A Simple Guide to Electrostatic Discharge and Its Principles

Electrostatic discharge, or ESD, happens when a sudden transfer of electric charge occurs between two objects with different electrical potentials. You might have experienced this when touching a metal doorknob after walking on a carpet. While it seems harmless, ESD can cause significant problems, especially for electronic devices.

For instance, a consumer electronics company once faced high return rates for smartphones damaged by static electricity during shipping. By using ESD bags, they reduced failures and improved customer satisfaction. Similarly, aerospace companies protect avionics systems from static charges to ensure aircraft safety. These examples highlight how ESD impacts industries and why understanding it is crucial for protecting sensitive equipment.

Key Takeaways

Static electricity (ESD) can harm electronics, even with little charge. Use special tools to keep them safe.

Staying grounded helps stop ESD. Always ground yourself and your workspace to get rid of static safely.

Store and move delicate parts in antistatic bags. This easy step stops expensive damage during transport.

Keep your workspace humidity above 60%. This lowers static buildup and reduces ESD problems.

Handle electronics carefully by following rules. Avoid synthetic fabrics and hold devices by edges to stay safe from ESD.

How Electrostatic Discharge (ESD) Occurs

The Role of Static Electricity

Static electricity plays a key role in the occurrence of ESD. It forms when two materials interact and exchange electrons, creating an imbalance of charges. For example, walking on a rug or rubbing a balloon against a sweater can generate static electricity. These activities cause one object to gain electrons and the other to lose them, resulting in an electrostatic charge. When the charged object comes into contact with another surface, the stored energy releases suddenly, leading to electrostatic discharge.

You may notice static electricity in everyday life. Rubbing clothes in a dryer often creates a charge, causing shocks when you touch someone. Similarly, combing your hair can make it stand on end due to the buildup of static electricity. These simple examples highlight how common static electricity is in your surroundings.

Tribocharging and Charge Buildup

Tribocharging occurs when two materials come into contact and then separate, transferring electrons between them. This process leads to charge buildup, which can create an electric field. Everyday actions like removing plastic packaging or sliding out of a car seat can cause tribocharging. In industrial settings, tribocharging becomes more significant. For instance, helicopter blades can generate voltages as high as 200 kV due to this phenomenon.

Even vehicle tires are designed to dissipate tribocharges to prevent shocks. In space, tribocharging affects communication systems on spacecraft. These examples show how tribocharging contributes to electrostatic charge buildup in various environments.

The Discharge Process and Common Scenarios

The discharge process begins when the potential difference between two objects becomes large enough to overcome the insulating barrier between them. This results in a sudden flow of electrons, which you experience as a shock. Activities like blending materials or moving on conveyor belts can generate static electricity, leading to ESD.

In daily life, you might encounter ESD when touching a metal object after walking on a carpet. In workplaces, static discharge can pose risks, especially in environments with flammable substances. On electronic devices, ESD can damage sensitive components, making it essential to handle them carefully. Understanding these scenarios helps you recognize and mitigate the risks of electrostatic discharge.

The Dangers of Electrostatic Discharge

Risks to Electronic Devices

Electrostatic discharge (ESD) poses a significant threat to electronic devices. Even a small discharge, as low as 3 volts, can damage sensitive components. High-speed devices and those using MOS technology, such as specialized resistors and capacitors, are particularly vulnerable. You might think robust components like bipolar transistors are safe, but they can also fail due to ESD.

Industries like electronics manufacturing face ongoing challenges from ESD. Sensitive components can suffer latent defects, passing initial inspections but failing later. This leads to costly product returns and unresolved customer complaints. Companies often experience production delays and increased quality control expenses due to ESD-related failures. For example, a damaged component may halt production, delaying deliveries and causing financial penalties.

Economic Impact | Description |

|---|---|

Component Failures and Rework | ESD-induced failures lead to warranty claims and customer dissatisfaction, requiring costly rework. |

Production Delays | Failures cause production halts, resulting in delayed deliveries and potential financial penalties. |

Quality Control Expenses | Additional measures for ESD compliance increase overall manufacturing costs. |

Reputation and Brand Damage | ESD failures can damage a company's reputation, leading to loss of customer trust and market share. |

By understanding the dangers of ESD, you can take steps to protect your devices and avoid these costly consequences.

Safety Concerns for Humans

The dangers of electrostatic discharge extend beyond electronics. In healthcare settings, ESD can disrupt medical instruments and data processing equipment. This creates risks for patient safety, as unknown electric failures may occur. For example, malfunctioning equipment in an operating room could lead to life-threatening situations.

Static electricity can also increase airborne microbe contamination in hospitals, contributing to infections. In laboratories or areas with flammable gases, ESD can ignite materials, causing fires or explosions. Even minor electrostatic shocks can harm you. These shocks may cause painful sensations or involuntary movements, leading to accidents.

Tip: To reduce the impact of ESD in sensitive environments, ensure proper grounding and use antistatic tools. These measures can protect both people and equipment from harm.

By recognizing the dangers of ESD, you can take precautions to ensure safety in your surroundings.

Types of ESD Damage

Electrostatic discharge (ESD) can cause different types of damage to electronic components. These damages vary in severity and how they affect the performance of devices. Understanding these types of damage helps you take the right precautions to protect sensitive equipment.

Catastrophic Failures

Catastrophic failures occur when ESD causes immediate and permanent damage to a component. These failures are easy to detect during testing because the device stops functioning entirely or partially. For example, ESD can lead to metal melt, junction breakdown, or oxide failure, all of which render the device unusable.

