LVDT Meaning Explained for Beginners

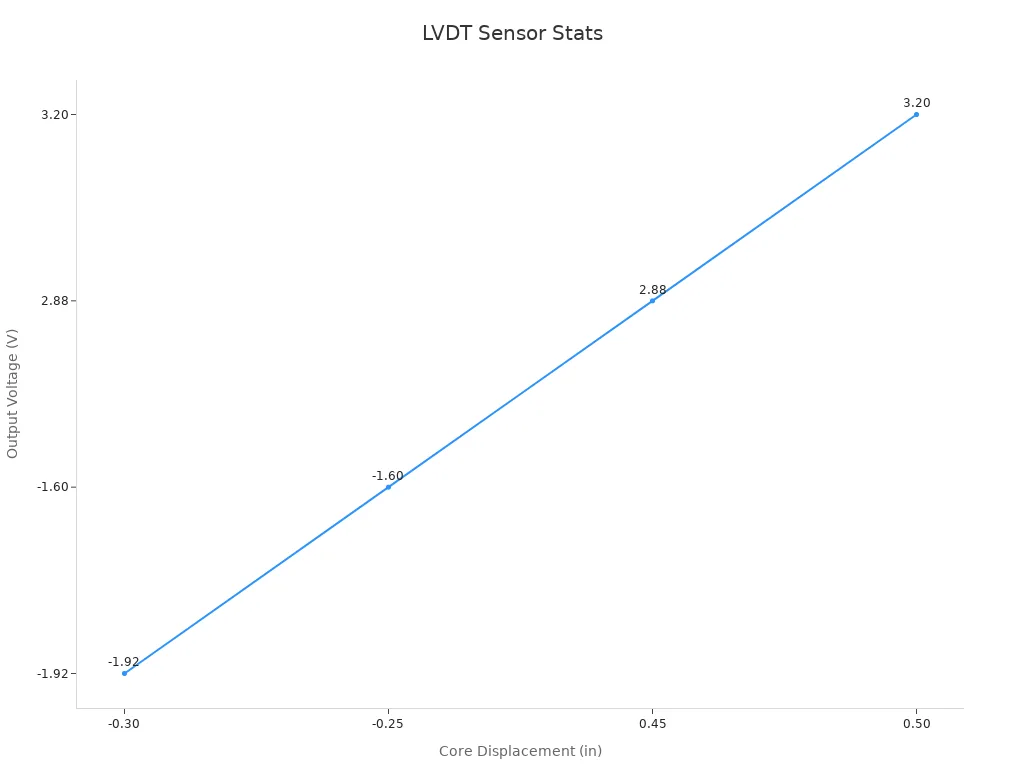

You may ask what LVDT means. LVDT stands for linear variable differential transformer. This device helps you see how far something moves in a straight line. Think of it like a ruler that changes movement into an electric signal. LVDT meaning is easier to understand when you see the output voltage change as the core moves. The chart below shows how the output voltage from an LVDT changes as the core moves. The voltage goes up or down in direct proportion to the core's position. This makes the sensor simple for you to use and easy to understand.

Key Takeaways

LVDT means Linear Variable Differential Transformer. It measures straight-line movement by changing it into an electric signal. The sensor has no friction because its core slides inside coils but does not touch them. This helps the sensor last a long time. LVDTs give very accurate and repeatable measurements. They can even measure tiny movements. There is no mechanical wear. They need AC power to work. They make an AC output voltage that changes with the core’s position. LVDTs are strong and reliable. They work well in tough places like factories, airplanes, and medical devices. They can measure both very small and large movements. This makes them useful in many industries and machines we use every day. LVDTs can be affected by outside magnetic fields. They need shielding or careful placement to stop errors. People use them in industrial automation, aerospace, medical equipment, elevators, cars, and security systems.

LVDT Meaning

Definition of LVDT

You might ask what LVDT means. The LVDT meaning is easy to understand. It is a tool that helps you see how far something moves in a straight line. You can think of it like a special ruler that changes movement into an electric signal. This tool is called a linear displacement sensor. When you move the core inside the LVDT, the tool makes a voltage that matches where the core is. If you move the core more, the voltage changes more. This helps you know exactly how much something has moved.

The technical definition of LVDT is a sensor that uses electromagnetic induction to measure movement. Inside the LVDT, there is a primary coil and two secondary coils. These coils are wrapped around a tube, and a soft iron core slides inside the tube. When you put AC voltage on the primary coil, it makes a magnetic field. This field makes the secondary coils create voltages. If the core is in the middle, the voltages from the two secondary coils cancel out, so the output is zero. When you move the core, the voltages change, and the output shows how far and which way the core moved. This gives you a very exact and repeatable way to measure position.

