Exploring How Heat Sinks Power Today’s Electronic Devices

Heat sinks help keep electronics cool and working well. More than half of device problems happen because of too much heat. Heat sinks and other cooling methods can cut these problems in half for every 10 °C drop in chip heat. Laptops, LED lights, and car systems use heat sinks to stay safe. For example, aluminum heat sinks in electric cars and LED lights help batteries last longer and keep lights shining bright. These cooling tools make devices work better and last longer.

Key Takeaways

Heat sinks help keep devices cool by moving heat away. This stops damage and helps devices work better.

Aluminum and copper are used to make heat sinks. Aluminum is light and not expensive. Copper cools better but is heavy and costs more.

Heat sinks use conduction and convection to move heat. Fins and more surface area help spread heat into the air fast.

There are three main types of heat sinks. Passive ones are quiet and easy. Active ones use fans for stronger cooling. Hybrid ones use both ways.

Skived heat sinks have thin fins cut from one metal piece. They cool well in small spaces and save energy.

Good thermal management helps laptops, LED lights, cars, and green energy systems last longer and work better.

New materials like graphene and nanomaterials help heat sinks cool even more. Custom designs fit special device needs.

Heat sinks keep devices from getting too hot. This helps them run faster and last longer.

Heat Sinks Overview

Definition

A heat sink is a tool that takes heat away from electronics. It stops things like processors and batteries from getting too hot. Heat sinks use conduction and convection to move heat into the air. Most heat sinks have a base that touches the hot part. They also have fins that spread out to make more surface area. This shape helps cool things down faster. Many devices, like computers and LED lights, need heat sinks to stay safe.

Purpose

Heat sinks are important for keeping devices cool. They stop sensitive parts from getting too hot. When a device works, it makes heat. If the heat stays inside, the device can slow down or break. Heat sinks move this heat away fast. This helps devices last longer and work better. As electronics get smaller and stronger, cooling becomes more important. New designs, like fluid topology optimization, help heat sinks fit in small spaces. These changes let devices stay cool even when they work hard.

Note: Good heat sinks can cool hotspots by up to 45°C. This big drop helps devices last longer and work better.

Materials

The material of a heat sink changes how well it cools. Different materials move heat in different ways. The most common ones are aluminum and copper. Some new heat sinks use special materials for better cooling.

Aluminum

Aluminum heat sinks are used a lot. They are light, easy to make, and cost less than others. Many laptops and LED lights use aluminum heat sinks because they are not heavy. Aluminum heat sinks do not rust, so they last longer. They also move heat well, so they are good for many devices.

Copper

Copper heat sinks move heat faster than aluminum ones. They are heavier and cost more, but they work better for powerful devices. Gaming computers and some car electronics use copper heat sinks for extra heat. Copper heat sinks keep things cooler and protect important parts. Some heat sinks use both copper and aluminum to balance weight and performance.

Advanced Materials

Some heat sinks use new materials to cool better. Flexible thermal interfaces made from self-assembled boron arsenide help move heat. Metal foams and porous materials also make heat sinks work better. These new materials can lower the hottest temperature and help devices last longer. For example, metal foam in a heat sink can drop the highest temperature by almost 25% and make devices run four times longer. As electronics get smaller, these new materials help keep devices safe.

Material | Weight | Cost | Thermal Conductivity | Common Use Cases |

|---|---|---|---|---|

Aluminum | Light | Low | Good | Laptops, LED lighting |

Copper | Heavy | Higher | Excellent | Gaming PCs, automotive |

Advanced (e.g., boron arsenide, metal foam) | Varies | High | Superior/Customizable | Wearables, high-power chips |

How Heat Sinks Work

Heat Dissipation Principles

Heat sinks protect electronics by moving heat away. They use conduction and convection to do this. Conduction moves heat from the device into the heat sink. Then, convection moves heat from the heat sink into the air. This helps keep the device cool and safe.

