How PLC Controllers Improve Manufacturing Processes

In factories, a PLC controller is very important for work. It helps automate repeated tasks, making them faster and better. Using a PLC gives you exact control and fewer mistakes. These controllers handle data instantly, which is great for quick choices. They also connect with other systems to make work smoother. With PLCs, factories can become more efficient and dependable.

Key Takeaways

PLCs handle repeated tasks, making work faster and reducing mistakes.

Key parts of a PLC are the CPU, I/O modules, power supply, and programming tool. Each part helps with automation.

PLCs process information quickly, reacting fast to changes in production.

They are made to survive tough factory conditions, staying strong and reliable.

PLCs can be reprogrammed easily, helping businesses switch tasks smoothly.

Sensors in PLCs check things like temperature and pressure to improve product quality.

Connecting PLCs with systems like SCADA and ERP improves communication and work efficiency.

Keeping PLCs updated and maintained is important for them to work well.

Understanding PLC Controllers

What Is a PLC Controller?

A Programmable Logic Controller (PLC) is a special device for automation. It works like the brain of machines, helping them run smoothly. Think of it as a smart helper that takes inputs, follows instructions, and controls outputs quickly. Many industries, like car-making, food factories, and energy plants, use PLCs. They are trusted because they control complex tasks with accuracy and dependability.

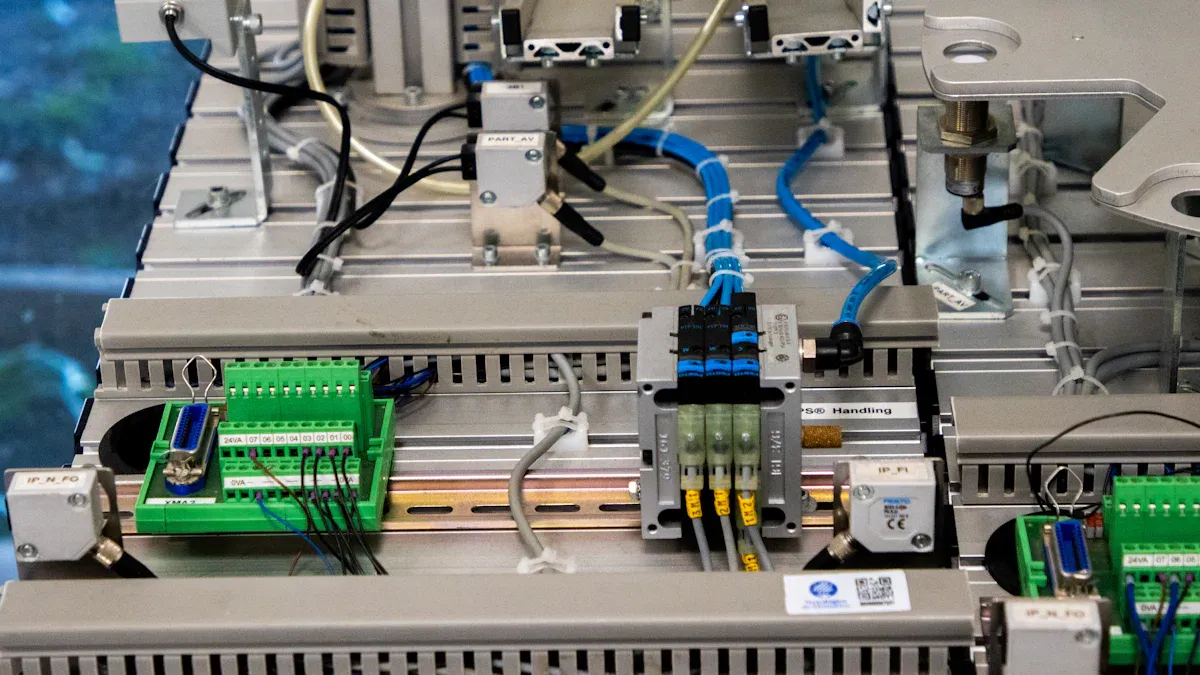

Core Parts of a Programmable Logic Controller

To know how a PLC works, you must learn its main parts. Each part is important to keep the system running well.

Central Processing Unit (CPU)

The CPU is the main part of the PLC. It reads data, runs commands, and talks to other devices. Inside, memory stores programs, and circuits handle logic and checks. This part makes sure the PLC works fast and reacts to changes right away.