Note: The LVDT meaning is special because it gives high accuracy, endless resolution, and no friction. You do not have to worry about the tool wearing out fast, since the core does not touch the coils.

You often see LVDTs used when you need to measure movement very carefully. For example, factories use them to check if metal sheets are flat. Engineers use them to test how much something stretches or bends. The LVDT meaning matters in many jobs because it gives results you can trust again and again.

Here is a table that lists some key features of LVDT sensors:

Feature | Details |

|---|---|

Endless, only limited by electronics | |

Mechanical Wear | None, because the core does not touch the coil |

Reliability | High, works well even in tough places |

Life Span | Long, good for many years |

Up to 0.25% | |

Output Signal | AC voltage, changes with movement |

Measurement Range | Small or large movements, depending on the model |

LVDT Full Form

The full form of LVDT is linear variable differential transformer. You can break down the name to help you understand:

Linear: It measures straight-line movement.

Variable: The output changes as the position changes.

Differential: It compares two signals to find the difference.

Transformer: It uses coils and magnetic fields, like a transformer.

When you use an LVDT, you get a tool that can turn movement into an electric signal without any friction. The core moves inside the coils, and the tool tells you exactly where the core is. This makes the LVDT meaning clear: it is a tool that helps you measure movement with great accuracy and trust.

You will find the linear variable differential transformer in many areas, like cars, airplanes, and even medical tools. Its strong build lets it work in hard places, like hot or dusty factories. The LVDT meaning is important because it gives you a simple and good way to measure position in many different situations.

LVDT Working Principle

How LVDT Works

The LVDT is like a ruler that uses electricity and magnets. It measures how much something moves. It works because of electromagnetic induction. When you move the core inside, the magnetic field changes. This makes a new electrical signal. The device has a primary coil and two secondary coils. You send AC power to the primary coil. The core is made of special metal and sits inside the coils. When you push or pull the core, the coils react differently.

The LVDT works by knowing where the core is. If the core is in the middle, the two secondary coils cancel each other. The output is zero. If you move the core to one side, one coil gets more magnetism. The other coil gets less. This makes a difference in voltage. The output voltage shows how far and which way the core moved. This makes the LVDT a good tool for measuring straight-line movement.

Tip: LVDT sensors are great for measuring small or big movements. They are very accurate. The device has no friction, so it lasts a long time.

Signal Conversion

Motion to Electrical Signal

You may wonder how the LVDT changes movement into a signal. The process is simple and follows clear steps:

The LVDT has one primary winding and two secondary windings. The secondary windings are 180° out of phase.

You connect the thing you want to measure to the moving core.

When you move the object, the core moves inside the coils.

If the core is in the center, the voltages in the secondary coils are equal but opposite. The output is zero.

If you move the core, one secondary coil gets more voltage. The other gets less. This makes a difference in voltage.

The size of the output voltage shows how far the core moved. The phase tells you the direction.

For example, with a stroke of ±150 mm and sensitivity of 40 mV/mm, you get up to ±6 V.

The output voltage changes in a straight line with the core’s movement. This helps you measure position very well.

This makes the LVDT an electromechanical passive inductive transducer. You do not need to worry about parts touching each other. The device uses electromagnetic coupling. This makes it last longer and work better.

Inductive Transducer

The LVDT is an inductive transducer. It measures straight-line movement by changing the magnetic link between coils. The core’s position is important for how it works. When you move the core, you change the mutual inductance between the coils. This makes a new voltage in the secondary coils. The difference in these voltages gives you the output signal.

You can measure many things with the LVDT. These include how far the core moves, the size and phase of the output voltage, and the frequency of the AC signal. The output voltage changes in a straight line with the core’s position. You can use electronics to turn this AC output into DC voltage or a digital signal. This makes it easy to use the LVDT with control systems or computers.

Note: The LVDT’s working principle gives you accurate and repeatable results. You can trust it in many places, like factories and airplanes.

LVDT Construction

When you open an LVDT, you see a smart design. It is built to be strong and last a long time. There are three main parts inside. Each part helps turn movement into an electric signal.

Main Components

Primary Coil

The primary coil is in the middle of the LVDT. You send AC power to this coil. The coil makes a magnetic field when it gets power. This field starts the sensing process. The primary coil does not move at all. It stays in one place inside the tube.