Many things affect how well heat sinks work. The material, fin shape, airflow, and how the device runs all matter. Engineers test and change designs using experiments and computers. More airflow means the heat sink cools better. Grooved microchannels can help heat move faster by 28%. Different rib shapes in microchannels work in different ways. Rectangular ribs are best when airflow is low. Elliptical ribs work better when airflow is high. Taller fins help with heat transfer, but only up to a point. If fins get too tall, they stop working as well. Staggered fins in LED systems cool better than straight ones. Hybrid heat sinks can handle more heat and use less energy. Heat pipes with high thermal conductivity keep LED chips safe. Careful design helps heat sinks work better and keep devices cool.

Tip: Lowering thermal resistance helps heat sinks remove more heat. This keeps devices working well.

Thermal Pathways

A heat sink uses thermal pathways to move heat out. The path starts at the hot part of the device. Heat goes through a thermal interface material. This fills tiny gaps and helps contact. Then, heat moves into the heat sink base and spreads through the fins.

Researchers look at these paths to make heat sinks better. Microchannel heat sinks use small grooves to move heat fast. Some designs copy shapes from nature, like snowflakes or squid fins. These shapes help heat move and lower drag. Computer models help test different groove shapes. Semi-pendeloque grooves can balance cooling and airflow. Nanofluids, like silver-water, can help heat move up to 86% faster. Changing microchannel shapes, like using trapezoids or circles, can help heat move up to 80% better. Some designs use vortex generators to stir air and move heat away. These ideas help heat sinks handle more heat and keep resistance low.

Microchannel heat sinks with nature-inspired designs help heat move better.

Nanofluids in microchannels help heat transfer work well.

Good groove shapes and coolants help heat sinks cool better.

Surface Area and Design

The surface area and design decide how well a heat sink cools. More surface area gives more space for heat to leave. Engineers use fins and pins to add area without making the heat sink too big.

Studies show network-structured heat sinks with thin fins can double heat loss compared to thick fins. These network designs are lighter but still cool as well or better. For example, a 22Network structure had the best heat loss. Changing pin-fin patterns also helps a lot. Cylindrical pin-fins in double-cross patterns can make heat transfer up to 328% better than simple patterns. This also raises the Heat Transfer Performance Factor. Smart design choices help heat sinks cool better.

Note: More surface area and smart designs help heat sinks lower resistance and move heat better.

Engineers keep testing new shapes and layouts to find the best mix of size, weight, and cooling. These efforts help devices stay cool, work faster, and last longer.

Types of Heat Sinks

Passive

Passive heat sinks cool devices without moving parts. They use natural convection and conduction to move heat away. The shape and material help spread heat into the air. Aluminum heat sinks are common because they are light and cheap. They also do not rust. Many electronics, like routers and speakers, use passive heat sinks. These heat sinks keep noise low.

Engineers pick passive heat sinks for quiet devices. They work best in things that do not get very hot. The number of fins and the material matter a lot. More fins or metallic foam can help cool better. Some studies show metallic foam with phase change materials works well. It can lower the highest temperature by over 35%. It also helps devices last four times longer. In LED lights, where LEDs sit and the heat sink design matter. Narrow LED layouts need better heat sinks to stop overheating.

Note: Passive heat sinks do not need power or much care. They are a good choice for many small devices.

Active

Active heat sinks use fans or blowers to move air. This forced air removes heat faster than natural convection. Aluminum heat sinks are used a lot in active systems. They are light and move heat well. Active heat sinks are found in gaming computers and servers.

Active heat sinks can handle more heat in small spaces. The fan breaks up the thermal boundary layer. This makes heat move away faster. Studies show active heat sinks cool better than passive ones. This is true when devices work hard for a long time. But fans make noise and need power. They also need cleaning and can break.

Aspect | Passive Heat Sink | Active Heat Sink |

|---|---|---|

Natural convection and conduction, no moving parts | Forced airflow using fans or blowers | |

Cooling Efficiency | Lower, for low to moderate heat loads | Higher, for high heat loads |

Noise Level | Silent | Noisy due to fan operation |

Power Consumption | None | Needs power for fan |

Maintenance | Low (no moving parts) | Higher (fan can fail, needs cleaning) |

Size | Larger for same cooling | More compact possible |

Materials | Aluminum, Copper | Aluminum or Copper |

Applications | Low-power, noise-sensitive devices | High-performance devices (PCs, servers) |

Hybrid

Hybrid heat sinks mix passive and active features. They have a base made from copper or aluminum. Fins help with passive cooling. A fan gives extra airflow when needed. Aluminum heat sinks are important in hybrid systems. They keep weight low and move heat well.

