Understanding the Purpose of Capacitors in Electronics: Past to Present

A capacitor keeps and gives out electrical energy in a circuit. This makes it very important for how devices work. Think of a water tank that holds water and lets it out when needed. A capacitor does this with electricity. Since 1745, inventors like Ewald Georg von Kleist and Pieter van Musschenbroek helped change the capacitor:

The Leyden jar was made in 1745. It was the first try to store electricity.

Early capacitors used glass bottles filled with water or alcohol.

In the 1900s, ceramic materials made designs smaller and better.

Today, the purpose of capacitor is still very important. We use them in things like smartphones and cars. The story of the capacitor shows how one idea can change technology for a long time.

Key Takeaways

Capacitors hold and let go of electrical energy. They act like tiny batteries in circuits. This helps devices run well.

The Leyden jar was made in 1745. It was the first capacitor. It began the history of capacitor growth.

Today’s capacitors are much smaller and stronger. They are very important in phones, cars, and many gadgets.

There are many kinds of capacitors. They use different materials and shapes. Each kind fits a special job, like filtering signals or saving energy.

Supercapacitors can hold more energy and give it out fast. They are very important in electric cars and clean energy.

Surface-mount capacitors help make electronics smaller and faster. They also help save energy.

Capacitors help control voltage and filter out noise. They also help set timing in circuits. This makes devices work better and last longer.

New materials and nanotechnology keep making capacitors better. This helps new things like 5G and smart gadgets.

Purpose of Capacitor

Basic Function

The purpose of capacitor is to store and give out energy. It works like a small battery in a circuit. It charges up and then gives back energy when needed. This happens because it holds electric charge on two plates. The plates are separated by a material that does not let electricity pass. You can think of it like a water tank. The tank fills up and lets water out when needed.

Capacitance tells us how much charge a capacitor can hold. The formula is C = Q/V. C is capacitance in farads. Q is the charge in coulombs. V is the voltage. The energy stored is E = 1/2 CV². These formulas show how size and material matter. In a simple RC circuit, the charge goes up fast at first. Then it slows down. The equation is Q(t) = CV(1 - e^(-t/RC)). This helps us see why capacitors are important. They help control how electricity moves in a circuit.

Why It’s Essential

The purpose of capacitor made it important in old and new electronics. Early capacitors like the Leyden jar were big and held little charge. Modern ones are much smaller and hold more energy. This lets engineers use them in almost every device today.

Capacitor Type | Dielectric Constant (K) | Capacitance Range | Voltage Rating | Notable Features / Role in Electronics |

|---|---|---|---|---|

Leyden Jar (Early) | ~1 (air) | Very low capacitance | Large and bulky | Early capacitor, bulky, low capacitance |

Mica | 9 | N/A | N/A | Used for stable capacitance |

Glass | 6 | 0.5 to 10,000 pF | 300-500 V | High reliability, used in military and space applications |

Ceramics | 10 to 10,000 | N/A | N/A | High capacitance-to-volume ratio, used in tuning and filtering |

Film Capacitors | N/A | 5 pF to 100 µF | N/A | Miniaturized, self-healing, used in many modern circuits |

Tantalum (Solid) | N/A | 6.8 µF | 50 V | Very high capacitance per volume, tiny size |

This table shows how capacitors changed over time. Old ones could not fit in small devices. Now, engineers use tiny capacitors with high capacitance. They are in smartphones, computers, and cars. Capacitors are key for storing energy, filtering, and timing in these devices.

Common Uses

Capacitors are in almost every electronic device. They store energy, filter signals, help with timing, and sense things. In a camera flash, a capacitor stores energy and lets it out fast. This makes a bright light. In power supplies, capacitors smooth out voltage changes. This protects sensitive parts. Many sensors use capacitors to measure pressure or humidity.