Secondary Coils

There are two secondary coils, one on each side. These coils get the magnetic field from the primary coil. The secondary coils are wrapped in opposite ways. When the core moves, each coil gets a different amount of the field. This makes a voltage difference between the two coils. The LVDT uses this voltage to show how far and which way the core moved.

Movable Core

The movable core is a rod made of special iron. You attach the thing you want to measure to this core. When the thing moves, the core slides inside the tube. The core never touches the coils, so there is no rubbing. This helps the LVDT last a very long time. The core changes the magnetic field as it moves. This lets the coils sense where the core is.

Linear Variable Differential Transformer Structure

Think of the LVDT as a tube with three coils around it. A metal rod slides inside the tube. The coils do not touch the rod. This setup helps the sensor work well for many years. The LVDT uses strong metals and tough glue to protect the coils. Magnetic shields stop outside signals from causing problems. The sensor works well in hard places, like wind turbines or factories, because it is built strong.

Imagine the LVDT like a train in a tunnel. The tunnel is the tube with coils, and the train is the core. As the train moves, sensors in the tunnel track its spot without touching it.

Here is a table that shows how the main parts work in real life:

Component/Aspect | Performance Metric / Feature | Application Example |

|---|---|---|

Sensor Accuracy | Flight control, turbine blade monitoring | |

Resolution | Down to 0.1 micrometers | Automotive, medical robotics |

Operating Temperature | -40°C to +125°C | Offshore wind turbines |

Mechanical Life | Unlimited (no friction) | Aerospace, satellites |

Environmental Protection | IP68 (dust and water proof) | Saltwater, harsh environments |

You can count on the LVDT to give good results for many years. The design keeps the signal clear and strong, even in tough places. Engineers use special circuits to block noise and keep the output steady. The LVDT can even remember its spot after losing power, which is important for safety.

If you want to draw a simple picture, sketch a tube with three coils around it and a rod inside. Label the middle coil "Primary," the two side coils "Secondary," and the rod "Movable Core." This picture helps you see how the parts work together.

LVDT Features

High Accuracy

You can count on an LVDT to be very exact. This sensor can measure very tiny movements. It can even sense changes as small as a few millionths of an inch. The device stays accurate for a long time, even in hard places. LVDTs are better than other sensors like potentiometers or magneto-strictive sensors. Potentiometers can wear out and lose their accuracy. LVDTs keep working well for many years. Magneto-strictive sensors might not work as well in rough spots as LVDTs do.

Here is a table that shows how LVDTs do in real tests:

Feature | Specification |

|---|---|

Linearity | |

Thermal Effect on Zero | <0.02% FS/°C |

Thermal Effect on Sensitivity | <0.025% FS/°C |

Response Time | 3 to 5 ms depending on model |

Frequency Response | 50 Hz (-3 dB) |

Resolution | Infinite (detects smallest movement) |

LVDTs have great linearity and almost no change from heat. They react fast, so you can measure quick moves. Many companies pick LVDTs because they are accurate and give the same results every time. You can trust them for jobs that need careful measuring, like testing machines or robots.

LVDTs can measure moves from ±0.010 inches up to ±10 inches or more.

They can find very tiny position changes, only limited by the electronics.

You can use them in tough places, like underwater or in space.

They keep working even with shock, shaking, or very hot or cold temperatures.

Frictionless Operation

You do not have to worry about parts wearing out in an LVDT. The core slides inside the tube but never touches the coils. This means there is no friction, so the sensor lasts a long time. You do not need to change it often, even if you use it every day. No friction also means you get smooth and steady readings. The output does not jump or skip.

Tip: Since nothing rubs or slides, LVDTs work well in places with dust, dirt, or water. You can use them in factories, cars, or medical tools without worrying about them breaking.

No friction also helps the LVDT stay accurate. You do not lose precision as time goes on. The sensor stays good, even after years of use. This makes it a smart pick for important jobs where mistakes are not okay.

Passive Transducer

An LVDT is a passive inductive transducer. You need to give it AC voltage from outside, but it does not make its own power. This passive design makes the LVDT very steady and dependable. You can use it where you need sensors to last a long time with little care.

LVDTs use mutual induction to turn movement into an electric signal.

They have no rubbing or wearing parts, so they last almost forever.

You can use them in hard places, like airplanes, nuclear plants, or oil rigs.

They can handle strong shaking, shock, and very high heat (up to 1200 °F).

The sealed design keeps out water, dust, and chemicals.

Many companies trust LVDTs because of their passive design. You get a sensor that works well in tough places and keeps giving good data. The passive feature also means you can use LVDTs in safety systems, where you need sensors to work every time.