Tests show hybrid heat sinks cool almost as well as copper ones. But they weigh 24% less. Hybrid designs spread heat more evenly. This protects important parts from getting too hot. Many powerful electronics use hybrid heat sinks. Power inverters and advanced LED systems use them to balance cooling, size, and weight.

Tip: Hybrid heat sinks cool well and save space. They are great for modern, high-performance electronics.

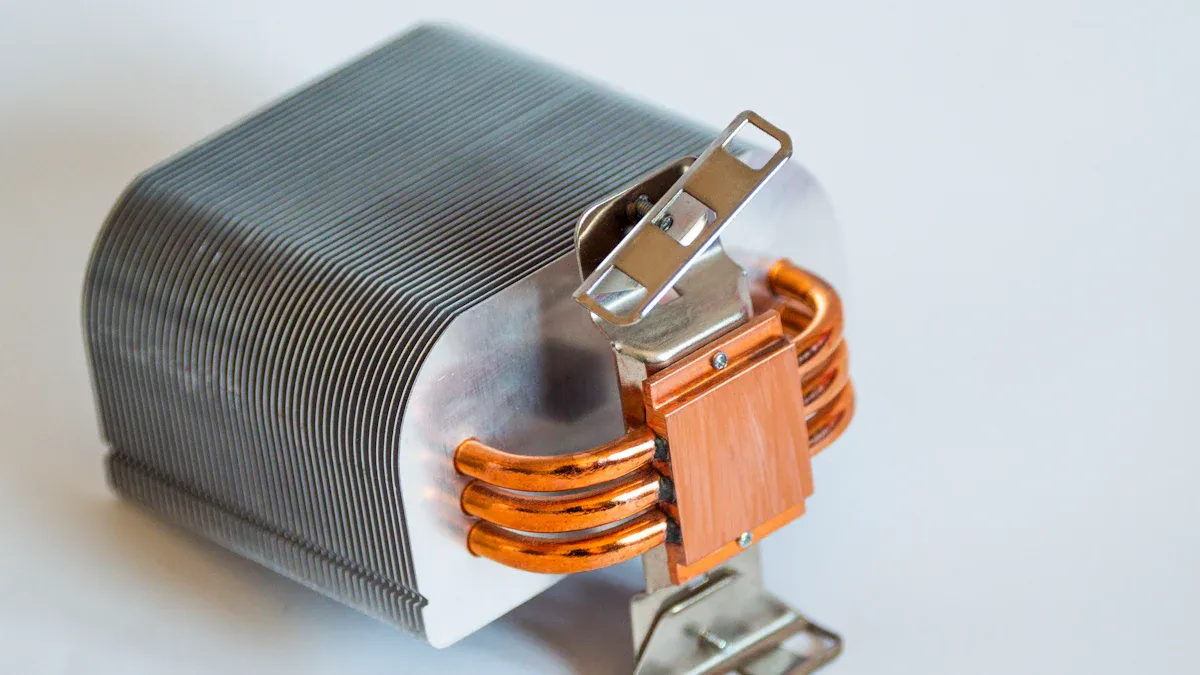

Skived

Skived heat sinks use a special process to create thin, tall fins from a single piece of metal. This method slices the metal and bends it up, making many fins without extra parts. Most skived heat sinks use aluminum because it is light and easy to shape. Some use copper for even better heat movement.

Skived heat sinks stand out for their compact size and strong cooling power. Engineers choose them for devices that need to stay cool but have little space. The thin fins give a large surface area, which helps move heat away quickly. This design keeps electronics safe from overheating.

Skived heat sinks fit well in tight spaces, like inside LED lights or small computers.