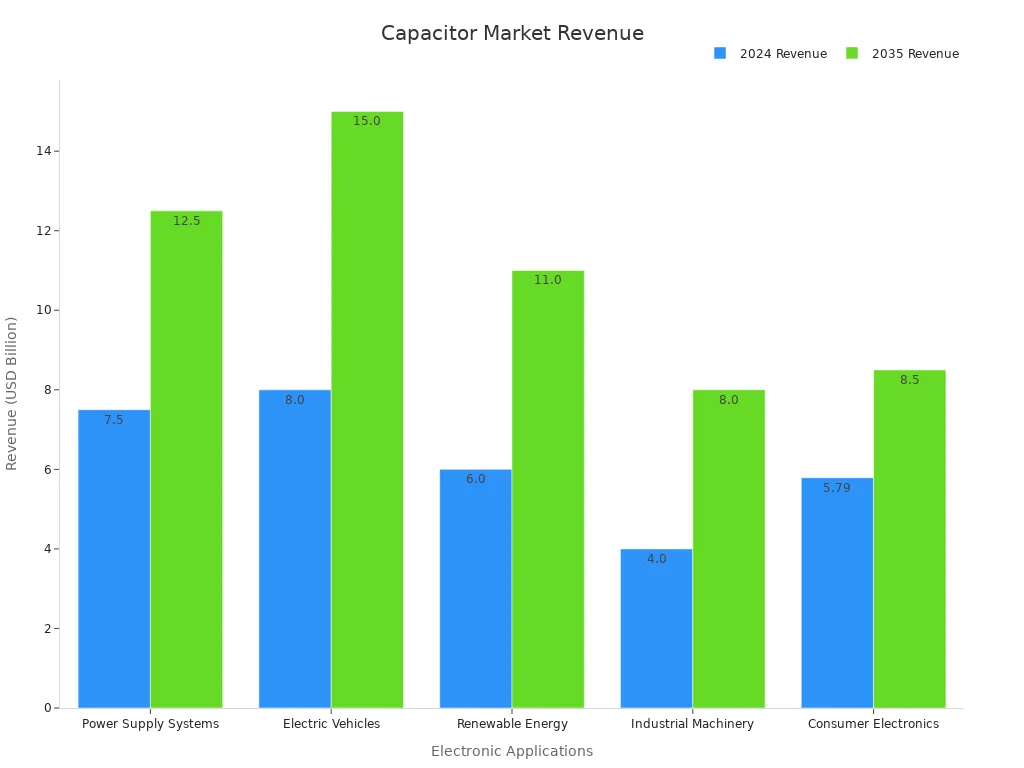

Application Area | Projected Revenue 2035 (USD Billion) | Key Use Case Highlights | |

|---|---|---|---|

Power Supply Systems | 7.5 | 12.5 | Voltage stabilization, power delivery efficiency |

Electric Vehicles | 8.0 | 15.0 | Energy storage and management in EV power electronics |

Renewable Energy | 6.0 | 11.0 | Energy storage solutions, inverters for sustainable energy |

Industrial Machinery | 4.0 | 8.0 | Enhancing operational efficiency and reliability in manufacturing |

Consumer Electronics | 5.79 | 8.5 | Efficient power management in everyday electronic devices |

Capacitors also help control radio and TV signals. In computers, they keep voltage steady for chips. In electric cars, they manage energy and make them work better. The purpose of capacitor is still very important as technology grows. They help new things like renewable energy and smart devices.

Tip: When you use a smartphone or turn on a light, a capacitor is working inside to help make it happen.