Input/Output (I/O) Modules

I/O modules link the PLC to the outside world. Inputs get signals from sensors or switches, and outputs send commands to motors or lights. These modules handle both on/off and continuous signals. For example, on/off inputs check if something is there, while continuous inputs measure things like heat or pressure.

Type | Signal Type | Resolution | Typical Applications | Advantages |

|---|---|---|---|---|

Digital Output | On/Off | 1 bit | Motor control, valve actuation | Handles high power, safe isolation |

Analog Input | Continuous (4-20mA) | 12-16 bit | Heat measurement | Accurate for smooth values |

Analog Output | Continuous (4-20mA) | 12-16 bit | Speed control | Smooth and precise |

Digital Input | On/Off | 1 bit | Object detection | Quick and simple |

Power Supply

The power supply gives energy to the PLC. It changes regular electricity into the right type for the system. A steady power supply keeps the PLC working without stopping, which is very important in factories.

Programming Device

The programming device helps you write and upload programs to the PLC. It can be a computer or a small device with special software. This tool lets you change the PLC to do new jobs or meet production needs.

Key Features of PLCs

PLCs have many features that make them useful in factories.

Real-Time Processing

PLCs handle data and run commands instantly. This means systems can react fast, like slowing a conveyor or stopping a machine in an emergency.

Built Tough for Factories

PLCs are made to survive tough conditions like heat, shaking, and electrical noise. Their strong design keeps them working in hard environments.

Easy to Change and Expand

You can reprogram a PLC to do new tasks or add more I/O modules to expand it. This makes it great for businesses that need to grow or change.

Tip: Small businesses can also use PLCs. They are affordable and help automate tasks efficiently, even in smaller setups.

How PLC Controllers Work

Input Processing in PLCs

A PLC starts by collecting data from its surroundings. Sensors and switches notice changes like heat, pressure, or objects. They send signals to the PLC, which acts as input data. This information helps the system decide what to do next. For example, a sensor on a conveyor belt might spot an item and tell the PLC to move it forward.

This step ensures the PLC gets correct and timely data. Good input is important because it affects how well the system works. The PLC keeps checking these inputs all the time. This lets it react quickly to any changes.

Program Execution and Logic Control

After processing inputs, the PLC runs its program. It uses pre-set logic to decide what actions to take. This logic is written in special languages like ladder logic or structured text. A programming device uploads the logic to the PLC.

The process works in three steps:

Input: Sensors find items and send signals to the PLC.

Processing: The PLC uses logic to decide what to do.

Output: The PLC tells devices like motors or actuators what to do.

This method helps the PLC work fast and correctly. For example, in a bottling factory, the PLC fills bottles only when they are in the right spot.

Output Control Mechanisms

After running the program, the PLC sends commands to devices. These include motors, actuators, and lights that do the needed tasks. For instance, a motor might turn on or off, or an actuator might open a valve.

PLCs are great at controlling processes with precision. They manage things like heat, pressure, and flow rates very accurately. This reduces mistakes and keeps product quality steady. PLCs also handle repeated tasks, cutting down on human errors and speeding up production. They watch process changes and adjust instantly to keep things running smoothly.

By combining input, logic, and output, PLCs make workflows smooth and efficient. This helps factories save money, work faster, and produce better results.

Communication and Integration with Other Systems

Today’s factories need systems that work well together. A Programmable Logic Controller (PLC) is great at connecting and sharing data. It links to many devices, helping everything run smoothly.

How PLCs Communicate

PLCs use special "languages" called communication protocols to share data. These let different devices understand each other. Common protocols include:

Modbus: Simple and used in many industries.

Ethernet/IP: Fast and good for complex networks.

Profibus: Often used in factories for sensors and actuators.

CAN Bus: Common in cars and machine controls.

Note: Pick a protocol based on speed, size, and compatibility needs.

Integration with Other Systems

PLCs connect with other systems to make work easier. Examples include:

SCADA: PLCs send live data to SCADA for remote monitoring.

HMI: HMIs show PLC data, making machines easy to control.

ERP: PLCs share production info with ERP to manage resources.

Robotics: PLCs work with robots for tasks like welding or packing.

Benefits of Communication and Integration

Good communication makes manufacturing better. Here’s why:

Benefit | Description |

|---|---|

Improved Coordination | Helps systems work together, cutting errors and delays. |

Real-Time Monitoring | Gives instant updates to fix problems fast. |

Data Sharing | Shares accurate info for smarter decisions. |

Scalability | Easy to add new devices as your factory grows. |

Tip: Update your PLC’s firmware often to use the newest protocols.

