause overheating.

Run capacitors, on the other hand, are designed for durability and long-term use. They have lower capacitance values, usually between 5 and 100 µF, and are made from metallized film or ceramic materials. These materials ensure the capacitor can withstand the heat and stress of continuous operation. Run capacitors are also more compact, making them suitable for applications where space is limited.

Here’s a detailed comparison of their design features:

Feature | Start Capacitor | Run Capacitor |

|---|---|---|

Purpose | Provides initial burst of energy. | Supports continuous operation. |

Capacitance Value | High (100 to 1600 µF). | Low (5 to 100 µF). |

Materials | Electrolytic. | Metallized film or ceramic. |

Connection | Temporarily connected during startup. | Remains connected during operation. |

Size | Larger, cylindrical design. | Compact, available in round or oval shapes. |

Voltage and Capacitance Ratings

The voltage and capacitance ratings of start and run capacitors differ significantly due to their intended functions. Start capacitors are designed for intermittent duty, with capacitance values ranging from 100 to 1600 µF. These high values enable them to deliver the powerful energy burst needed to start the motor. However, they cannot handle continuous operation and must disconnect after the motor starts.

Run capacitors, in contrast, are built for continuous operation. Their capacitance values are lower, typically between 5 and 100 µF, as they only need to maintain a steady current flow. Run capacitors also have higher voltage ratings, usually 370 or 440 VAC, to ensure reliable performance over long periods.

Key differences in ratings include:

Start capacitors: High capacitance (100 to 1600 µF), designed for short bursts of energy.

Run capacitors: Lower capacitance (5 to 100 µF), suitable for continuous operation.

These differences highlight the importance of selecting the right capacitor for your motor. Using a start capacitor in place of a run capacitor, or vice versa, can lead to motor inefficiency or failure.

Applications and Usage Scenarios

Start and run capacitors play essential roles in various motor-driven systems. Their applications differ based on their unique functions and design characteristics. Understanding these scenarios helps you choose the right capacitor for your specific needs.

Start capacitors are ideal for devices requiring high starting torque. You’ll find them in single-phase motors used in appliances like air conditioners, refrigerators, and washing machines. These capacitors provide the initial energy boost needed to overcome inertia and start the motor. For example, when you turn on an air conditioner, the start capacitor ensures the compressor motor begins running smoothly. Their larger size makes them suitable for applications with more space, such as industrial pumps and compressors.

Run capacitors, on the other hand, are designed for continuous operation. They are commonly used in both single-phase and three-phase motors. These capacitors maintain a steady current flow, ensuring efficient motor performance over extended periods. You’ll see them in HVAC systems, where they keep fan and blower motors running efficiently. Washing machines and refrigerators also rely on run capacitors to ensure smooth and consistent operation. Their compact design makes them ideal for applications where space is limited.

Here’s a quick overview of their applications and design characteristics:

Capacitor Type | Application | Design Characteristics |

|---|---|---|

Start Capacitor | Used in single-phase motors for high starting torque. | Typically larger in size, suitable for applications with more space. |

Run Capacitor | Used in both single-phase and three-phase motors. | Designed for continuous use, ideal for motors running for extended periods. |

By understanding these usage scenarios, you can ensure your motor operates efficiently and reliably. Choosing the correct capacitor type prevents motor failure and extends the lifespan of your equipment.

Comparison Table: Start Capacitor vs Run Capacitor

A side-by-side comparison highlights the key differences between start and run capacitors. This table provides a clear understanding of their unique roles and characteristics:

Feature | Start Capacitor | Run Capacitor |

|---|---|---|

Purpose | Provides an initial burst of energy to start the motor. | Supports continuous operation of the motor. |

Capacitance Value | High (100 to 1600 µF). | Low (5 to 100 µF). |

Voltage Rating | Lower voltage ratings (125-330 V). | Higher voltage ratings (370-440 V). |

Connection | Temporarily connected during startup. | Remains connected during operation. |

Materials | Electrolytic. | Metallized film or ceramic. |

Applications | Ideal for high starting torque in single-phase motors. | Suitable for motors running for long durations. |

This comparison helps you understand the differences between start capacitor vs run capacitor. Selecting the right capacitor ensures optimal motor performance and prevents unnecessary wear and tear.

When to Use Each Type of Capacitor

Scenarios for Using a Start Capacitor

You should use a start capacitor in situations where motors require a high starting torque. These capacitors are essential for single-phase motors that need an initial energy boost to overcome inertia. For example, when starting an air conditioner or refrigerator, the start capacitor ensures the compressor motor begins rotating efficiently. Without it, the motor might fail to start or produce only a humming sound.

Start capacitors are also common in industrial machinery like pumps and compressors. These machines often demand a significant amount of torque during startup. The high capacitance values of start capacitors, ranging from 25 µF to 1,400 µF, make them ideal for such applications. Their voltage ratings typically fall between 110 Vac and 330 Vac, ensuring they can handle the energy surge required during startup.

