The Role of Cutting-Edge Technology in Chipset Manufacturing

Technology has changed how chip designs are made smaller and better, including how to make chipset more efficiently. New methods help create chips for phones, computers, and more. In 2023, about 1 trillion chips were sold worldwide. That’s over 100 chips for every person on Earth. AI tools make chips work faster and use less energy. They cut power use by 15-20% and boost efficiency by 25%. These changes meet high demand and help improve AI, IoT, and 5G tech.

Key Takeaways

New technology is changing how chipsets are made, making devices faster and better.

Semiconductors are important for gadgets like phones and medical tools.

Chipsets join many chips to boost speed and connection in devices.

Special methods like EUV lithography make smaller, stronger chips that save energy.

AI and machines help make chips faster, with fewer mistakes, and better quality.

Companies care about the planet and use clean energy and recycling to cut waste.

New materials like graphene and nanotubes can make chips work better and look different.

Future tech like quantum computing and AI will change chip design, creating smarter devices.

Why Semiconductors Matter in Today's Technology

Semiconductors: The Heart of Electronics

Used in gadgets, cars, and healthcare tools.

Semiconductors are key to the devices you use every day. They power phones, laptops, and even smartwatches. In cars, they help with self-driving, electric systems, and safety tools. In healthcare, they run imaging machines, health trackers, and robotic surgery tools. These uses show how semiconductors affect many parts of life.

The semiconductor industry is growing fast because of high-tech demand. AI and IoT are pushing this growth forward. For example, by 2030, the market may pass $1 trillion, growing 13.8% yearly. This shows how semiconductors are crucial for our digital world.

Helping devices connect and compute better.

Semiconductors make today’s connected world possible. They power circuits in phones, laptops, and routers, helping them communicate. These circuits process data so you can stream, browse, and chat easily.

Semiconductors also improve computing power. They act like switches, controlling electricity in devices. This helps computers work with 0s and 1s, the basics of digital data. Without semiconductors, fast and multitasking devices wouldn’t exist.

Why Chipsets Are Key to Tech Progress

Smaller size, better performance.

Chipsets, groups of circuits, make devices smaller and stronger. New semiconductor tech shrinks chips, fitting more parts into tiny spaces. This makes devices faster and saves energy. For example, power electronics are growing 14.24% yearly, thanks to green energy and electric cars.

Boosting AI, IoT, and 5G.

Chipsets are vital for AI, IoT, and 5G tech. AI in 5G chipsets improves speed and data handling. By 2025, 40% of 5G chipsets will have AI. Also, 30% of phones will support mmWave 5G by 2024. These upgrades help machines talk to each other, key for industrial IoT. Chipsets are shaping the future of technology and innovation.

How to Make Chipset: The Fabrication Process

Key Steps in Semiconductor Manufacturing

Designing and testing integrated circuits.

Making a chipset starts with designing its circuits. Engineers use special software to plan how the chip will work. They test the design to check for any problems. This step helps fix issues before making the actual chip. It saves time and ensures the chip works properly.

Turning designs into real chips.

After the design is ready, it moves to production. The digital plan is printed onto silicon wafers. Advanced tools create millions of tiny switches called transistors on each wafer. These switches help the chip process information. This step turns the virtual design into a real product.

