Understanding Intake and Exhaust Camshaft Sensors

Intake and exhaust camshaft sensors are important for modern engines. These sensors check the camshaft's position and speed. This helps control the timing of valve movements. The intake camshaft sensor manages the intake valves, which let air into the engine. The exhaust camshaft sensor controls the exhaust valves, helping with emissions.

New car technology has made these sensors very important. With more fuel-efficient and electric cars, these sensors are key. Better sensor technology improves engine performance and lowers emissions. This makes them a must-have for today’s vehicles.

Key Takeaways

Camshaft sensors are important for how the engine works. They track the camshaft's position and speed to manage valve timing.

Check your camshaft sensors often to avoid engine problems. Finding issues early can save money on repairs.

Bad camshaft sensors can waste fuel and cause more pollution. Replacing them can boost engine performance by up to 15%.

Signs of a bad camshaft sensor include rough idling, misfires, and the check engine light turning on.

The intake camshaft sensor controls air coming in, while the exhaust camshaft sensor handles gases going out. Both help the engine run smoothly.

Use an OBD-II scanner to find camshaft sensor problems. Codes like P0340 show sensor trouble.

Pick OEM camshaft sensors for better quality. Cheaper parts might break faster and cause more problems.

Clean and check camshaft sensors regularly to make them last longer.

What Is a Camshaft Sensor?

Role in Engine Operation

The camshaft sensor is very important for your car's engine. It checks the camshaft's position and speed to time the valves. This timing helps control fuel injection and ignition. Without it, the engine would not work well.

Modern engines use camshaft sensors to adjust valve timing for speed and load. This makes the engine stronger and saves fuel. In Variable Valve Timing (VVT) systems, it works with the crankshaft sensor to keep things in sync.

Tip: Check your camshaft sensor often to avoid engine problems.

How It Works

The camshaft sensor uses special technology to find the camshaft's position. One method is the Hall Effect. This happens when a magnetic field creates a voltage in a conductor. In your car, the camshaft's magnet makes this field, and the sensor reads the voltage to know the position.

The sensor sends this data to the Engine Control Module (ECM). The ECM uses it to adjust fuel injection and ignition timing. This keeps the engine running smoothly and efficiently.

Aspect | Description |

|---|---|

Function | Tracks the camshaft's position to time the valves correctly. |

Relation to ECU | Matches camshaft data with crank sensor data for better timing, especially in VVT engines. |

Impact on Performance | Improves valve timing based on speed and load, boosting power and saving fuel. |

Why Accurate Camshaft Sensor Data Matters

Good camshaft sensor data is key to keeping your engine healthy. If the sensor gives wrong readings, the ECM can't control fuel and ignition properly. This can make the engine weak, shaky, or even fail.

Studies show that bad sensor data hurts engine performance. Fixing sensor problems early can stop big repairs later. This keeps your car running its best.

Note: If your engine feels slow or rough, the camshaft sensor might be broken. Fixing it early can save money and time.

The Intake Camshaft Sensor

Function and Purpose

The intake camshaft sensor helps your engine work properly. It checks the camshaft's position and speed to control intake valves. These valves let air into the engine for fuel burning. The sensor sends data to the Engine Control Module (ECM) for timing fuel and ignition.

If the sensor gives wrong readings, the engine may struggle. Bad readings can lower fuel efficiency and increase emissions. Studies show faulty sensors can cut fuel economy by 5-10%. Replacing the sensor can improve efficiency and reduce emissions by up to 15%.

Tip: Check your intake camshaft sensor often to avoid engine problems.