Here’s a quick reference table for start capacitor specifications:

Specification | Value Range |

|---|---|

Start Capacitor Rating | 25 µF to 1,400 µF |

Voltage Rating | 110 Vac to 330 Vac |

If you’re working with single-phase motors in appliances or industrial equipment, a start capacitor is often the best choice for reliable motor startup.

Scenarios for Using a Run Capacitor

Run capacitors are necessary for motors that operate continuously over extended periods. These capacitors maintain a steady flow of current, ensuring smooth and efficient motor performance. You’ll find them in applications like HVAC systems, where they keep fan and blower motors running efficiently. Washing machines and refrigerators also rely on run capacitors to maintain consistent operation during their cycles.

In industrial settings, run capacitors are critical for machinery like conveyor belts and irrigation pumps. These systems require continuous operation to ensure productivity and reliability. The lower capacitance values of run capacitors, typically between 5 µF and 100 µF, make them suitable for maintaining stable current flow without overheating. Their higher voltage ratings, usually 370 or 440 VAC, allow them to handle the demands of long-term use.

If your motor needs to run for extended periods, a run capacitor is the right choice. It ensures continuous operation while reducing energy consumption and wear on motor components.

Can Start and Run Capacitors Be Interchanged?

You might wonder if start and run capacitors can be used interchangeably. While they both play vital roles in motor operation, their functions and designs are not interchangeable. Start capacitors provide the initial energy burst needed to start a motor, while run capacitors support continuous operation. Using a start capacitor in place of a run capacitor could lead to overheating and motor failure. Similarly, replacing a start capacitor with a run capacitor would prevent the motor from starting effectively.

Here are some key points to remember:

Start capacitors deliver the energy needed to start a motor.

Run capacitors ensure the motor operates efficiently during continuous use.

Interchanging these capacitors can result in inefficiency or motor damage.

Always use the correct capacitor type for your motor to ensure optimal performance and longevity.

Common Issues and Maintenance

Signs of a Faulty Start Capacitor

A faulty start capacitor can cause several noticeable issues in single-phase motors. One of the most common signs is when the motor fails to start. Instead of running, it may produce a humming sound, indicating that it lacks the initial torque needed to begin operation. You might also notice that the motor starts slower than usual or struggles to reach its normal speed. These symptoms often point to a weakened or damaged capacitor.

Another sign to watch for is overheating. A failing start capacitor can overheat due to internal damage, which may cause it to bulge or leak. If you see physical damage, such as cracks or a swollen casing, the capacitor likely needs replacement. Ignoring these signs can lead to motor failure, so addressing the issue promptly is essential.

Signs of a Faulty Run Capacitor

A faulty run capacitor can disrupt the continuous operation of your motor. One of the first signs you might notice is a decrease in motor efficiency. The motor may run unevenly, vibrate excessively, or produce unusual noises. These issues occur because the capacitor can no longer maintain a stable magnetic field, leading to imbalanced performance.

Another common symptom is overheating of the motor. A failing run capacitor forces the motor to work harder, generating excess heat. This can shorten the motor's lifespan if not addressed. Additionally, you might observe a drop in energy efficiency. A faulty capacitor increases power consumption, which can result in higher electricity bills. Inspecting the capacitor for physical damage, such as burns or leaks, can help confirm the problem.

How to Test a Capacitor

Testing a capacitor helps you determine whether it is functioning correctly. You can use a multimeter to check its capacitance. First, disconnect the capacitor from the motor and discharge it to avoid electrical shock. Set your multimeter to the capacitance setting and connect the probes to the capacitor terminals. The reading should match the capacitance value printed on the capacitor. If the value is significantly lower, the capacitor is likely faulty.

Standardized testing methods also validate capacitor performance. For example, high-reliability testing assesses how well a capacitor performs under various conditions. Burn-in procedures expose capacitors to stress to identify early failures. Dielectric withstanding voltage tests ensure the capacitor can handle high voltages without breaking down. The table below summarizes these methods:

Testing Method | Purpose |

|---|---|

High Reliability Testing | Assesses reliability and performance under various conditions. |

Burn-in Procedures | Identifies early failures by subjecting capacitors to stress conditions. |

Dielectric Withstanding Voltage | Ensures capacitors can withstand high voltages without failure. |

Insulation Resistance (IR) | Measures the resistance of the capacitor to ensure it meets standards. |

Thermal Shock | Tests the capacitor's ability to handle rapid temperature changes. |

Solderability | Assesses the capacitor's ability to be soldered without issues. |

Solder Leach Resistance | Evaluates the durability of the capacitor's termination during soldering. |

These methods ensure capacitors meet performance standards and operate reliably. Regular testing can help you identify issues early and prevent motor damage.

Safety Tips for Handling Capacitors

Handling capacitors requires caution to ensure your safety and prevent damage to the components. Capacitors store electrical energy, even after being disconnected from a power source. Mishandling them can result in electric shocks or equipment failure. Follow these safety tips to protect yourself and your equipment.