How Capacitors Work

Storing Charge

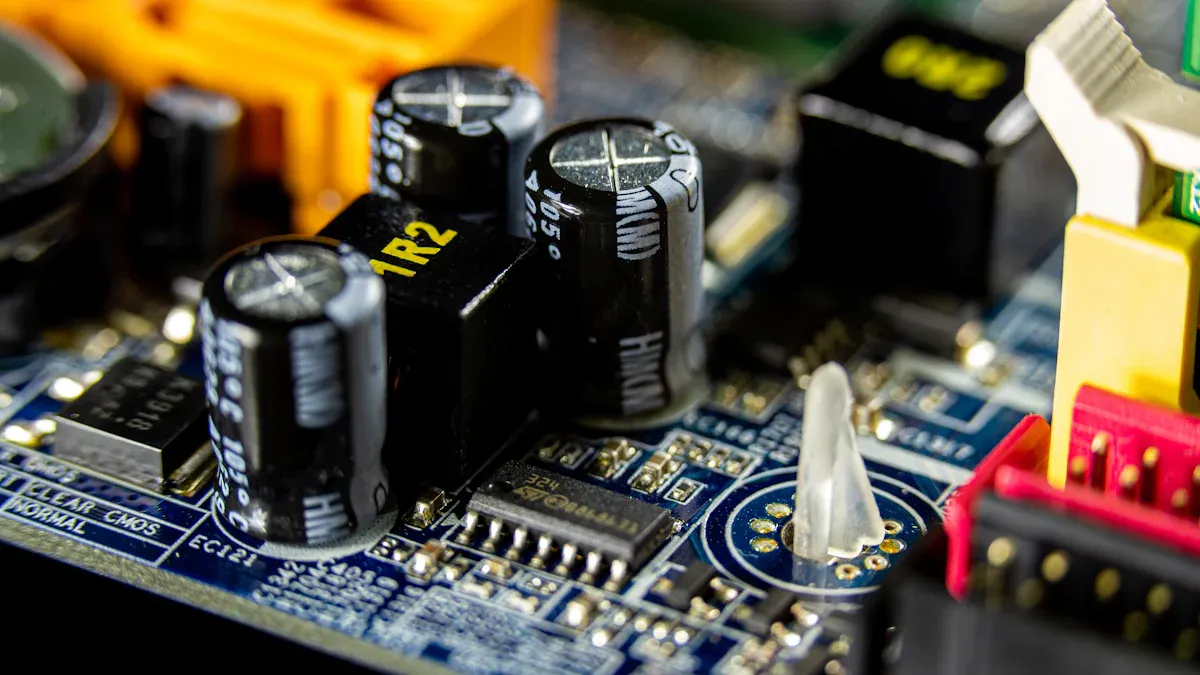

A capacitor keeps energy by holding electric charge on two metal plates. The plates are close but do not touch each other. A dielectric sits between the plates and stops electricity from passing through. When voltage is added, electrons gather on one plate and leave the other. This makes an electric field between the plates. The capacitor can give out or take in energy when needed.

Scientists use different ways to see how much charge a capacitor can hold and how it works:

Galvanostatic charge/discharge tests show how fast a capacitor charges and loses charge.

Cyclic voltammetry helps check how charge moves inside the device.

Electrochemical impedance spectroscopy shows how the capacitor acts at different frequencies.

The shape of the electrodes and the kind of electrolyte change how much charge the capacitor can keep.

For smooth metal surfaces, the electrochemical double layer capacitance is about 20 microfarads per square centimeter.

If the discharge current is low, a supercapacitor can give out more charge. For example, one test showed the charge went up from about 250 coulombs at 10 amps to almost 300 coulombs at 0.01 amps. This happens because slower currents give more time for charge to leave the capacitor.

Note: After a capacitor gives out its charge, some still show a small voltage left. This is called dielectric relaxation or soakage. It happens because some charge gets stuck and moves slowly inside the material.

Capacitance and Dielectric

Capacitance tells how much charge a capacitor can keep for a certain voltage. The formula is:

Concept | Formula / Definition | Example Value / Note |

|---|---|---|

C = Q / V | Charge stored per unit voltage | |

Parallel Plate Capacitor | C = ε₀ × A / d | ε₀ = 8.85 × 10⁻¹² F/m, A = area, d = distance |

Example Calculation | For A = 1 m², d = 1 mm: C = 8.85 nF | |

Stored Charge (Q) | Q = C × V | For V = 3,000 V, Q = 26.6 μC |

Dielectric Effect | Capacitance increases by dielectric constant κ | κ changes with material between plates |

Measurement Techniques | Insulating films help improve accuracy | |

Sensor Application | Capacitance immunosensors detect tiny changes | Detection limits down to 0.5 ng/l for some sensors |

The dielectric between the plates makes the capacitance higher. Glass, ceramic, or plastic have different dielectric constants. If the dielectric constant is higher, the capacitor can keep more charge. LCR meters help measure capacitance, but results depend on the electrodes and materials used.

Types Overview

Capacitors come in many types, and each has special uses:

Ceramic capacitors use ceramic as the dielectric. They are small and good for high-frequency circuits.

Electrolytic capacitors have a liquid or gel inside. They hold a lot of charge and are used in power supplies.

Film capacitors use thin plastic films. They last long and can handle high voltages.

Supercapacitors keep much more charge than regular capacitors. They are used for energy storage and backup power.