Advanced Lithography Techniques

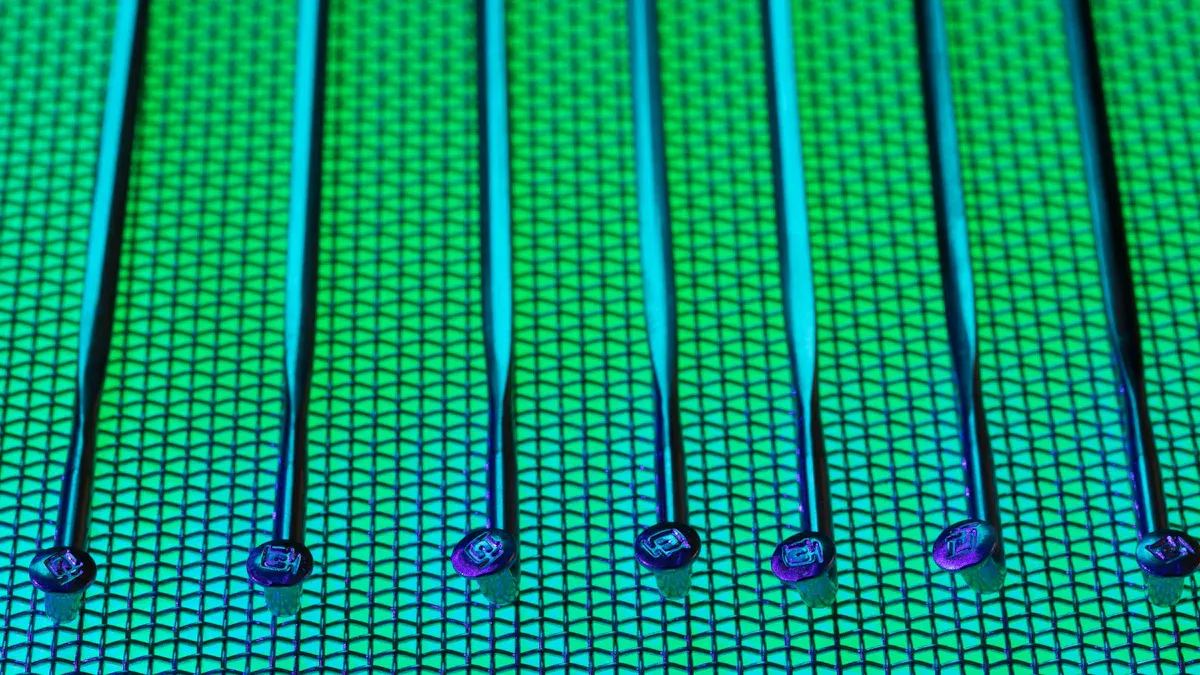

Using light to create patterns.

Photolithography is an important part of making chips. It uses light to draw patterns on the wafer. These patterns show where the circuits and transistors will go. A special material called photoresist reacts to the light to form these patterns. This step ensures the chip is made accurately.

Making patterns smaller with EUV.

EUV lithography uses very short light waves to make tiny patterns. This lets manufacturers add more transistors to a chip. More transistors mean better performance and less energy use. EUV has changed how chips are made, allowing for super small and precise designs.