Real-World Example

Think about a food factory. A PLC reads temperature sensors and sends data to an HMI. You can see and adjust the temperature live. The PLC also shares production info with the ERP system. This helps track stock and plan deliveries. This teamwork keeps everything running well.

By connecting and sharing data, PLCs help factories work better. They make sure all parts of the system work together, improving efficiency.

Benefits of PLC Controllers in Manufacturing

Enhancing Efficiency and Productivity

Faster Production Cycles

A PLC speeds up work by automating repeated tasks. It manages many processes at the same time, reducing delays. For example, in packaging, a PLC controls belts, robots, and labelers together. This teamwork cuts downtime and increases production.

PLCs also make production flexible. You can quickly adjust to changes without big interruptions. Many businesses save money because PLCs simplify operations.

Benefit | Description |

|---|---|

Improved Production Flexibility | Businesses can adapt quickly to changes in production needs. |

Cost Reduction | Streamlined operations lead to lower operational costs. |

Enhanced Agility | PLCs help businesses navigate dynamic environments effectively. |

By automating tasks, PLCs reduce mistakes and keep processes steady. This boosts speed and makes work more efficient.

Optimized Resource Utilization

PLCs help use resources wisely. They track energy, materials, and machine performance. With live data, you can spot problems and fix them fast. For example, a PLC slows motors during low demand to save energy. This reduces waste and saves money.

When linked with systems like SCADA, PLCs give useful insights. These insights help you make smart choices and use resources better.

Improving Accuracy and Reducing Errors

Consistent Product Quality

PLCs ensure products are made with the same high quality. They work with sensors to check things like temperature and pressure. This control keeps production steady. For example, in food factories, PLCs keep cooking temperatures even for better results.

PLCs improve quality by using sensors to monitor key steps.

Live data helps find and fix problems quickly, avoiding bad products.

By automating checks, PLCs lower errors and ensure products meet standards.

Minimizing Human Intervention

Using PLCs means less manual work, which reduces mistakes. Tasks like checking and adjusting settings are done automatically. This improves accuracy and lets workers focus on harder jobs.

PLCs also use feedback loops and data logs to improve monitoring. They connect with Quality Systems to find faults and send alerts. This keeps work smooth and reduces downtime.

Enabling Flexibility and Adaptability

Easy Reprogramming for New Tasks

A big benefit of PLCs is how easy they are to program. You can change their instructions to handle new jobs. For example, in car factories, PLCs can switch to building different models without new machines.

PLCs also connect with other systems, making it easy to add new tools. This keeps work running smoothly during changes.

Adjusting to Changing Production Demands

In today’s fast world, being flexible is important. PLCs monitor processes in real time and give useful insights. These insights help you make quick changes to stay efficient. For example, if demand changes, a PLC can adjust production lines to match.

Aspect | Description |

|---|---|

Programmability | PLCs allow for customizable control logic, enabling quick adjustments to production requirements. |

Integration Capabilities | PLCs can integrate with other automation systems, improving operational efficiency and visibility. |

Real-time Monitoring | Provides insights into process variables, allowing for quick adjustments and optimal conditions. |

Adaptability to Market Changes | Supports rapid reconfiguration to meet changing consumer demands without significant downtime. |

By supporting new tech, PLCs improve data analysis and decision-making. This flexibility keeps your business efficient and ready for change.

Cost-Effectiveness in Operations

Lower Maintenance Costs

Using PLC controllers can help lower maintenance costs in factories. These systems are tough and built to handle hard conditions. Their strong design means fewer breakdowns and repairs. Regular care for your PLCs can prevent big problems and make equipment last longer.

A great feature of PLCs is real-time monitoring. They spot problems early so you can fix them fast. For example, if a motor vibrates oddly, the PLC can warn you to check it. This early action reduces damage and saves money over time.

Here’s how PLCs help save costs:

Benefit | Description |

|---|---|

Preventative care lowers repair and replacement expenses. | |

Increased Productivity | Managing PLCs well boosts overall work efficiency. |

Low Likelihood of Defects | PLCs are made to avoid errors, ensuring smooth operations. |

By cutting maintenance costs, PLCs let you use saved money for other needs. This makes them a smart choice for any factory.