Discharge the Capacitor Before Handling

Always discharge a capacitor before touching it. Use a resistor or a capacitor discharge tool to safely release the stored energy. Avoid using a screwdriver or other metal objects, as this can cause sparks or damage the capacitor.Wear Protective Gear

Use insulated gloves and safety goggles when working with capacitors. These protect you from accidental shocks and shield your eyes from potential debris if the capacitor fails.Inspect for Physical Damage

Before handling, check the capacitor for signs of damage, such as bulging, cracks, or leaks. A damaged capacitor can be hazardous and should be replaced immediately.Handle with Care

Avoid dropping or applying excessive force to a capacitor. Physical impact can damage its internal components, reducing its effectiveness or causing it to fail.Follow Manufacturer Guidelines

Always adhere to the manufacturer’s instructions for installation and handling. This ensures proper use and minimizes risks.

Note: Capacitors, especially high-voltage ones, can retain a charge for a long time. Never assume a capacitor is safe to handle without testing or discharging it first.

By following these precautions, you can safely handle capacitors and avoid accidents.

Preventive Maintenance for Capacitors

Regular maintenance ensures capacitors, including both start capacitors and run capacitors, perform efficiently and last longer. A proactive approach can help you identify potential issues before they lead to motor failure.

Schedule Routine Inspections

Inspect capacitors regularly for physical damage, such as bulging, leaks, or discoloration. These signs often indicate a failing capacitor that needs replacement.Test Capacitance Levels

Use a multimeter to measure the capacitance of your capacitors. Compare the readings to the manufacturer’s specifications. A significant deviation suggests the capacitor is deteriorating.Monitor Operating Conditions

Ensure capacitors operate within their specified voltage and temperature ranges. Overloading or exposing them to extreme conditions can shorten their lifespan.Replace Aging Capacitors

Capacitors degrade over time, even with proper use. Replace them according to the manufacturer’s recommended schedule to maintain optimal motor performance.Use High-Quality Components

Quality capacitor design and materials are crucial for longevity. Adhering to industry standards and implementing quality control during production significantly impacts their service life.Keep the Environment Clean

Dust and debris can accumulate around capacitors, leading to overheating. Regularly clean the area to ensure proper ventilation and cooling.

Tip: Implementing a maintenance schedule that includes performance testing and adherence to industry standards can extend the lifespan of your capacitors. For example:

Use quality materials during installation.

Conduct dielectric withstanding voltage tests periodically.

Follow thermal shock testing procedures for capacitors in extreme environments.

Preventive maintenance not only extends the life of your capacitors but also ensures the smooth operation of your motor-driven systems.

Start and run capacitors play vital roles in motor performance. Selecting the correct type ensures efficient operation and extends the motor's lifespan. Regular maintenance prevents costly repairs and keeps your equipment running smoothly.

Capacitors enable stable and efficient motor operation.

Proper selection and upkeep improve reliability and performance.

Understanding failure causes helps you implement preventive measures.

Following manufacturer guidelines ensures long-term stability.

By prioritizing capacitor care, you can enhance motor efficiency and avoid unexpected breakdowns. This proactive approach safeguards your investment and ensures consistent performance.

FAQ

What happens if a capacitor fails in a motor?

When a capacitor fails, the motor may not start or run efficiently. You might hear a humming sound or notice overheating. Replacing the faulty capacitor promptly prevents further damage to the motor.

Can you test a capacitor without a multimeter?

Yes, you can test a capacitor using a simple bulb circuit. Connect the capacitor to the circuit. If the bulb lights up briefly, the capacitor stores and releases energy. This method is less precise than using a multimeter.

How do you choose the right capacitor for a motor?

Select a capacitor based on the motor's voltage and capacitance requirements. Check the motor's specifications and match them with the capacitor's ratings. Using the wrong type can reduce efficiency or damage the motor.

Why do start capacitors disconnect after the motor starts?

Start capacitors disconnect to prevent overheating. They provide a temporary energy boost during startup. Once the motor reaches operating speed, a centrifugal switch or relay disengages the capacitor.

Can you replace a capacitor with a higher voltage rating?

Yes, you can use a capacitor with a higher voltage rating as long as the capacitance matches the motor's requirements. Higher voltage ratings improve durability but don’t affect performance directly.

How often should you replace capacitors?

Replace capacitors every 5-10 years or when signs of failure appear, such as bulging or leaking. Regular inspections help identify issues early and ensure reliable motor operation.

Are start and run capacitors interchangeable?

No, start and run capacitors serve different purposes. Start capacitors provide an energy boost during startup, while run capacitors maintain continuous operation. Using the wrong type can damage the motor.

What safety precautions should you take when handling capacitors?

Discharge capacitors before handling them to avoid electric shocks. Wear insulated gloves and goggles. Inspect for physical damage and follow manufacturer guidelines for installation and maintenance.

See Also

Exploring Various Capacitor Types and Their Unique Features

Key Historical Developments in Capacitor Technology Explained

Essential Steps to Remember When Testing Supercapacitors