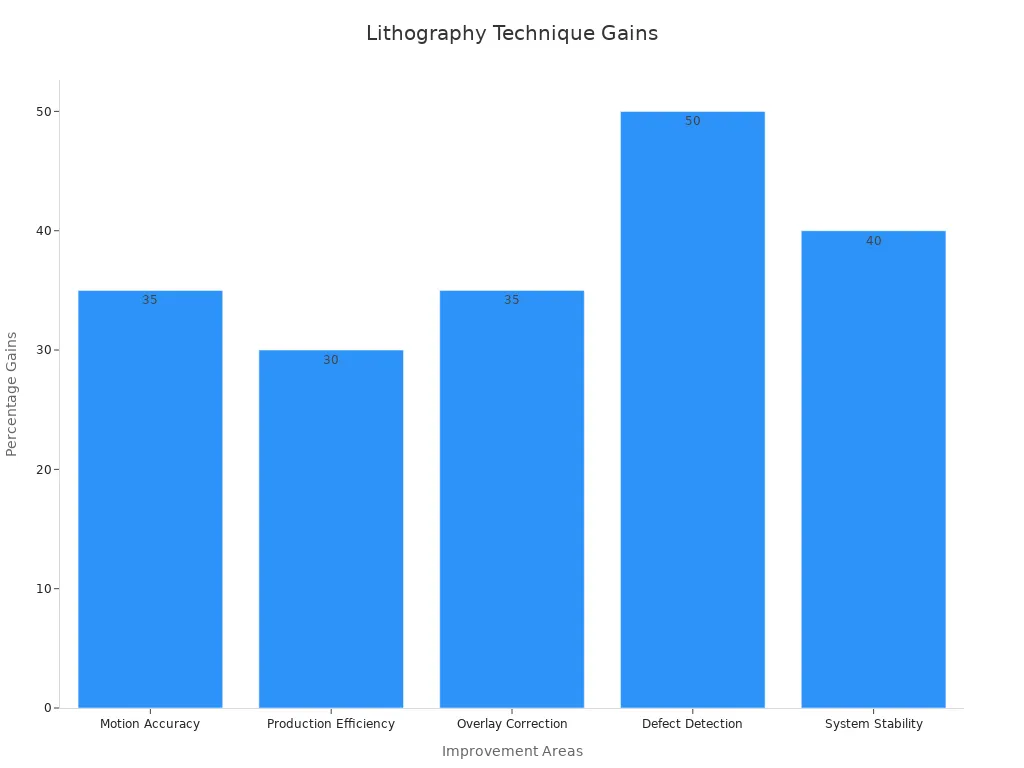

Improvement Area | Percentage Gain |

|---|---|

Motion Accuracy | 35% |

Production Efficiency | 30% |

Overlay Correction | 35% |

Defect Detection | 50% |

System Stability | 40% |

Cleanroom Standards and Precision Tools

Keeping the environment clean.

Chip factories use cleanrooms to avoid contamination. These rooms control air, temperature, and humidity. Even a tiny dust particle can ruin a chip. Cleanrooms have filters to keep the air clean and protect the wafers.

Benefit | Description |

|---|---|

Controlled factors like temperature and humidity enhance the manufacturing environment. | |

Reduce product contamination rate | Filtration of particulate matter leads to lower contamination levels in products. |

Improve product quality | Maintaining stable environmental conditions results in higher quality products. |

Reduce production costs | Lower damage rates and improved quality contribute to decreased overall production costs. |

Tools for super small details.

Special tools are needed to make chips with tiny details. These include electron microscopes and advanced machines for lithography. Regular checks keep these tools working perfectly. Such precision is necessary to meet modern tech needs.

Gross Die Yield: Counts usable chips from a wafer to measure efficiency.

Process Optimization: Improves steps like etching, deposition, and material use.

Equipment Calibration: Ensures tools stay accurate for better chip-making results.

Defect Management: Finds and fixes defects to improve chip quality and yield.