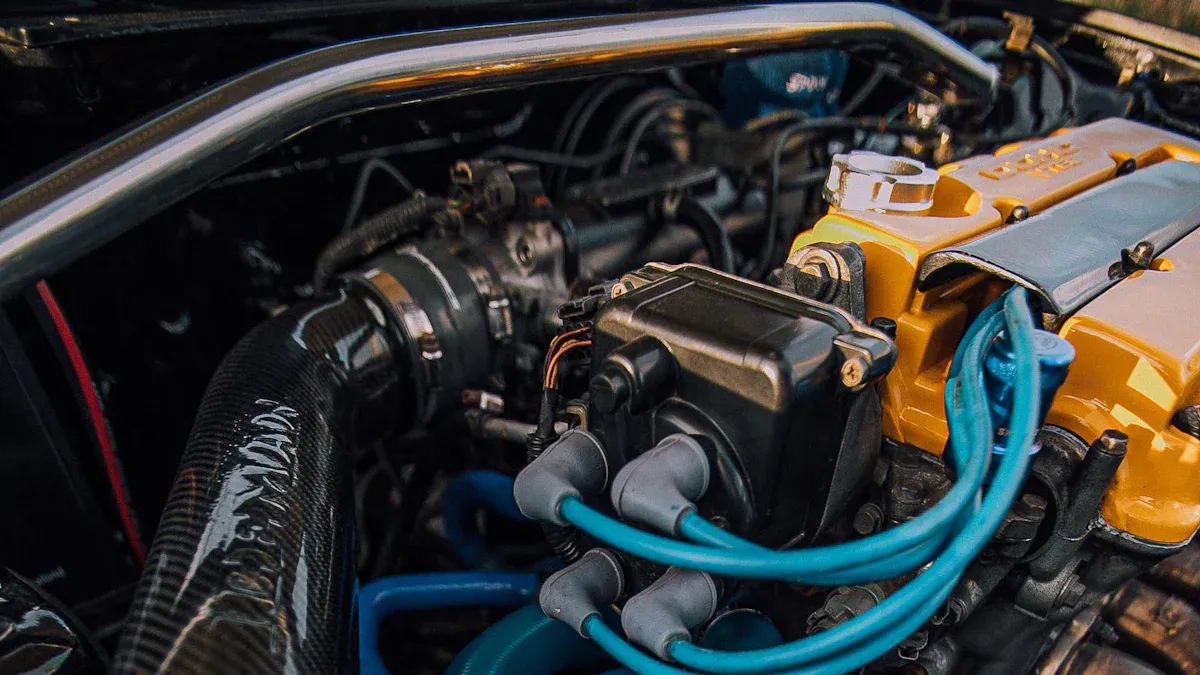

Location in the Engine

The intake camshaft sensor is near the cylinder head or timing cover. Its spot depends on the engine's design. Inline engines usually have it close to the camshaft or cylinder head. V-shaped or boxer engines may have it in different places.

The sensor is placed to track the camshaft's movement accurately. This helps the ECM adjust valve timing for smooth engine operation.

Note: If you don’t know where the sensor is, check your manual or ask a mechanic.

Impact on Engine Performance

A working intake camshaft sensor makes your engine run better. It improves fuel timing, lowers emissions, and boosts power. The ECM uses the sensor to adjust valves based on speed and load. This leads to better fuel burning and engine performance.

A broken sensor can cause problems like rough idling or stalling. Studies show bad timing can lower fuel efficiency by 12% and raise emissions by 15%. Disconnecting parts like the intake manifold pressure sensor can cut power by 28.17 kW.

Fixing the intake camshaft sensor keeps your engine efficient. Solve sensor issues early to save money and avoid bigger problems.

Common Signs of Failure

When the intake camshaft sensor starts failing, your car shows problems. Spotting these issues early can save money on repairs. Below are common signs to look for:

1. Check Engine Light Turns On

The check engine light is often the first warning. Wrong data from the camshaft sensor makes the ECM detect errors. This causes the dashboard warning light to turn on.

Tip: Use an OBD-II scanner to find camshaft error codes.

2. Engine Misfires or Stalls

A bad camshaft sensor messes up valve timing. This can make the engine misfire or stall suddenly. You may notice the engine struggling, especially at slow speeds.

3. Poor Fuel Efficiency

Wrong camshaft data affects how fuel is burned. This wastes fuel and lowers your car's mileage. If you visit the gas station more often, the sensor might be faulty.

4. Rough Idling

A broken camshaft sensor can make the engine run unevenly. You might feel shaking or hear strange sounds while idling. This happens because the ECM can't adjust valve timing correctly.

5. Difficulty Starting the Engine

If the camshaft sensor stops working, the ECM loses key data. Without knowing the camshaft position, the engine may not start at all.

Symptom | Possible Cause |

|---|---|

Check Engine Light | Wrong camshaft data sent to ECM. |

Engine Misfires/Stalls | Valve timing disrupted by sensor failure. |

Poor Fuel Efficiency | Bad camshaft readings cause inefficient fuel burning. |

Rough Idling | ECM struggles with timing, causing uneven engine operation. |

Difficulty Starting | ECM lacks camshaft data, stopping ignition. |

Note: These signs don’t always mean the camshaft sensor is broken. Other engine parts can cause similar problems.

What Should You Do?

If you notice these problems, act fast. Use a diagnostic tool to check the issue. Replace the camshaft sensor if needed. Regular checks can stop sensor failure and keep your car running well.