LVDT Advantages and Disadvantages

Advantages

Long Life

An LVDT can last for many years. It is built strong and does not use moving electrical contacts. This means parts do not wear out fast. Many companies use LVDTs for jobs that need sensors to last a long time. They work well in hard places, like factories or airplanes. Since nothing touches inside, the device keeps working after millions of uses.

No Friction

LVDTs do not have friction. The core moves inside the tube but never touches the coils. This gives you smooth and steady readings every time. No friction means the sensor does not wear out quickly. You do not need to replace it often. This also helps you get good results, even after years of use.

Wide Measurement Range

LVDTs can measure very small or very big movements. Some can find changes as tiny as a few millionths of an inch. Others can measure up to many inches, even ±120 inches. This makes LVDTs useful in many jobs, from medical tools to big machines. You can trust them to give you exact results, no matter how much something moves.

Tip: LVDTs work well in tough places. They can handle heat, shaking, water, and dust.

Here is a table that shows the main good and bad points of LVDT sensors:

Aspect | Advantages | Disadvantages |

|---|---|---|

Linearity | High linearity gives great accuracy and a clear input-output link. | N/A |

Resolution | High resolution lets you see very tiny movements. | N/A |

Temperature Sensitivity | Low sensitivity means it works well in different conditions. | N/A |

Operation | No contact inside, so it lasts longer and does not wear out. | N/A |

Durability | Strong build means long life and high trust. | N/A |

Measurement Range | Can measure from very small to very large moves, good for many uses. | N/A |

Vibration Sensitivity | N/A | Outside shaking can cause noise in the readings. |

Electromagnetic Interference | N/A | Outside magnetic fields can mess up the sensor, so shielding is needed. |

Cost | N/A | Costs more at first than some other sensors. |

Size and Weight | N/A | Bigger size and weight can be a problem in small spaces. |

Signal Conditioning | N/A | Needs extra electronics to use the AC output, which makes things more complex. |

Disadvantages

Sensitive to Magnetic Fields

You need to be careful with magnetic fields near an LVDT. The sensor uses a magnetic core and coils to work. If it is close to motors or big wires, outside magnetic fields can cause mistakes. Even small changes in the field can make the sensor give the wrong spot. These mistakes can be as big as hundreds of micrometers. This is a big deal if you need very exact results. Most guides do not warn you about this, so you should plan for shields or careful placement. Some new LVDTs use special materials or shields to help, but you should always check your setup.

Requires AC Supply

LVDTs need AC power to work. You cannot use a simple battery or DC power. The sensor gives an AC signal, so you need extra electronics to change it to a signal you can use. This makes the system harder and can cost more. You may also need to protect the electronics from noise. If you want a simple setup, this can be a problem.

Note: LVDTs can also be affected by shaking and changes in temperature. You might need shields or special circuits to keep your readings right.

LVDTs have many good points, like long life, no friction, and a wide range. But you also need to think about their problems, like being sensitive to magnetic fields and needing AC power. By knowing both the good and bad sides, you can decide if an LVDT is right for your job.

LVDT Applications

Industrial Automation

Factories and plants use the linear variable differential transformer a lot. This sensor helps machines know where parts are. It makes sure things move the right way. In power plants, LVDTs check turbine valve positions. This feedback helps the plant work better and saves money. Gas turbines use LVDTs to watch for shell growth and bearing shaking. This helps you find problems early and fix them before things break.

In the press and dye industry, LVDTs help control metal-shaping machines. They stop the machines if something is wrong. This keeps workers safe and parts good. Oil and gas companies use small LVDTs in drilling tools. These sensors measure borehole size deep underground. They work even when it is hot and under pressure. You can trust these sensors because they last long and work in hard places.

LVDTs help factories work better and save money.

They work in heat, shaking, and even in harsh places.

New LVDTs use better materials and electronics, so they are more reliable.

More companies use LVDTs in automation because they are accurate and work in tough places. Reports show these sensors help with control and safety.

Aerospace

You find LVDTs in planes, rockets, and satellites. These sensors measure how far parts move. This is very important for flight safety. For example, LVDTs check where landing gear pistons are. They also help control flaps and rudders on planes. In jet engines, rotary types called RVDTs measure how much thrust levers turn.

Aerospace companies trust LVDTs because they give exact readings. The sensors work even when the plane shakes or flies high. Some LVDTs work from -40 to 85°C and up to 70,000 feet. You can use them with many control systems. Software makes setup easy.

LVDTs help keep planes safe by giving quick feedback.

They work in cold, heat, and strong shaking.