Each type of capacitor helps engineers fix different problems. Some are best for filtering signals. Others are better for keeping lots of energy. The type chosen depends on what the circuit needs.

History of Capacitors

Early Discoveries

People started learning about capacitors in the 1700s. Scientists wanted to find a way to keep electricity safe. The leyden jar was the first tool that could do this.

Leyden Jar

In 1745, Ewald Georg von Kleist and Pieter van Musschenbroek made the leyden jar. It was a glass jar with water and a metal rod inside. If you touched the rod after charging it, you got a shock. The leyden jar could hold static electricity. This was a big step for science. People learned the glass stopped electricity, but water and metal let charge build up.

Benjamin Franklin helped make the leyden jar better. He put metal foil inside and outside the glass. This made it safer and worked better. The leyden jar was the start of all capacitors.

Period | Key Development | Inventor/Contributor | Description & Significance |

|---|---|---|---|

1745 | Leyden Jar | Ewald Georg von Kleist, Pieter van Musschenbroek | First capacitor design storing static electricity; glass jar with metal foil; foundational for capacitor concept. |

1750 | Glass–Metal Foil | Benjamin Franklin | Improved safety and efficiency by adding metal foil to the jar. |

Late 1800s | Practical capacitors for wireless | Guglielmo Marconi (application) | Use of porcelain capacitors in spark-gap transmitters; high voltage and frequency demands; large size due to Leyden jar design. |

1909 | Mica capacitors | William Dubilier | Smaller capacitors using layers of mica and copper foil; early versions had reliability issues due to air gaps causing oxidation. |

1920s | Silver mica capacitors | Unknown | Improved mica capacitors with metal coating on both sides, eliminating air gaps and improving reliability and size. |

1920s-1940s | Ceramic capacitors | German researchers | Developed due to mica scarcity; used titanium dioxide (rutile) for temperature compensation; produced in increasing quantities. |

The leyden jar started the first years of capacitor technology. Scientists found out that bigger jars and different materials could hold more charge. Michael Faraday later showed that the charge depends on capacitance and voltage. This helped make better capacitors.

Ewald Georg von Kleist

Ewald Georg von Kleist was important in capacitor history. In 1745, he found a glass jar could keep electricity. He put a nail through the cork and filled the jar with water. Pieter van Musschenbroek in Leyden found the same thing. Their work gave us the name "leyden jar." These inventors started many new ideas.

The Term 'Condenser'

In the 1700s and 1800s, people called capacitors "condensers." Scientists picked this word because the device seemed to squeeze electric charge into a small space. "Condenser" was in many old books and papers. As people learned more about electricity, "capacitor" became the main word. Today, engineers say "capacitor," but some old things still use "condenser."