The Exhaust Camshaft Sensor

Function and Purpose

The exhaust camshaft sensor helps your car's engine work well. It checks the exhaust camshaft's position and speed. This lets the ECM adjust timing for the exhaust valves. These valves release gases after fuel burns in the engine. Without this sensor, the ECM can't time the valves correctly, which hurts engine performance.

The sensor sends accurate data to the ECM for better combustion. This boosts fuel efficiency and lowers harmful emissions. If the sensor breaks, you might notice misfires, rough idling, or worse gas mileage. These problems show how important the sensor is for keeping the engine healthy.

Benefits of the exhaust camshaft sensor:

Helps the engine run better with correct timing.

Saves fuel by improving combustion.

Cuts emissions by controlling exhaust valve timing.

Tip: If your car misfires or idles roughly, check the exhaust camshaft sensor.

Location in the Engine

The exhaust camshaft sensor is near the exhaust camshaft. Its spot depends on your car’s engine design. Inline engines usually have it near the cylinder head or timing cover. V-shaped engines may place it on the side of the engine block near the exhaust camshaft.

The sensor is placed to track the camshaft’s movement accurately. This helps the ECM adjust exhaust valve timing. If you don’t know where it is, check your car manual or ask a mechanic.

Note: Heat and vibrations can wear out the sensor over time. Regular checks can stop sudden failures.

Role in Exhaust Valve Timing

The exhaust camshaft sensor controls when exhaust valves open and close. It works with the ECM to release gases at the right time. This keeps the engine running smoothly and efficiently.

In engines with VVT systems, the sensor is even more important. The ECM uses its data to adjust valve timing based on driving needs. This saves fuel and increases power.

How the sensor helps valve timing:

Manages valve overlap for better fuel burning.

Works with the camshaft actuator to fine-tune timing.

Keeps VVT systems running smoothly for top performance.

If the sensor breaks, the ECM can't time the valves properly. This leads to bad combustion, less power, and more emissions. Fixing sensor problems early can prevent bigger engine issues.

Reminder: A broken exhaust camshaft sensor can mess up timing. Replace it quickly to avoid expensive repairs.

Symptoms of Malfunction

When the exhaust camshaft sensor stops working, your car shows problems. Spotting these early can save money and keep your car running well. Here are common signs of a bad exhaust camshaft sensor:

Engine Misfires: Bad sensor data messes up fuel timing. This makes the engine misfire and lose power.

Poor Fuel Economy: A broken sensor burns fuel poorly. This makes your car use more gas.

Rough Idling: Wrong sensor readings cause uneven idling. You might feel shaking or hear odd sounds when stopped.

Difficulty Starting the Engine: Weak signals from the sensor make starting hard. Sometimes, the engine won’t start at all.

Jerking or Stalling While Driving: Mixed-up signals can cause sudden power loss. This makes the car jerk or stall.

Tip: If you see these signs, use a scanner to check for sensor errors. Fixing the problem quickly can stop bigger issues.

Why These Symptoms Occur

The exhaust camshaft sensor is key to your engine’s work. It tells the Engine Control Module (ECM) the camshaft’s position and speed. The ECM uses this to time the exhaust valves. If the sensor fails, the ECM gets bad or no data. This throws off fuel injection, ignition, and valve timing.

For example, wrong sensor data can make the ECM open and close valves at the wrong time. This causes poor combustion, wasting fuel and raising emissions. Over time, this can harm other engine parts and lead to costly repairs.

What You Should Do

If you think the exhaust camshaft sensor is bad, act fast. Use an OBD-II scanner to find error codes like P0340 or P0365. If the sensor is faulty, replace it to fix your engine. Regular checks can catch problems early and save money.

Reminder: Ignoring sensor issues can damage your engine. Fixing them early avoids bigger costs later.

Symptom | Likely Cause |

|---|---|

Engine Misfires | Bad fuel timing from wrong sensor data. |

Poor Fuel Economy | Fuel burns poorly due to sensor errors. |

Rough Idling | Wrong air-fuel mix and ignition timing. |

Difficulty Starting | Weak or wrong signals from the sensor. |

Jerking/Stalling | Mixed signals disrupt engine power. |

By knowing these signs and their causes, you can fix problems early and keep your car in good shape.

Key Differences Between Intake and Exhaust Camshaft Sensors

Function and Role

The intake and exhaust camshaft sensors have different jobs in your engine. The intake camshaft sensor tracks the intake camshaft's position and speed. This helps the Engine Control Module (ECM) control when the intake valves open. These valves let air into the engine for burning fuel. Correct timing improves fuel use and engine power.