Reduced Downtime

Downtime is costly for factories, stopping work and losing money. PLC controllers help reduce downtime by keeping things running smoothly.

These controllers quickly find and fix problems. For instance, if a conveyor belt stops, the PLC can locate the issue, like a broken sensor. This helps you fix it faster and restart work. PLCs also allow remote monitoring, so you can solve issues without being there.

Another way PLCs cut downtime is by automating tasks. Automation avoids human mistakes that cause delays. PLCs also keep working steadily during long shifts, ensuring everything stays on track.

Tip: Update your PLC software often to keep it reliable and avoid sudden failures.

By reducing downtime, PLCs save money and improve productivity. They help factories meet deadlines and stay competitive in the market.

Applications of Programmable Logic Controllers

Automotive Manufacturing

Assembly Line Automation

In car factories, PLCs help automate assembly lines. They make sure each step works smoothly and quickly. PLCs control robots, conveyor belts, and welding machines to speed up production. They also adjust settings instantly to keep quality high.

PLCs improve product quality and make processes consistent.

Automated checks ensure reliable production results.

Linking with Quality Systems keeps output steady.

Using PLCs reduces mistakes and downtime, saving money. This makes them very useful for modern car factories.

Quality Assurance Systems

PLCs also improve quality checks in car production. They watch important things like pressure, temperature, and torque during assembly. If something goes wrong, the PLC alerts you or stops the process to avoid defects. This ensures every part meets strict rules.

Tip: Pair PLCs with advanced sensors for better accuracy in checks. This helps protect your brand and keep customers happy.

Food and Beverage Production

Packaging and Labeling Automation

In food and drink factories, PLCs make packaging and labeling easier. They connect machines like fillers, labelers, and conveyors to work together. This reduces delays and boosts efficiency.

Evidence Type | Description |

|---|---|

PLCs sync packaging tools to cut downtime and improve speed. | |

Precise Filling and Labeling | Automated systems ensure accurate filling and labeling for better quality. |

Quality Control | Real-time checks stop bad products, protecting your brand and avoiding recalls. |

By automating these tasks, PLCs help keep products safe and meet rules. This is very important in industries needing high precision.

Process and Temperature Control

PLCs are great at managing tasks like mixing, cooking, and cooling. They check things like temperature, pressure, and flow to keep everything consistent. For example, a PLC can keep the right temperature for pasteurizing drinks. This ensures safety and good quality.

Food and drink factories benefit a lot from PLCs. They help meet strict rules while making work faster and better.

Pharmaceutical Industry Applications

Batch Processing Automation

Making medicine needs careful steps and following strict rules. PLCs automate batch processing to make it repeatable and accurate. They follow ISA-88 rules to design and control batches well.

Benefit | Description |

|---|---|

Automation speeds up production while meeting strict rules. | |

Lower Costs | Streamlined processes save money on manufacturing. |

Following GMP Rules | Automation ensures Good Manufacturing Practices with clear records. |

Better Tracking | Batch software improves tracking and keeps batches consistent. |

Faster Product Approval | Electronic records make reviews and approvals quicker. |

Automating batch work reduces human errors and improves product quality. This is key for meeting Good Manufacturing Practices (GMP).

Ensuring Regulatory Compliance

Following rules is very important in medicine-making. PLCs help by keeping detailed batch records and ensuring products stay consistent. They work with software to give live data and reports, making audits easier.

ISA-88 standards ensure products stay consistent and high-quality.

GMP rules need detailed records, which advanced software provides.

Automation cuts human mistakes, making results more reliable.

With PLCs, you can simplify work while meeting strict rules. This boosts efficiency and builds trust with customers and regulators.

Energy and Utilities Sector

Power Plant Automation

Power plants need accurate systems to work well and safely. PLC controllers help by automating tasks like turbine control and energy flow. They use sensor data to adjust operations quickly. For example, a PLC can manage boiler pressure and temperature to keep things safe and efficient.

In oil and gas, each well pad often uses its own PLC. These controllers handle pumps, valves, and sensors to save resources. With Human Machine Interface (HMI) systems, you can control many well pads from one spot. This makes work easier and reduces manual effort.

The need for automation in energy has improved PLC technology. Companies now use PLCs for better control in refining and distribution. These systems boost efficiency and cut costs. With Industry 4.0, PLCs are smarter, offering better data sharing and analysis.