The thin fins allow more air to touch the surface, which improves cooling.

Aluminum heat sinks made with skiving cost less and weigh less than many other types.

Skived heat sinks can be made in many shapes and sizes to match different devices.

They work well in power electronics, automotive parts, and processor cooling.

Note: Skived aluminum heat sinks help devices last longer by keeping them cool. Their design also saves energy because they do not need extra fans or bulky parts.

Many companies use skived heat sinks in real products. LED lighting systems use them to keep lights bright and safe. Power electronics in cars and computers rely on skived aluminum heat sinks for steady performance. The ability to customize these heat sinks means each device gets the best cooling for its needs.

Skived heat sinks also offer cost savings. Their strong cooling means devices do not need extra cooling systems. This lowers energy use and keeps devices smaller. Aluminum heat sinks made with skiving resist rust and last a long time, making them a smart choice for many uses.

Thermal Management in Modern Electronics

Importance

Thermal management is very important for modern electronics. Devices like electric vehicles, smartphones, and computers make a lot of heat when used. If this heat stays inside, parts can break or stop working sooner. Good thermal management keeps the temperature steady. This helps devices last longer and work better.

As electronics get smaller and stronger, thermal management becomes more important. The market for thermal management systems was about $12.5 billion in 2023. Experts think it will almost double by 2032. This shows that controlling heat in new devices is very important. Studies show up to half of the energy in electric vehicle motors turns into heat. If cooling is not good, this energy loss can hurt performance and battery life. The table below shows some important facts:

Aspect | Statistic / Finding | Impact / Importance |

|---|---|---|

Energy loss in EV motors | Highlights need for efficient thermal management | |

Fast charging time reduction | Up to 20% reduction with advanced E-Cooling systems | Enables faster charging and reduces performance loss |

Battery performance | Optimal temperature maintenance enhances lifespan | Prevents premature wear and failure |

Note: Keeping devices at the right temperature helps them last longer and work better.

Methods

Engineers use different ways to manage heat in electronics. They pick the best method for each device and how much heat it makes. Some common ways are:

Passive cooling: Devices use heat sinks and natural airflow to move heat away. This works well for devices that do not use much power.

Active cooling: Fans or blowers push air over heat sinks. This helps cool high-power devices faster.

Phase change materials (PCMs): These materials soak up heat as they melt. They help keep the temperature steady when the device works hard.

Thermoelectric coolers (TEC): These use electricity to move heat away from important parts.

Nanofluids and coatings: Engineers add tiny particles to fluids or use special coatings to help heat move better.

Studies show that using thermoelectric coolers with nano-fluid-cooled micro-channel heat sinks lowers surface temperatures in high-power LEDs. In electric vehicles, forced convection cooling keeps battery packs safe. For smartphones, graphene nanosheet coatings help lower device temperatures. Each method helps lower thermal resistance and makes cooling better.

Challenges

Modern electronics have many problems with thermal management. Devices are getting smaller but need to handle more power. This makes it hard to fit enough cooling inside. Engineers must balance thermal resistance, cost, and how easy it is to make each part.

Some main problems are:

Small devices do not have much space for cooling parts.

Materials need to move heat well but also be cheap and easy to shape.

Power use changes fast, so cooling systems must react quickly.

Room temperature and humidity can change how well cooling works.

Testing needs special tools like thermal cameras and computer models.

Engineers use thermal cameras and computer models to find hot spots early. They test devices with thermal cycling to make sure they work in real life. In high-performance computers, better simulations have cut energy use by 30%. In electric vehicles, phase change materials help keep batteries safe. For IoT devices, microchannel cooling lets them work in very hot places.

Tip: Lowering thermal resistance is key to better cooling. Good design and testing help devices stay safe and last longer.

Thermal management technology keeps changing to solve these problems. Engineers look for new materials and smarter designs to meet the needs of modern electronics.

Applications in Modern Electronics

Consumer Devices

Consumer electronics are everywhere in our lives. Things like smartphones, tablets, and smartwatches use heat sinks. Heat sinks protect the inside parts from getting too hot. These devices keep getting smaller and stronger. This means they make more heat in a tiny space. Heat sinks help move this heat away from important parts.