The exhaust camshaft sensor, however, focuses on the exhaust camshaft. It sends data to the ECM about the exhaust camshaft's position and speed. This helps the ECM decide when to open and close the exhaust valves. These valves release gases after burning fuel, keeping the engine smooth and cutting emissions.

In engines with Variable Valve Timing (VVT), both sensors work together. The intake sensor manages air intake, while the exhaust sensor controls gas release. Together, they boost fuel efficiency, engine power, and reduce emissions.

Tip: Knowing what each camshaft sensor does can help you fix engine problems faster.

Physical Location

The intake and exhaust camshaft sensors are placed in different spots. The intake camshaft sensor is near the intake camshaft, often on the cylinder head or timing cover. This location helps it track the camshaft's movement for accurate valve control.

The exhaust camshaft sensor is near the exhaust camshaft. It’s usually on the cylinder head or engine block. This placement lets it monitor the exhaust camshaft's position and speed, helping the ECM time the exhaust valves.

Sensor placement affects how well the engine works. For example:

Camshaft and crankshaft sensors need to be on the camshaft or crankshaft for correct timing.

Oxygen sensors must be near the exhaust to check emissions and fuel use.

Coolant and air intake sensors rely on their spots for fast and accurate readings.

These examples show how sensor location impacts engine adjustments. Checking sensors regularly can stop problems caused by wear or misalignment.

Note: If you don’t know where your camshaft sensors are, check your car manual or ask a mechanic.

Impact on Engine Performance

The intake and exhaust camshaft sensors greatly affect how your engine runs. The intake camshaft sensor ensures the intake valves open and close at the right time. This improves air intake, fuel burning, and engine efficiency. A broken intake sensor can cause bad fuel use, rough idling, or misfires.

The exhaust camshaft sensor controls when the exhaust valves open and close. Proper timing helps gases leave the engine smoothly, lowering emissions and keeping the engine steady. A faulty exhaust sensor can increase emissions, lower power, and make starting hard.

Both sensors keep air intake and gas release balanced. In VVT engines, they adjust valve timing based on driving needs. This improves power, fuel use, and overall performance.

Reminder: Fixing camshaft sensor problems early can protect your engine and make it last longer.

Diagnostic Challenges

Finding problems with camshaft sensors can be tough. These sensors are key to your engine's performance, but figuring out what's wrong often needs careful checks and the right tools. Knowing the challenges can help you handle the process better.

1. Intermittent Sensor Failures

Sometimes, a camshaft sensor works fine, then stops suddenly. This makes it hard to find the issue. You might notice rough idling or misfires, but these problems can vanish before you diagnose them.

Tip: Use an OBD-II scanner to find stored error codes. Even if symptoms go away, the scanner can confirm if the camshaft sensor is causing the problem.

2. Similar Symptoms from Other Components

Other engine parts can cause the same issues as a bad camshaft sensor. For example, a faulty crankshaft sensor or ignition coil can also lead to misfires or stalling. This makes it tricky to know if the camshaft sensor is the real problem.

To avoid mistakes, test related parts like the crankshaft sensor and ignition system. Check wiring connections too. This ensures you don’t replace a working camshaft sensor by accident.

3. Electrical and Wiring Issues

The camshaft sensor sends data to the Engine Control Module (ECM) through wires. Damaged wires, loose plugs, or rust can mess up this connection. Even if the sensor is fine, these problems can send wrong data to the ECM.

Look at the wires and plugs for damage or wear. Use a multimeter to check if the circuit works properly. Fixing these issues might solve the problem without needing a new sensor.

4. Environmental Factors

Heat, oil leaks, and vibrations can harm the camshaft sensor. Over time, these things can make the sensor fail. For example, engine heat can damage its parts, and oil leaks can make it less accurate.

Regular maintenance can stop these problems. Keep the engine clean and check for leaks during inspections. Replace worn gaskets and seals to protect the sensor.

5. Difficulty Accessing the Sensor

Sometimes, the camshaft sensor is hard to reach. In some engines, it’s easy to access, but in others, it’s buried under parts. This makes it tricky to inspect or replace without removing other components.

Note: Check your car manual to find the camshaft sensor. If it’s hard to reach, ask a mechanic for help.

6. Misinterpretation of Error Codes

Error codes from the ECM can be confusing. A code for a camshaft sensor issue might actually mean a problem with the crankshaft sensor or timing chain. Misreading these codes can lead to unnecessary repairs.