Material Evolution

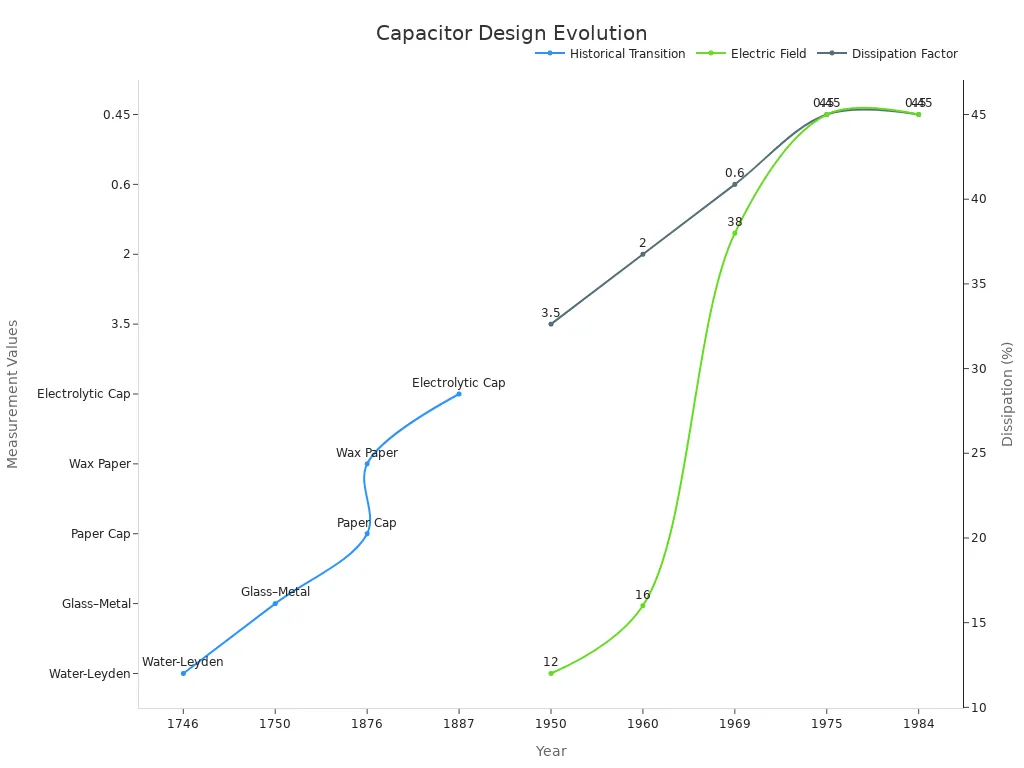

Capacitors changed as people tried new materials and designs. After the leyden jar, inventors wanted better ways to store energy. In 1750, Franklin’s glass–metal foil design used metal foil instead of water. This made the device work better. By 1876, engineers used paper as the dielectric. This made capacitors smaller and easier to use. Waxed paper made them safer and stopped leaks.

John Bevis and D. G. Fitzgerald tried different materials too. In 1887, electrolytic capacitors were made. These could hold even more charge. During World War II, people used lacquered paper to make capacitors stronger. By the 1950s, plastic films like polyethylene and polystyrene replaced paper. These new materials were stronger and lost less energy.

The chart below shows how capacitor materials and performance got better over time:

Capacitor Type | Approximate Year | Key Material/Design Transition |

|---|---|---|

Water-filled Leyden Jar | 1746 | Water as dielectric |

Franklin’s Glass–Metal Foil | 1750 | Introduction of glass and metal foil |

Paper Capacitors | 1876 | Use of paper as dielectric |

Wax Paper–Metal Foil | 1876 | Paper impregnated with wax |

Electrolytic Capacitor | 1887 | Electrolyte-based design |

Lacquer on Paper | WWII | Paper impregnated with lacquer |

Starting 1954 | Transition to polymer films (PE, PS, PTFE, PET, BOPP) |

Capacitors worked better as materials changed. Old paper capacitors could not handle much electricity and lost a lot of energy. By the 1980s and 1990s, all-film capacitors could take higher voltages and lost less energy. This made them more useful for new electronics.

Note: The story of capacitors goes from simple jars with water to strong plastic films. Each new material made capacitors work better and do more things.

The history of capacitors shows how inventors kept making things better. From the leyden jar to today’s designs, each step helped electronics grow.

Advancements in the 19th and 20th Century

Electrolytic Capacitors

In the late 1800s, capacitor technology improved a lot. In 1866, Warren de la Rue made the electrolytic capacitor. This kind used a liquid or gel for the dielectric. Engineers could now make smaller capacitors with more capacitance. These were very important for early radios. Radios needed to store and release energy quickly. Better electrolytic capacitors helped radios work better and reach more people. Over time, new materials and better seals made them safer and last longer. Their small size and high capacity helped make new electronic devices possible.

Tip: Electrolytic capacitors are still used today in power supplies and audio gear. They can hold a lot of energy in a small space.

Paper and Foil Designs

In the 19th and 20th centuries, inventors tried new materials for capacitors. Paper capacitors used special paper as the dielectric. Metal foil was used for the electrodes. These could handle up to 6,300 volts. But they were big and sometimes not stable. Later, engineers made metalized paper capacitors. They put a thin metal layer on the paper. This made them smaller and gave them a self-healing feature. This made them last longer and work better.