A new copper heat sink design made heat move 60% better. This proves that better heat sink designs really help these devices. Smaller heat sinks also cost less and use less power. New designs lower thermal resistance and pumping power. These changes help devices stay cool and last longer.

Many electronics use aluminum or copper heat sinks. Laptops and gaming consoles need them to keep chips safe. Wireless earbuds and fitness trackers use tiny heat sinks for batteries. Good thermal management means fewer problems and longer life for devices.

Tip: Heat sinks in electronics stop overheating. This keeps devices working well for many years.

Computing

Computers need good cooling to work fast and not break. Heat sinks keep CPUs, GPUs, and memory chips from getting too hot. Engineers use new materials and smart shapes to cool computers better.

Fin thickness changes how well heat moves.

Taller fins give more area but can slow air.

Fin spacing changes how air and heat move.

Computer models help pick the best fin size and space. For example, 0.5 mm thick fins with 1.5 mm space work best for many computers.

Some heat sinks now use graphene and other nanomaterials. These move heat much faster than copper or aluminum. Graphene can reach up to 5000 W/mK in thermal conductivity. This helps computers run cooler and faster.

Studies show new heat sink designs can lower CPU heat by about 50%. They also help lose over 60% more heat. These changes stop computers from crashing or slowing down. Gaming computers and servers use these advanced heat sinks for heavy work.

Note: Better heat sinks in computers protect parts and help them work better.

LED Lighting

LED lighting changed how we light homes and streets. LEDs use less energy and last longer than old bulbs. But they still make heat at the chip and phosphor layers. Heat sinks are very important for keeping LED lights cool.

Most LED bulbs use aluminum heat sinks. These take in and spread heat from the LED chip. This stops the bulb from getting too hot. Good heat sinks help LED lights last longer and shine brighter. They also help save energy.

Studies show heat sinks in LED lighting help both performance and lifespan. Passive heat sinks, heat pipes, and immersion cooling all help move heat away. These ways protect the chip and keep the light steady.

Energy reports say aluminum heat sinks in LED lighting stop overheating. This makes LEDs work better than other lights. New designs also help lower the environmental impact of making heat sinks. As LED lighting grows, better heat sinks will keep lights safe and bright.

Tip: Heat sinks in LED lighting save energy and help bulbs last longer.

Automotive and Aerospace

Heat sinks are important in cars, trucks, planes, and satellites. These vehicles use more electronics now than before. Electronics control engines, batteries, and safety systems. If these parts get too hot, they might stop working. This can cause safety problems.

Reports say cars and planes need better ways to handle heat. New vehicles use smaller and stronger electronics. These make more heat in less space. Heat sinks help move this heat away fast. This keeps everything working well. Engineers use passive, active, and hybrid heat sinks in vehicles. Electric cars use advanced heat sinks for battery packs and power parts. This helps batteries last longer and keeps cars safe.

Aerospace systems also need good cooling. Satellites and planes face very hot and cold temperatures. Special heat sinks, like microchannels and pin fins, spread heat quickly. Skived heat sinks are made from one piece of metal. They fit in small spaces and cool important parts. New ways to make heat sinks make them lighter and cheaper. This is important in planes and satellites where weight matters.

Note: Heat sinks in cars and planes protect important systems. They help keep people safe and make vehicles last longer.

Power and Renewable Energy

Heat sinks help power and renewable energy systems work better. Solar panels, wind turbines, and inverters all get hot when running. Too much heat can lower how much energy they make. It can also make them wear out faster.

Researchers tested different heat sink shapes on solar panels. They found that porous or perforated fins can cool panels by up to 15 °C. This makes the panels work up to 13.7% better. Engineers use computer models to test heat sinks. These tests show that heat sinks help solar panels make more power.

The material of the heat sink matters a lot. Aluminum and carbon heat sinks often work better than copper in power systems. Aluminum and carbon spread heat better in these setups. Passive cooling, like zigzag or perforated fins, also helps. Some designs can make over 7 more watts of power. These changes make renewable energy systems work better and cost less.