Tip: Update your PLC systems often to stay current with new tech.

Water Treatment Systems

Water treatment plants are key for clean, safe water. PLC controllers automate steps like filtering, adding chemicals, and running pumps. They monitor water quality live and adjust to meet rules. For example, a PLC can fix pH levels by adding the right chemicals.

Sensors and valves in PLC systems help manage resources well. They track water flow, pressure, and temperature to save energy and materials. This lowers waste and cuts costs.

PLCs work for both small and big water plants. You can add new parts as your plant grows without stopping work. This makes it easy to handle more demand while staying efficient.

Key Benefits of PLCs in Water Treatment:

Live monitoring keeps water quality steady.

Automation reduces mistakes and improves reliability.

Expandable systems allow future growth.

By automating water treatment, PLCs help meet rules and provide clean water. They also connect with systems like SCADA to improve efficiency.

Note: Using PLCs in water treatment boosts performance and supports eco-friendly practices.

Real-World Examples of PLC Impact

Case Study: Improving Car Assembly Lines

Car factories need speed and accuracy to work well. PLC controllers help by organizing tasks like welding, painting, and assembly. They make sure robots and conveyor belts work in the right order. This keeps production fast and smooth without delays.

PLCs also check how machines are working. If a robot arm slows down, the PLC notices and alerts the team. Fixing problems early avoids breakdowns and keeps work going. Automating tasks with PLCs reduces mistakes and saves time. They also make it easy to switch to new car models, helping factories stay flexible.

Case Study: Cutting Waste in Food Production

Food factories need to avoid waste while staying accurate. PLC controllers help by automating jobs like mixing, filling, and packing. For example, in a drink factory, a PLC makes sure each bottle gets the right amount of liquid. This stops overfilling and saves materials.

PLCs watch machines in real time. If something breaks, the PLC stops the process right away. This prevents more waste and keeps products good. They also track energy and materials used. By studying this data, factories can find ways to save money and resources.

Tip: Use sensors with PLCs to measure ingredients better and spot bad products.

Case Study: Making Chemical Plants Safer

Chemical plants handle dangerous materials, so safety is very important. PLC controllers improve safety with smart features. For example:

Emergency stops shut machines down fast to protect workers.

Constant checks on safety levels help fix problems quickly.

PLCs also automate safety checks. They watch tank pressure and sound alarms if it gets too high. This helps avoid accidents and follows safety rules. Adding PLCs to chemical systems makes work safer and more efficient.

Note: Keep your PLC software updated to meet the newest safety rules.