You can use them in many parts of a plane, like engines or wings.

Companies like National Instruments make special data tools for LVDTs. These help you get fast and correct data during flight tests.

Medical Devices

You also see LVDTs in hospital machines. Hospitals use these sensors in equipment that must measure movement carefully. For example, LVDTs help control patient beds and surgical robots. They make sure beds move smoothly and stop at the right spot. In MRI and CT scanners, LVDTs help move the table with great accuracy.

Doctors and nurses trust LVDTs because they give steady results. The sensors do not wear out fast, so you do not need to replace them often. This saves hospitals time and money. You find LVDTs in devices that must work quietly and without friction. This is important in medical places.

LVDTs help make medical machines safer and more dependable.

They give doctors control for careful tasks.

You can trust these sensors for long use in hospitals.

LVDT use in medical devices grows as technology gets better. You see them in more machines each year, helping patient care improve.

Everyday Uses

You might think LVDTs only belong in factories or airplanes. You actually find them in many places around you. These sensors help make your daily life easier and safer, even if you do not see them.

1. Elevators and Lifts

When you ride an elevator, you want it to stop at the right floor. LVDTs help control the position of the elevator car. The sensor checks how far the car moves. The system uses this information to stop the elevator smoothly and safely.

2. Home Appliances

Some washing machines and dishwashers use LVDTs. The sensor checks the position of doors or trays. If the door is not closed, the machine will not start. This keeps you safe and protects the machine from damage.

3. Car Safety and Comfort

Modern cars use LVDTs in many ways. You find them in automatic gear shifters, brake systems, and even in seat position controls. The sensor helps the car know if a seat is in the right place or if a brake pedal moves correctly. This makes your ride safer and more comfortable.

4. Robotics and Toys

Some smart toys and home robots use LVDTs to sense movement. The sensor helps a robot arm know where it is. This lets the robot pick up objects or move in the right direction.

5. Security Systems

You see LVDTs in automatic doors and gates. The sensor checks if a door is open or closed. The system uses this information to lock doors or sound an alarm if something is wrong.

Tip: LVDTs work quietly in the background. You may not notice them, but they help many machines work better and keep you safe.

Here is a table that shows some everyday uses of LVDTs:

Everyday Item | How LVDT Helps |

|---|---|

Elevator | Stops at the right floor |

Washing Machine | Checks if door is closed |

Car Seat | Adjusts seat position |

Automatic Door | Senses open or closed state |

Robot Toy | Moves arms or wheels |

You can see that LVDTs are not just for big machines. They help in small ways that matter every day. The next time you use an elevator or open an automatic door, remember that a tiny sensor might be working to make your life easier.

You have learned that an LVDT gives very exact results. It can measure the same thing over and over. If the core moves 0.5 inches, the output is 3.2 V. This shows the sensor is both accurate and steady. LVDTs can last for many years, even in hot or cold places. They are more dependable than lots of other sensors.

You can find LVDTs in factories, planes, and medical robots.

New ideas like IoT and making things smaller help LVDTs work in more places.

Keep learning about sensors such as the LVDT. Being curious can help you find cool things in technology! 🚀

FAQ

What does LVDT stand for?

LVDT stands for Linear Variable Differential Transformer. You use it to measure straight-line movement and turn that movement into an electrical signal.

How does an LVDT measure movement?

You move a metal core inside the LVDT. The sensor changes this movement into a voltage. The voltage tells you how far and in which direction the core moved.

Why do LVDTs last so long?

You get long life from an LVDT because the core never touches the coils. No friction means less wear and tear. The sensor keeps working for many years.

Where can you use an LVDT?

You can use LVDTs in factories, airplanes, cars, and even medical devices. They work well in places that need accurate and reliable position measurements.

Does an LVDT need power to work?

Yes, you must supply AC power to the LVDT. The sensor uses this power to create the magnetic field needed for measuring movement.

Can LVDTs measure very small movements?

Yes! LVDTs can detect tiny changes in position, even as small as a few micrometers. You get very high accuracy with this sensor.

What problems can affect LVDT readings?

Strong magnetic fields or electrical noise can cause errors. You should use shielding or place the sensor away from large motors to get the best results.

How do you read the output from an LVDT?

You connect the LVDT to special electronics that change the AC output into a DC or digital signal. This makes it easy for you to read and use the data.

See Also

A Clear Guide To Inverting Versus Non-Inverting Amplifiers

Key Elements To Know About Voltage Regulator Modules

Exploring Backlight Methods Used In LCD And LED Screens

Basic Principles And Guide To Electrostatic Discharge Explained