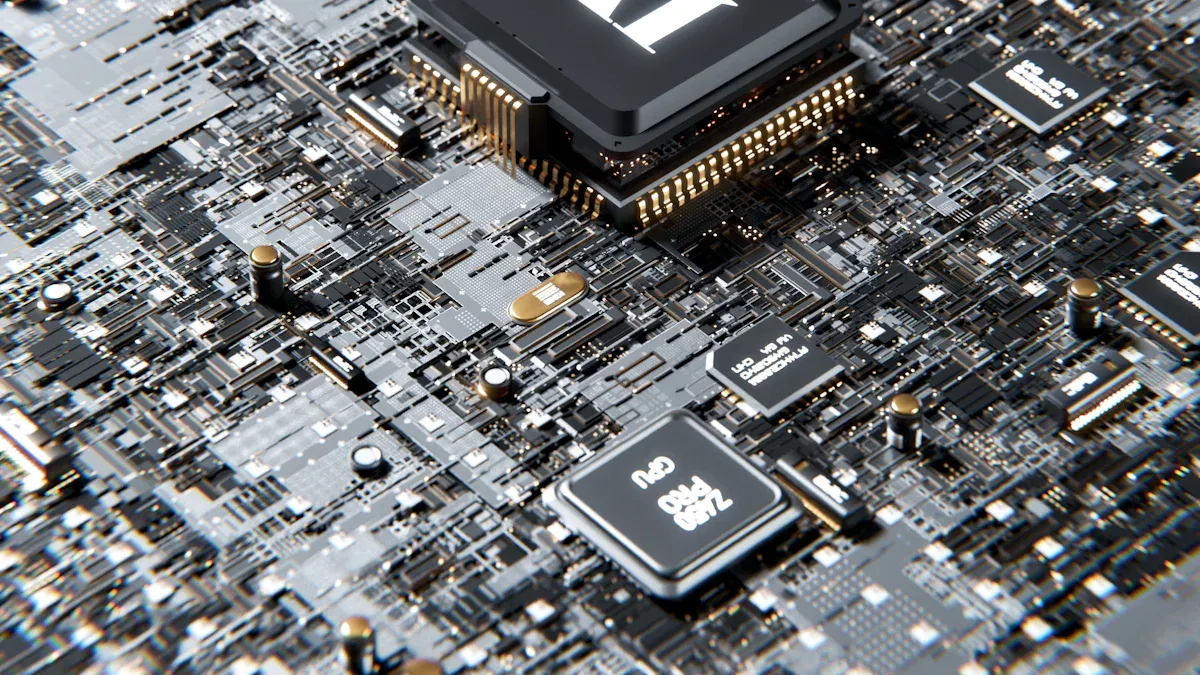

Assembly and Packaging Processes

Cutting wafers into chips

After the silicon wafer is ready, it gets cut into chips. This step is called wafer dicing. Tools like diamond saws or lasers slice the wafer into tiny pieces. Each piece becomes a single chip. Think of it like cutting a pizza into equal slices.

Next, the chips are prepared for assembly. They are placed on carriers that connect them to circuits. This lets the chip work with other parts in a device. Engineers use methods like wire bonding or flip-chip bonding to attach the chips. These techniques make strong connections and keep the chip stable.

Tip: Accuracy matters during dicing and assembly. Small mistakes can ruin the chip's function.

Protecting chips with packaging

Packaging keeps chips safe and helps them work better. It protects them from moisture, dust, and damage. Without packaging, chips would break easily. Materials like plastic, ceramic, or metal are used to cover the chip based on its purpose.

Modern packaging does more than protect. It also improves how chips perform. For example, Fan-Out Wafer-Level Packaging (FOWLP) makes chips smaller and stronger. Other methods, like 3D stacking and System-in-Package (SiP), combine multiple chips into one package. This saves space and boosts performance, perfect for phones and IoT devices.

Performance Feature | Explanation |

|---|---|

Advanced Packaging Methods | FOWLP increases efficiency and reduces size. |

3D Stacking and SiP | Combines chips to save space and improve power. |

Specialized Chips | Designed for AI and IoT needs. |

Better Connections | Strong links between chips improve performance. |

Smaller Chip Sizes | Compact designs fit modern devices. |

Reliability Improvements | Protects chips from damage and contamination. |

Lower Costs | Efficient designs reduce production expenses. |

These packaging methods help chips meet today's tech needs. Whether it's a phone, smart home gadget, or electric car, packaging ensures chips work well and last long.

Note: Packaging isn’t just for protection. It also helps make chips smaller and more efficient for advanced technology.

Advanced Chip Manufacturing Materials and Techniques

Cutting-Edge Materials in Semiconductor Manufacturing

Silicon and emerging alternatives like gallium nitride

Silicon has been used in chips for many years. It is common and works well for electronics. But as devices need to be faster, new materials like gallium nitride (GaN) are being explored. GaN moves electricity faster and handles higher voltages. This makes it great for power devices and 5G networks. Using these new materials helps make chips better and more efficient.

Material Type | Growth Rate (CAGR) | Importance in Semiconductor Manufacturing |

|---|---|---|

Low-k Dielectrics | 10% | Helps lower energy use and speed up signals in devices. |

EUV Photoresists | 15%+ | Needed for making smaller, stronger, and energy-saving chips. |

Compound Semiconductors | High demand for 5G and electric cars makes them essential. | |

Semiconductor Materials Market | $80 billion by 2030 | Shows how new materials are driving the future of chip-making. |

These materials not only improve performance but also meet the needs of AI, IoT, and other advanced technologies.

High-k and low-k materials for efficiency

High-k and low-k materials are key to better chips. High-k materials help control electricity in transistors, stopping energy waste. Low-k materials reduce delays in signals, making devices faster. These materials are crucial for creating smaller, quicker, and energy-saving chips to keep up with modern tech demands.

Innovations in Circuit Design

3D circuits and stacking technologies

Old chip designs are hitting their limits. To fix this, engineers now stack chips in layers. This 3D stacking saves space and boosts performance. It also increases storage without losing speed.

3D stacking makes chips faster and uses less energy.

The market for 3D stacking may grow 20.8% yearly from 2025 to 2033.

These designs help create smaller, stronger devices.

With 3D stacking, companies can make compact chips for phones and IoT gadgets.

Photonic curing applications

Photonic curing is a new way to improve circuits. It uses strong light to quickly heat and harden materials. This allows for flexible and lightweight designs, perfect for wearables and bendable electronics. Photonic curing speeds up production and opens doors to creative chip designs.