The table below shows how capacitor designs got better over time:

Capacitor Type | Technical Feature | Performance Improvement |

|---|---|---|

Paper Capacitors | Paper dielectric, foil electrodes | Capacitance up to 100μF, high voltage, bulky |

Metalized Paper Capacitors | Thin metal film on paper, self-healing | Smaller size, higher reliability, longer lifespan |

Foil Polypropylene Capacitors | Metal foil, stable dielectric | High precision, used in motor circuits |

Metalized Polypropylene Capacitors | Metal layer, compact design, self-healing | Better efficiency, cost-effective, used in high-power circuits |

Multilayer Ceramic Capacitors | Thin ceramic layers, compact | High capacitance density, low leakage, small size |

These changes made capacitors more reliable and easier to use. New materials like polypropylene and ceramics made them work even better. They were great for high-frequency and high-power circuits.

Role in Early Electronics

Capacitors were very important for early electronics. The Leyden jar was the first one, made in the 1700s. By the 1800s, new materials like glass, wax, and paper helped capacitors store more energy. The electrolytic capacitor let people build smaller radios and other devices. As technology got better, surface-mount capacitors were made in the mid-1900s. These tiny parts helped make transistor radios and early computers.

Here is a timeline of important moments in capacitor history:

The Leyden jar (1745-1746) was the first to store charge.

Benjamin Franklin (1750) linked Leyden jars and studied electricity.

The 1800s brought better materials like glass, wax, and paper.

In 1866, the electrolytic capacitor made small, high-capacitance designs.

By the mid-1900s, small capacitors powered transistor radios and computers.

Better capacitors made modern electronics possible. Each new design and material helped engineers make smaller, faster, and more reliable devices.

Modern Capacitor Technology

Surface-Mount Devices

Surface-mount devices, or SMDs, changed how engineers build electronics. SMD capacitors are much smaller than old ones. They fit on circuit boards with great accuracy. Machines put these parts on boards very fast. This makes building electronics quicker and cheaper.

SMD capacitors let more parts fit on one board. This helps make phones, tablets, and wearables smaller and lighter.

SMDs have short paths for electricity. This cuts down on unwanted signals and makes things faster.

Multilayer Ceramic SMD Capacitors, called MLCCs, hold a lot of charge in a tiny size. They last longer because they are made well.

SMD electrolytic capacitors store lots of energy in a small space. Clear labels help machines put them in the right spot.

SMDs also save energy and use fewer materials. This helps make electronics better for the planet.

These things show why SMD capacitors matter so much today. They help make electronics smaller and work better.

High-Performance Types

Engineers use many kinds of high-performance capacitors for new technology. Each type has special features for different jobs.

Capacitor Type | Key Technical Specifications and Performance Metrics |

|---|---|

Polymer Electrolytic | Low ESR, high ripple current, long life, stable performance, self-healing |

Supercapacitors | Very high energy density, large capacitance, low ESR, long cycle life |

Hybrid Lithium-ion Capacitors | Mix of double-layer and faradaic capacitance, higher voltage, no thermal runaway, polarized, higher cost |

Vacuum Capacitors | Very low losses, high voltage, self-healing, used in high-frequency radio |

SF6-gas Filled Capacitors | High precision, low losses, stable, very high voltage, used as standards in labs |

Metallized Mica Capacitors | High stability, no aging, low losses, used in radio circuits and as standards |

Miniaturization Trends | Better efficiency, smaller size, lower inductance for high-frequency work |

ESR and Dissipation Factors | Low ESR means less heat and better efficiency |

Wide temperature range, ripple current limits, long service life, tested for reliability |

Capacitors now work faster and in harder places. Supercapacitors can store much more energy than old ones. Polymer electrolytic capacitors last longer and handle more power. These changes help devices run faster and last longer.

Applications Today

Capacitors are in almost every modern device. Smartphones use between 600 and 1,000 MLCCs each. Modern cars need over 3,000 MLCCs. Electric vehicles use more than 10,000 MLCCs. The newest smartphones use MLCCs as small as 0.6mm by 0.3mm. Asia Pacific makes about 60% of all capacitors.

The table below shows how often capacitors are used today:

Application/Context | Numerical Data/Metric |

|---|---|

Average MLCCs in smartphones | 600 to over 1000 |

MLCCs in modern cars | Over 3,000 |

MLCCs in electric vehicles | Over 10,000 |

MLCC size in latest smartphones | 0201 size (0.6mm x 0.3mm) |

Market share of Asia Pacific | Approximately 60% |

Capacitors help control power, clean up signals, and store energy. They keep devices working safely and smoothly. Today’s capacitors are important for things like green energy and electric cars. As technology grows, we will need even better capacitors.