To avoid this, match error codes with your car’s symptoms. Careful diagnostics can help you find the real problem.

7. Impact of Aftermarket Sensors

Aftermarket camshaft sensors can cause extra problems. They might not be as good as original equipment manufacturer (OEM) parts. This can make them fail faster or send wrong data to the ECM.

When replacing a sensor, choose OEM parts if possible. They are made for your engine and work more reliably.

By knowing these challenges, you can handle camshaft sensor problems with more confidence. Using the right tools, doing regular maintenance, and paying attention to details can make fixing these issues easier.

Common Issues and Symptoms of Camshaft Sensor Problems

General Symptoms of Sensor Failure

When a camshaft sensor starts to fail, your car shows warning signs. These signs can be similar to other engine problems, making it hard to diagnose. Knowing these symptoms early can help you avoid expensive repairs.

Common Warning Signs:

Check Engine Light Turns On: The light comes on when the sensor sends wrong data to the Engine Control Module (ECM).

Rough Idling: A bad sensor messes up valve timing, causing the engine to shake or make strange noises when idle.

Low Engine Power: Incorrect sensor data can make the engine weaker, especially when speeding up.

Hard to Start: Weak signals from the sensor can make starting the engine difficult.

Heat Problems: Sensors exposed to too much heat may stop working at times, causing random engine issues.

Diagnostic Methods:

Symptoms | How to Check |

|---|---|

Test sensor resistance with a digital multimeter | |

Rough Idling | Use a dual-trace oscilloscope to check signal quality |

Low Power | Look for physical damage or oil on the sensor |

Error Codes (DTCs) | Check for electrical issues affecting sensor signals |

Heat-Related Failures | Use a heat gun or tap test to find intermittent problems |

Tip: Use an OBD-II scanner to find error codes like P0340 or P0341. These codes often point to camshaft sensor issues.

Sensor Signal Patterns:

Hall effect sensors create square-shaped, digital signals.

Variable reluctance sensors make wave-like, curved signals.

Using a lab scope to check these patterns can confirm if the sensor is working properly.

Specific Issues with Intake Camshaft Sensors

The intake camshaft sensor helps control how air enters the engine. If this sensor fails, the engine may struggle to get enough air, causing performance problems.

Symptoms of Intake Sensor Failure:

Engine Misfires: Wrong sensor data causes fuel injection problems, leading to misfires.

Bad Gas Mileage: Faulty readings waste fuel, making you use more gas.

Rough Idling: The ECM can’t adjust valve timing, making the engine run unevenly.

Hard to Start: Without correct camshaft data, the engine might not start.

Diagnostic Challenges:

Problems with the intake camshaft sensor can seem like issues with other parts, like the crankshaft sensor. To confirm the problem, check the sensor’s wires and plugs for damage or rust.

Note: Cleaning around the sensor regularly can stop oil and dirt buildup, which helps prevent failure.

Specific Issues with Exhaust Camshaft Sensors

The exhaust camshaft sensor controls when gases leave the engine. If this sensor breaks, it can cause performance and emission problems.

Symptoms of Exhaust Sensor Failure:

Symptom | What It Means |

|---|---|

Irregular Signal Pattern | Shows the sensor or its wires might be damaged. |

Engine Misfires | Happens when wrong data causes bad fuel injection timing. |

Poor Gas Mileage | Caused by incorrect fuel burning due to sensor failure. |

Rough Idling | Results from wrong air-fuel mix and ignition timing. |

Hard to Start | Weak signals make it tough to start the engine. |

Jerking or Stalling | Mixed-up signals can cause sudden power loss while driving. |

Why These Symptoms Happen:

The exhaust camshaft sensor tells the ECM the camshaft’s position and speed. If the sensor fails, the ECM gets bad data, messing up valve timing. This leads to poor fuel burning, more emissions, and less engine power.

Reminder: Replace a broken exhaust camshaft sensor quickly to avoid damaging your engine further.

Diagnostic Tips:

Use a dual-trace oscilloscope to check the sensor’s signal. Strange patterns often mean the sensor or its wires are damaged. Look for physical damage, oil leaks, or heat wear on the sensor.

Fixing these problems early keeps your engine running well and saves money on repairs.

Diagnosing and Fixing Sensor Problems

Fixing camshaft sensor issues may seem hard, but it’s doable. A clear plan can save you time, money, and stress. Follow these simple steps to solve the problem.