Tip: Flexible circuits made with photonic curing are great for future tech like wearable devices.

Automation and AI in Manufacturing

Machine learning for defect detection

AI and automation are changing how chips are made. Machine learning finds defects during production by studying large amounts of data. This reduces waste and improves chip quality. For example, Samsung uses AI to catch defects, making better chips and reducing errors.

Area of Improvement | Description | Example Company |

|---|---|---|

Predictive Maintenance | Predicts machine problems to avoid delays. | GlobalFoundries |

Yield Improvement | Finds issues early, improving chip output by 15%. | N/A |

Operational Efficiency | Speeds up work and reduces human mistakes. | N/A |

Defect Detection | Spots flaws better, lowering defective products. | Samsung |

Supply Chain Management | Plans inventory and demand more accurately. | Applied Materials |

AI ensures chip-making stays fast and cost-effective, even as designs get more complex.

Automated systems for process optimization

Automation makes chip production smoother and faster. Machines track every step, from adding materials to final assembly. They use real-time data to fix problems and improve processes. This precision is vital for making many chips at once.

Automation also helps manage supplies. It predicts material needs and avoids shortages. This is important because supply chain issues can slow down production.

Note: Automation not only boosts efficiency but also cuts waste and saves energy, helping the environment.

Challenges in Semiconductor Chip Manufacturing

Precision and Scalability Issues

Achieving nanometer-scale accuracy

Making chips smaller is very hard. At 3nm, transistor gates are just a few atoms thick. Even tiny mistakes can cause problems like slower performance or more power use. Shrinking chips to 1nm makes this even harder. Current tools, like EUV lithography, struggle to make such small designs. New materials and methods are needed to fix these issues. Without precise designs, modern technology won’t work as well.

Scaling production to meet global demand

The world needs more chips than factories can make. Events like COVID-19 and natural disasters have slowed production. This has caused shortages in cars and electronics. Chips are made in many countries, which adds delays. Factories focus on making chips for phones, leaving other industries behind. Fixing these problems is key to making enough chips for everyone.

Environmental and Sustainability Concerns

Energy consumption in fabrication processes

Making chips uses a lot of energy. Most of it comes from fossil fuels, not renewable sources. In 2021, chip factories used enough electricity to power 25 million people for a year. By 2030, energy use will grow even more, causing more pollution. Factories need to switch to cleaner energy and better methods to help the environment.

Waste management and sustainable practices

Chip-making creates a lot of waste. Recycling and better designs can reduce this waste. For example, chips can be made easier to recycle when they’re no longer useful. Using less material and energy also saves money. Systems like deposit-return programs help collect old chips for recycling. These steps make chip-making greener and more cost-effective.

Supply Chain and Geopolitical Challenges

Dependence on rare materials and global suppliers

Chip factories need rare materials and lots of water. Many factories are in places with water shortages. By 2030, almost half of these factories will face big water problems. Rare materials like gallium and cobalt are also hard to get. Political issues make it even harder to find these resources.

Impact of trade restrictions and geopolitical tensions

Political fights between countries, like the U.S. and China, hurt chip production. Tariffs and export rules make it harder for Chinese companies to get advanced tools. This raises costs and slows progress. Some countries are trying to make chips locally, but this has challenges too. Planning ahead is important to deal with these global issues.

Future Trends in Advanced Chip Manufacturing

Quantum Effects in Semiconductor Design

Using quantum mechanics for faster chips

Quantum mechanics is changing how chips work. It uses special effects to make single-molecule transistors much better. These transistors can switch over 10,000 times faster and stay stable for 100,000 cycles. This method saves energy and improves how devices perform. It’s a big step toward making chips quicker and more reliable.

Quantum computing will also change chip design. In 10 to 15 years, it might be as fast as today’s AI. Governments and companies are investing in this technology. Combining light-based systems with silicon could solve current problems. Quantum computing will play a huge role in the future of chips.

Helping quantum computers solve problems

Quantum computers can handle tough problems quickly. They process data much faster than regular computers. This helps improve chip designs and manufacturing steps. For example, quantum mechanics can make transistors and circuits more efficient. These improvements are important for industries like AI, healthcare, and green energy, where speed matters.