Evolving Role in Technology

Power and Energy Storage

Capacitors are important for storing and giving out energy fast. Supercapacitors are special because they have high power density. They can send out energy much quicker than batteries. This is helpful for things like electric cars and backup power. Supercapacitors use materials with lots of surface area and special parts to hold more energy than normal capacitors. They last longer because they do not break down after many uses.

Supercapacitors are between regular capacitors and batteries. They give high power and store a fair amount of energy.

Ragone plots show supercapacitors give more power but less energy than batteries.

They work well for a long time and do not lose much ability.

Engineers check their specific capacitance to see how good they are.

Supercapacitors use materials that conduct electricity and special separators to work well.

Tests show these devices store energy right away and keep working well, even after many uses. This makes them good for green energy and electric cars.

Filtering and Timing

Capacitors help control and shape electric signals in circuits. They smooth out voltage changes, filter out noise, and set timing in electronics. Different types of capacitors are best for different jobs. The table below shows how each type helps with filtering and timing:

Capacitor Type | Key Characteristics | Filtering and Timing Relevance |

|---|---|---|

Electrolytic | High capacitance, moderate to high ESR, moderate temperature stability | Used for power supply smoothing and low-frequency filtering |

Ceramic | Low ESR, good high-frequency performance, good temperature stability | Ideal for high-frequency filtering and stable timing |

Film | Low ESR, excellent stability, low dielectric loss | Used in audio processing and precise timing circuits |

Capacitors store energy and let it out fast to help with sudden power needs. They remove unwanted noise by making power supplies smoother. In timing circuits, how fast a capacitor charges and discharges sets how long a signal lasts. Low ESR and steady capacitance help make timing and filtering better. Small capacitors in surface-mount technology make today’s devices smaller and more reliable.

Tip: In a digital watch, a tiny capacitor helps keep time by controlling the oscillator.

Emerging Uses

Capacitors are being used in more ways as technology grows. New uses are found in 5G networks, electric cars, and green energy. The market for advanced capacitors like MIS capacitors may grow from $2.5 billion in 2025 to $4.5 billion by 2033. This is because of trends like making things smaller, higher capacitance, and better energy use.

Consumer electronics, phones, and car electronics need new capacitor types.

Better materials, like high-k dielectrics, make capacitors work better and last longer.

High-speed uses, like 5G and factory machines, need capacitors that work well at fast speeds.

Big companies and government groups help create new and greener electronics.

Capacitors now help smart devices, fast networks, and clean energy. Their changing role is helping shape the future of technology.

Future Trends

Supercapacitors

Supercapacitors are a big new idea for storing energy. They keep energy by separating charges and using fast reactions at the edge of the electrode and electrolyte. Engineers use special materials like activated carbon, carbon nanotubes, graphene, and metal oxides to make them. Supercapacitors can give out power very fast, up to 10,000 W/kg. They last much longer than batteries and can be charged and used many times.

Parameter | Description / Data |

|---|---|

Charge Storage Mechanism | Electrostatic separation (EDLCs) and fast redox reactions (pseudocapacitors) at electrode/electrolyte interface |

Electrode Materials | Activated carbon, carbon nanotubes, graphene, metal oxides, conducting polymers, MXenes |

Electrolytes | Aqueous, organic, ionic liquids |

Specific Capacitance | Enhanced by novel electrode materials and composites |

Energy Density | Higher than electrolytic capacitors, lower than batteries |

Power Density | Up to 10,000 W/kg |

Charge/Discharge Time | Typically under 1 hour |

Cycle Life | 100,000 to 1 million cycles |

Operating Temperature | Effective down to -40 °C |

Safety | Less heat generation, safer operation |

Ragone Plot Position | Between electrolytic capacitors and batteries |

Future Developments | Focus on nanostructured materials, hybrid composites, flexible SCs |

Supercapacitors already help run electric buses and backup power systems. They work well for renewable energy and electric cars because they react fast and last a long time. Scientists are working to make them store more energy and bend without breaking.

Nanotechnology

Nanotechnology changes how capacitors work by using tiny materials. Scientists use carbon nanotubes, graphene, and metal oxides to make electrodes with lots of surface area. These small materials help capacitors hold more energy and give it out faster. Computers and machine learning help scientists design better materials and see how ions move inside.