Step 1: Spot the Symptoms

Watch how your car acts. Signs of a bad camshaft sensor include rough idling, misfires, poor gas mileage, or trouble starting. Look for warning lights like the check engine light. These clues often mean sensor trouble.

Tip: Use an OBD-II scanner to find error codes. Codes like P0340 or P0341 often show sensor problems.

Step 2: Check the Sensor and Wires

Look at the sensor and nearby parts. Check for dirt, rust, or loose wires. Broken wires or plugs can mess up signals, even if the sensor works. Cleaning and tightening connections might fix the issue.

Inspection Tips:

Make sure all connections are tight and clean.

Keep the sensor away from too much heat or shaking.

Step 3: Test the Sensor

Testing shows if the sensor works. Use a multimeter to check its resistance. Compare the numbers to your car’s guide. If the readings are wrong, the sensor likely needs replacing.

Note: An oscilloscope gives a detailed look at the sensor’s signal. It can spot unusual patterns that show failure.

Step 4: Replace the Sensor

If the sensor is bad, replace it with a good-quality one. Pick a sensor that matches your car’s original part. Cheap parts can cause more problems later.

Why Quality Counts:

Good sensors send accurate data to the ECM.

Reliable parts last longer and prevent future issues.

Step 5: Reset the ECM

After replacing the sensor, reset the Engine Control Module (ECM). This clears error codes and helps the ECM adjust to the new sensor. Disconnect the battery for a few minutes or use an OBD-II scanner to reset it.

Step 6: Watch for Changes

After repairs, check if your car runs better. Make sure the problems are gone. If not, check other parts like the crankshaft sensor or timing chain.

Reminder: Regular care can stop sensor problems. Clean the engine, fix oil leaks, and check wires during routine maintenance.

Why Steps Help

A step-by-step plan fixes the real problem. Studies show regular checks and good parts lower sensor failures. Following these tips keeps your engine running well and avoids costly repairs.

Diagnostic Step | Key Action |

|---|---|

Spot Symptoms | Notice engine issues and check warning lights. |

Check Sensor and Wires | Look for dirt, rust, or loose wires. |

Test the Sensor | Use tools to confirm if the sensor works. |

Replace if Needed | Install a high-quality sensor that fits your car. |

Reset the ECM | Clear codes and let the system adjust. |

Watch for Changes | Make sure the engine runs smoothly after repairs. |

By following these steps, you can fix camshaft sensor problems easily. Regular care and attention keep your car in great shape.

Knowing how intake and exhaust camshaft sensors differ is important. The intake sensor handles air entering the engine. The exhaust sensor controls gases leaving the engine. Both sensors help with valve timing for smooth running and saving fuel.

Tip: Check these sensors often to avoid engine problems. Finding issues early saves money and keeps your car working well.

Taking care of these sensors protects your engine and helps it last longer. Fix problems quickly to keep your car in great condition.

FAQ

1. What does a camshaft sensor do?

A camshaft sensor watches the camshaft's position and speed. It sends this information to the Engine Control Module (ECM). The ECM uses it to adjust valve timing for better engine performance and fuel use.

2. How can I tell if my camshaft sensor is failing?

Look for problems like rough idling, misfires, or bad gas mileage. Starting the car might be hard, and the check engine light could turn on. Use an OBD-II scanner to find sensor error codes.

3. Can I drive with a faulty camshaft sensor?

Driving with a broken camshaft sensor can hurt your engine. It messes up valve timing, causing misfires, wasted fuel, and more emissions. Fix it soon to avoid expensive repairs.

4. Where is the camshaft sensor located?

The intake camshaft sensor is near the cylinder head or timing cover. The exhaust camshaft sensor is close to the exhaust camshaft, often on the engine block or cylinder head.

5. How do I test a camshaft sensor?

Use a multimeter to measure the sensor's resistance. Compare the numbers to your car manual. An oscilloscope can also check if the sensor signals are correct.

6. What error codes indicate camshaft sensor problems?

Common codes include P0340 and P0341. These codes mean there’s a problem with the sensor or its wires.

7. Should I use OEM or aftermarket camshaft sensors?

OEM sensors work better and last longer. Aftermarket sensors might break faster or send wrong data. Choose OEM parts for reliable performance.

8. How often should I check my camshaft sensors?

Check camshaft sensors during regular maintenance. Look for dirt, oil leaks, or damaged wires. Regular checks stop sudden problems and keep your engine running well.

See Also

Exploring the Functionality of a Camshaft Position Sensor

The Importance of Crank Angle Sensors in Automobiles

Maintaining Mass Air Flow Sensors for Engine Efficiency