Photovoltaic-thermal systems use both active and passive cooling. Heat sinks on thermoelectric generators help move heat away. This makes energy conversion better. Air-cooled aluminum heat sinks are popular because they are cheap and last long. More airflow over heat sinks helps make more power for all materials.

Porous and perforated fins cool solar panels and raise efficiency.

Aluminum and carbon heat sinks are best for making power.

Passive cooling designs make systems more reliable and efficient.

Good airflow and smart designs help renewable systems last longer.

Tip: The right heat sink design in power and renewable energy systems saves energy, lowers costs, and helps equipment last longer.

Innovations in Heat Sinks

Material Advances

New materials have made heat sinks work better. Scientists use nanomaterials like carbon nanotubes and graphene in thermal interface materials. These help heat move much faster. Some heat sinks use graphite. Graphite is light and moves heat well. Nano-structured surfaces give more space for heat to leave. They also help air move around the fins. These changes can make heat transfer up to 300% better. Nano-coatings make surfaces smoother. They also stop dust from sticking.

Researchers mix graphene with phase change materials like paraffin wax. This mix helps heat sinks take in and let out heat faster. Tests show that adding graphene to these materials makes heat sinks work better. At 15 watts, the new design worked 30% better than old ones. At 30 watts, it worked 45% better. These new ideas help devices stay cool and last longer.

Graphite-based heat sinks are light and move heat well.

Nanomaterial TIMs with carbon nanotubes or graphene help heat move.

3D printing and metal injection molding make new shapes that cool better.

Miniaturization

Modern electronics are getting smaller and stronger. This means chips make more heat in less space. Early microchannel heat sinks could handle up to 790 W·cm⁻². Old air-cooling systems could only handle about 100 W·cm⁻². New microelectronic devices can make up to 1500 W·cm⁻². These numbers show why better cooling is needed in small spaces.

Metric | Value | Context |

|---|---|---|

Heat flux from new chips | 1500 W·cm⁻² | More heat in smaller devices |

Air-cooling system limit | ~100 W·cm⁻² | Traditional cooling methods |

MCHS cooling capacity | 790 W·cm⁻² | Early microchannel heat sinks |

Allowed temperature rise | 70 °C | MCHS at 790 W·cm⁻² |

A study found that lowering device temperature by 1 °C can cut failure rates by 4%. This shows why good heat transfer is important in small electronics. Engineers use phase change materials for passive cooling. These materials store a lot of heat and do not need power. But they can be slow to charge and discharge. New designs add nanomaterials to help them work faster.

Customization

Every device needs its own way to cool down. Engineers now make custom heat sinks for each job. For example, a high-brightness LED needed a special copper heat pipe. This design spread heat and stopped hotspots. Another device needed more cooling late in the design. Engineers added custom fins to the heat sink. They did not have to change the whole board. This saved time and money.

Custom heat sinks use copper, aluminum, or vapor chambers.

Engineers use software to test designs before making them.

New shapes like wavy or sinusoidal fins give more area and cool better.

Customization helps in medical devices, aerospace, and electric vehicles.

High-performance computers need better cooling for processors. Custom pin-fin heat sinks for GPUs can lower chip temperatures. This stops slowdowns. In aerospace, heat pipes keep electronics safe in tough places. These custom solutions help devices work better and last longer.

Note: Custom heat sinks help engineers fix special cooling problems for each device. This keeps every part safe and working well.

Importance of Heat Sinks

Preventing Overheating

Heat sinks help stop electronics from getting too hot. When a device works, it makes heat. If the heat stays inside, things get hot fast. Too much heat can slow down chips or break them. Heat sinks pull heat away and send it into the air. This keeps all the parts at a safe temperature. Laptops and LED lights need heat sinks to avoid damage. In cars, heat sinks keep batteries and controls cool. Without heat sinks, devices would break or stop working sooner. Engineers make heat sinks to fit each device. They make sure devices work well, even when used a lot. Good cooling stops sudden shutdowns and keeps people safe.