Aspect | Description | Supporting Details |

|---|---|---|

Nano-engineering approaches | Nanoporous and nanostructured electrodes | Increases active surface area, boosts capacitance and power |

Nanomaterials used | CNTs, graphene, metal oxides, polymers | CNTs reach up to 113 F/g, graphene and oxides improve performance |

Composite nano-architectures | Material combinations | Achieve high pseudo-capacitance, long cycling life |

Flexible nanostructured electrodes | CNT paper, PANI/CNT films | Enable flexible supercapacitors, though energy density remains a challenge |

Micro-supercapacitors | Printable micro-devices | Used in smart sensors and drug delivery |

Application examples | Provide peak power, improve fuel economy, long cycle life | |

Challenges | High fabrication cost, low mass loading | Limits commercial use; need for cost-effective methods |

Electrolyte and device design | Stable organic electrolytes, hybrid devices | Increase voltage window and energy density |

Flexible and printable supercapacitors might soon power smart watches and sensors. But making them costs a lot and they cannot hold much material yet, so using them everywhere is hard.

Next-Gen Applications

Capacitor technology keeps changing for new uses. Dry type and oil-filled capacitors will keep growing because of green energy, electric cars, and smart power grids. The dry type market could reach $3.8 billion by 2032, and oil-filled ones may reach $4.5 billion. Supercapacitors are being used more in electric cars, backup power, and green energy storage. China and India are leading, with new rules and factories for green transport.

Supercapacitors help run electric buses, and China added 54,000 new buses in 2022.

Asia-Pacific is growing fast because of new factories for making capacitors.

Flexible and tiny supercapacitors could soon power smart sensors, medical tools, and wearable gadgets.

Market research says high reliability capacitors will stay important for planes, the military, cars, and hospitals. As technology gets better, capacitors will get smaller, work better, and be kinder to the planet. New research will help fix problems and bring new ideas for electronics.

Capacitors have changed electronics a lot, starting with the Leyden jar. Their story has many steps. First, the Leyden jar was invented in the 1700s. Benjamin Franklin did some of the first experiments. In the 1800s, people used glass, wax, and paper to make capacitors. In 1866, the electrolytic capacitor was made. In the 1900s, capacitors got much smaller. Today, supercapacitors help run new technology.

Now, new ideas keep making capacitors better. Smart capacitor banks help control energy right away. New electrode materials let them store more energy. Machine learning helps guess how long they will last. Capacitors also help with green energy and smart power systems.

Learning how a capacitor works helps us see why it matters. As scientists learn more, capacitors will be even more important. When someone uses a phone or rides in an electric car, they can think about the small but important capacitor inside.

FAQ

What does a capacitor do in a circuit?

A capacitor keeps energy and lets it out when needed. It helps control how electricity moves in a circuit. Many devices use capacitors to keep power steady or clean up signals.

Why do engineers use different types of capacitors?

Engineers pick capacitor types by size, voltage, and how much energy they need. Some types work better for fast signals. Others last longer or can handle more power.

Can a capacitor replace a battery?

A capacitor cannot take the place of a battery for long-term energy. It gives out energy fast but cannot hold as much as a battery. Supercapacitors are good for short bursts of power.

How do you know if a capacitor is bad?

A bad capacitor might bulge, leak, or make a device stop working. Technicians use a multimeter to check if a capacitor can still hold a charge.

Where can you find capacitors in everyday life?

Capacitors are inside many things. Phones, computers, TVs, and cars all use them. Even a camera flash uses a capacitor to make a bright light.

What happens if you connect a capacitor the wrong way?

Electrolytic capacitors have a positive and negative side. If you connect them backward, they might leak, get hot, or even burst. Always look at the markings before you connect one.

Why do capacitors matter for renewable energy?

Capacitors help store and give out energy fast in solar panels and wind turbines. They smooth out power changes and protect important equipment.

Tip: Always be careful with capacitors. Some can keep a charge even after you turn off the device.

See Also

Tracing The Key Developments In Capacitor Technology History

Exploring The Function Of Capacitors Through Data Analysis

Comprehensive Overview Of Capacitor Types And Their Characteristics

Understanding The Roles Of Electronic Circuit Board Components