The Future of PLC Controllers

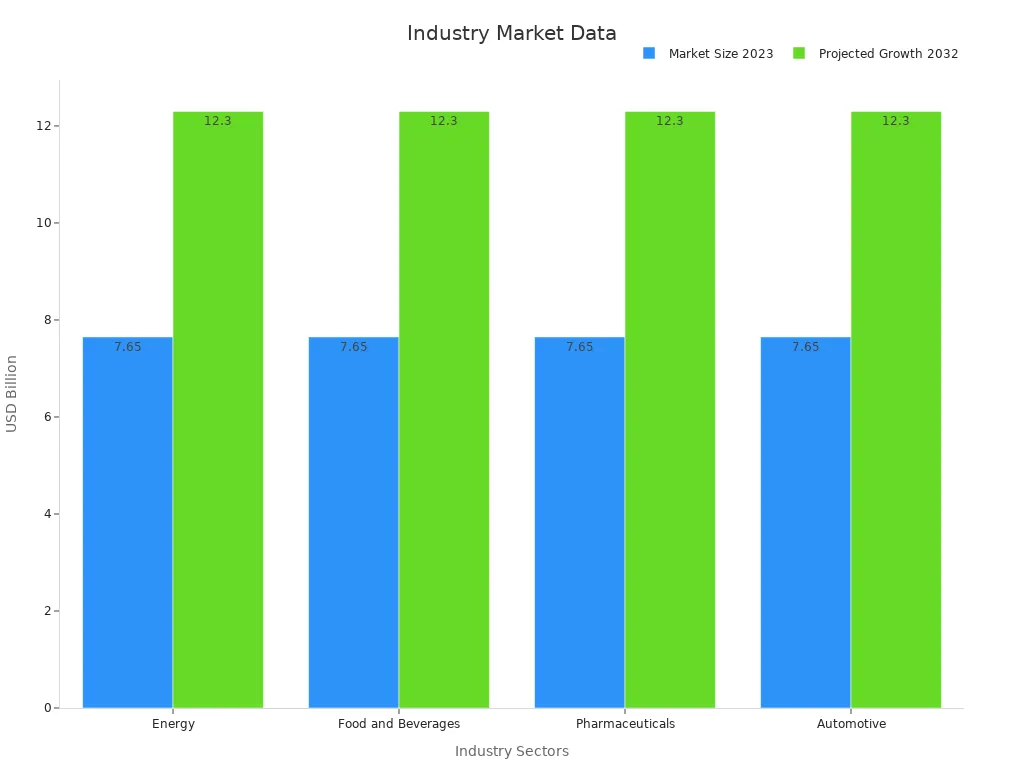

Integration with IoT and Industry 4.0

The future of PLC controllers is about connecting with IoT and Industry 4.0. These technologies make automation smarter and more connected. PLCs now share data instantly, helping with live monitoring and fixing problems early. This keeps factories efficient and ready for changes.

IoT improves work by analyzing data in real time.

Industry 4.0 helps factories use PLCs to boost production.

Better connections allow sharing data and controlling systems remotely.

More industries, like car-making and medicine, are using PLCs. This is growing the market for these controllers. Using these new tools helps businesses stay competitive and improve their processes.

Note: Adding IoT and Industry 4.0 to PLCs makes systems ready for the future.

Advancements in PLC Technology

Edge Computing and Data Analytics

New features in PLCs include edge computing and data analysis. These let PLCs process data nearby instead of sending it to the cloud. Local processing speeds up decisions and saves internet bandwidth.

Edge computing helps PLCs analyze data faster.

Local data handling makes systems work better and quicker.

Smart automation reacts faster and uses resources wisely.

By mixing edge computing with data analysis, PLCs give better insights. This helps factories spot problems early and make smart choices to improve work.

Enhanced Connectivity Features

Modern PLCs have better ways to connect with other devices. Protocols like Ethernet/IP and Modbus make communication reliable. These features let you monitor systems from far away.

Stronger connections help systems work together smoothly.

Remote access lets you fix problems quickly, saving time.

These updates make PLCs flexible and useful for today’s industries.

Emerging Applications in New Industries

PLCs are now used in new areas like healthcare and farming. They work with advanced tools like AI and robots to improve automation. These systems adjust based on live data.

AI helps PLCs predict problems and work smarter.

5G speeds up data sharing for faster operations.

Robots and cameras expand what PLCs can do.

For example, farms use AI-powered PLCs to manage watering systems by checking weather and soil. These changes show how PLCs are helping many industries grow and innovate.

Tip: Learn about new tech to find more ways PLCs can improve your work.

PLC controllers are key tools in today's factories. They make work faster and keep quality steady. These systems use sensors to watch processes live and fix issues early. They also help follow quality rules with tools like SPC. By automating jobs, PLCs cut down on mistakes and ensure reliable results. As technology grows, PLCs will bring more new ideas and better efficiency to factory work.

FAQ

What does a PLC controller do?

A PLC controller helps automate factory tasks. It controls machines, checks sensors, and keeps things running smoothly. This makes work faster and reduces mistakes.

Can small companies use PLCs?

Yes, small companies can benefit from PLCs. They are affordable and help with repetitive tasks. This boosts productivity and lowers human errors in smaller setups.

How do PLCs make products better?

PLCs keep processes like heat and pressure steady. This ensures products are made the same every time. They also adjust quickly to keep quality high.

Are PLCs hard to program?

No, PLCs are easy to program. They use simple languages like ladder logic. Many guides and tools are available to help you learn.

Which industries use PLC controllers?

PLCs are used in car-making, food factories, medicine, and energy. They handle jobs like assembly, packaging, and process control, making them useful in many fields.

How do PLCs stop downtime?

PLCs watch systems live and find problems early. They send warnings or stop machines to avoid damage. This keeps work going without long delays.

Can PLCs work with other systems?

Yes, PLCs connect to systems like SCADA, HMI, and ERP. This helps share data, control devices, and improve teamwork between machines.

How long does a PLC last?

A PLC can work for 10-20 years if cared for well. Regular updates and maintenance keep it reliable and working efficiently.

Tip: Take care of your PLC with regular check-ups to avoid problems and make it last longer.