Tip: Devices with good heat sinks almost never get too hot, even if you use them for a long time.

Enhancing Performance

Heat sinks do more than just stop overheating. They help devices work better and faster. When electronics stay cool, they can run at higher speeds. They can also do more jobs at once. Adding fins, using phase change materials, or changing the shape of a heat sink helps it cool better. This means devices can work harder without getting too hot.

Here is a table that shows how different heat sink designs help devices work better:

Study / Configuration | Key Performance Metrics | Findings Supporting Heat Sink Performance Improvement |

|---|---|---|

Rajesh et al. | PCM and fins | Fins help cooling by moving heat better |

Arshad et al. | Pin fins and PCM | 2 mm pin fins with PCM cool best |

Weng et al. | PCM with heat pipe | Tricosane PCM cut fan energy use by 46% and lowered heater temperature by 12.3°C |

Marri et al. | PCM fill ratios | 99% PCM fill ratio gave the best cooling |

Finned heat sink with heat pipe | Power levels 8-12 W | Charging time improved by ~21%, discharging by ~22% |

Engineers use new designs, like genetic algorithms, to make heat sinks better. These designs help heat sinks cool faster and more efficiently. Devices with these heat sinks work faster and stay cooler.

Device Longevity

Keeping electronics cool helps them last longer. High heat can wear out parts and make them fail early. Heat sinks lower this risk by keeping things cool. Devices that stay cool have fewer problems and last longer. Tests show heat sinks with special materials, like metal foam or graphite, help devices last up to four times longer. Lowering the temperature by just 10°C can double a chip’s life. In power systems, the right heat sink design keeps solar panels and inverters working for years.

Devices with good heat sinks break less often.

Cool electronics keep working well for many years.

Heat sinks stop sudden failures and save money on repairs.

Note: Even a small drop in temperature can help a device last much longer.

Heat sinks keep electronics from getting too hot. New ideas and materials, like graphene and 3D printing, help make better heat sinks. Many things, like cars and computers, need good cooling to work well. Most people do not notice heat sinks, but they help devices last longer. Heat sink technology will keep getting better in the future.

Trend | What to Expect |

|---|---|

Market Growth | Heat sink market could reach $22.92B by 2033 |

New Materials | Graphene and new alloys help cooling work better |

Miniaturization | Smaller and smarter heat sinks for tiny gadgets |

Sustainability | Making heat sinks in eco-friendly ways matters more |

FAQ

What does a heat sink do in electronics?

A heat sink pulls heat away from electronic parts. It helps keep chips, batteries, and lights cool. This cooling stops devices from getting too hot and breaking.

Why do engineers choose aluminum for heat sinks?

Engineers pick aluminum because it is light, cheap, and easy to shape. Aluminum also resists rust and moves heat well. Many laptops and LED lights use aluminum heat sinks.

Can a device work without a heat sink?

Some low-power devices work without a heat sink. High-power devices, like gaming computers or LED lights, need heat sinks. Without one, these devices can overheat and fail.

How do active and passive heat sinks differ?

Active heat sinks use fans or blowers to move air. Passive heat sinks use only their shape and material. Active types cool faster but make noise. Passive types stay silent.

What is a skived heat sink?

A skived heat sink has thin fins cut from one piece of metal. This design gives more surface area for cooling. Skived heat sinks fit well in small spaces.

Do heat sinks need maintenance?

Most passive heat sinks need little care. Active heat sinks with fans need cleaning. Dust can block airflow and lower cooling. Keeping heat sinks clean helps devices last longer.

How do heat sinks help LED lights last longer?

Heat sinks pull heat away from LED chips. This keeps the chips cool and bright. Cool LEDs work better and last many years.

Tip: Clean dust from heat sinks often. This helps them cool better and keeps devices safe.

See Also

A Comprehensive Look At Thyristor Roles In Electronics

Comparing Key Features Of Common Inverter Semiconductor Chips

How Force Sensitive Resistors Drive Innovation In Technology

An Overview Of Optoelectronic Devices And Industrial Applications

Impact Of Passivation Layers On IGBT Durability And Performance