New Materials and Techniques

Graphene and nanotubes for better chips

Graphene and carbon nanotubes (CNTs) are changing chip-making. These materials are super strong, fast, and efficient. For example:

Carrier Mobility: Graphene reaches 230,000 cm² V⁻¹ s⁻¹; CNTs hit ~80,000 cm² V⁻¹ s⁻¹.

Electric Current Capacity: Both handle over 10⁹ A cm⁻².

Thermal Conductivity: Graphene reaches 5,300 W m⁻¹ K⁻¹; CNTs go up to 3,500 W m⁻¹ K⁻¹.

Mechanical Strength: Tensile strength is 130 GPa, making them very durable.

These features make them perfect for smaller, faster, and energy-saving chips. Their flexibility also allows for cool designs like bendable gadgets and wearable tech.

New ideas in molecular electronics

Molecular electronics is another exciting area. Scientists have made molecules that carry electricity with almost no energy loss. These molecules improve how charges move, creating new ways to build devices. By mixing these molecules with current chip tech, we can make super-sensitive sensors and other advanced tools. This pushes chips to do more than ever before.

AI and Machine Learning in Manufacturing

Smarter processes with AI

AI is making chip production smarter and faster. It finds tiny defects, improving quality. AI also saves energy by optimizing steps during manufacturing. For instance, it adjusts settings to get the best results while using less power. AI even predicts the best materials to reduce waste, making the process greener.

AI for better chip design and testing

AI doesn’t just help make chips—it also designs them. Machine learning studies data to find the best circuit layouts. It tests designs virtually, saving time and money. AI ensures high-quality chips at lower costs. By using AI in every step, companies can make better chips and stay competitive.

Tip: AI tools not only boost efficiency but also keep you ahead in the fast-moving chip industry.

New technologies are changing how chipsets are created. They make devices faster and more efficient. These improvements solve problems like accuracy and environmental impact. The semiconductor industry keeps growing with these changes. Future advancements in AI, quantum computing, and green methods will lead to even better tools. These innovations will improve the technology you use daily in surprising ways.

FAQ

What is a semiconductor, and why is it important?

A semiconductor controls electricity in electronic devices. It powers things like phones, cars, and medical tools. Without it, modern gadgets wouldn’t work. Semiconductors make devices faster, connect better, and save energy.

How are chipsets different from regular chips?

Chipsets are groups of chips that work together. They help device parts communicate smoothly. Regular chips do one job, but chipsets handle multiple tasks. For example, your phone’s chipset manages processing, graphics, and internet.

Why are cleanrooms essential in chip manufacturing?

Cleanrooms stop dust from ruining chips. Even tiny particles can break a chip. These rooms control air, temperature, and humidity to keep chips safe. This ensures high-quality chips are made.

What makes Extreme Ultraviolet (EUV) lithography special?

EUV lithography uses short light waves to make tiny patterns. This helps fit more transistors into smaller chips. It makes chips faster and saves energy, improving device performance.

How does AI improve chip manufacturing?

AI finds defects, predicts machine problems, and improves production steps. It studies data to make better chips with less waste. AI also tests chip designs virtually, saving time and materials.

What are 3D stacking technologies in chip design?

3D stacking places chips on top of each other. This saves space and boosts performance. It adds storage and power without making devices bigger. It’s great for small gadgets like phones and smart devices.

Why is sustainability a challenge in chip production?

Making chips uses lots of energy and water. Most factories use fossil fuels, which harm the planet. Recycling and using clean energy can cut waste and pollution, making chip production greener.

What role do new materials like graphene play in chipmaking?

Graphene is strong, light, and conducts electricity well. It makes chips faster and more energy-efficient. Its flexibility allows for cool designs like bendable gadgets. Graphene is shaping the future of electronics.

Tip: Watch out for graphene-based gadgets—they’re the future of tech!

See Also

Exploring Key Historical Developments in Integrated Circuit Technology

How Integrated Circuits Shape Careers in Today's Technology

Comparing Popular Inverter Chips: Key Differences Explained

The Importance of Dual Inline Packages in PCB Creation

A Comprehensive Guide to ASICs and FPGAs: Uses and Advantages