Imagine a microchip exposed to a sudden electrostatic charge. The intense energy can destroy its internal structures, making it impossible to repair. This type of failure often results in production delays and increased costs for manufacturers. By using proper ESD protection measures, you can prevent these costly outcomes.

Latent Failures

Latent failures are more challenging to identify. Unlike catastrophic failures, these do not cause immediate damage. Instead, ESD weakens the component, allowing it to function temporarily. Over time, the device may experience reduced performance or fail prematurely.

For instance, a smartphone exposed to ESD during assembly might pass initial inspections. However, after months of use, it could develop issues like slower processing speeds or sudden shutdowns. These failures are costly because they often occur after the product has been sold, leading to warranty claims and customer dissatisfaction. To avoid latent failures, you should handle electronic devices carefully and use antistatic tools during assembly.

Long-Term Degradation

ESD can also cause long-term degradation in electronic components. Even a small electrostatic charge can create latent defects that compromise the reliability of a device over time. For example, ESD may damage the delicate structures of a printed circuit board (PCB), leading to electrical shorts or reduced functionality.

This type of damage can also corrupt data in memory devices or disrupt microprocessors, causing system crashes. Over time, these issues reduce the lifespan of the device and increase repair costs. By implementing comprehensive ESD protection strategies, you can ensure the long-term reliability of your electronics.

Note: Always store sensitive devices in antistatic bags and maintain proper grounding to minimize the risk of electrostatic damage.

ESD Protection and Prevention

Grounding Techniques

Grounding is one of the most effective ways to prevent ESD. By connecting objects to a common ground, you can safely dissipate any accumulated electrostatic charge. For example, equipping your workstation with grounding cords and straps ensures that static electricity does not build up on surfaces or equipment. This method is essential in industrial settings where sensitive electronics are handled.

You should also implement a comprehensive grounding program. Regularly inspect and test grounding connections to ensure they function correctly. Train employees on proper grounding techniques to maintain electrostatic-safe areas. These steps help minimize risks and ensure consistent ESD protection measures across your workspace.

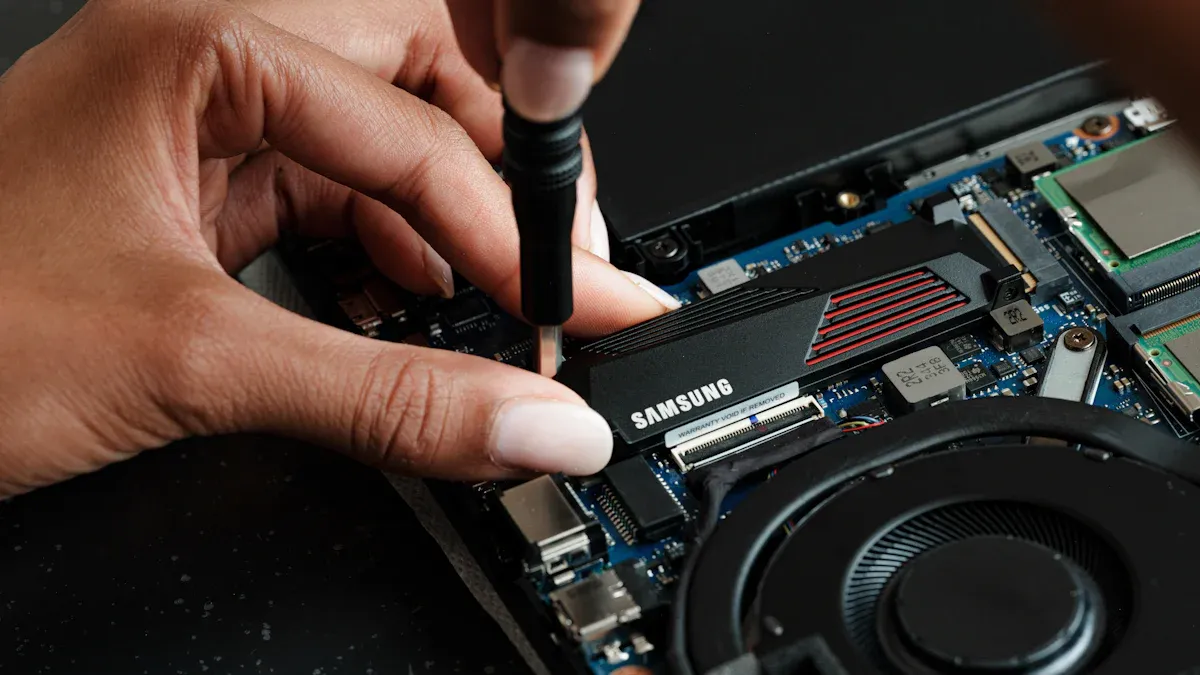

Antistatic Tools and Their Usage

Antistatic tools play a crucial role in protecting against damage caused by ESD. For instance, antistatic bags shield sensitive components from electrostatic charge during storage or transport. Wrist straps ground individuals working on electronic circuits, preventing static buildup.

Other tools include antistatic agents, which you can apply to surfaces to neutralize excess charge, and safety boots designed to dissipate static electricity in industrial environments. Using these tools at your workstation ensures that you handle electronics safely and reduce the risk of ESD-related failures.

Environmental Controls for Static Reduction

Controlling your environment is another key aspect of ESD protection. Maintaining humidity levels above 60% with humidifiers reduces static electricity buildup. You can also use ionizing bars to neutralize electrostatic charge by releasing positive and negative ions into the air.

Additional measures include applying antistatic agents to surfaces, using anti-static mats on carpets, and relocating equipment to minimize static generation. In industrial settings, wearing ESD-safe clothing further reduces risks. By implementing these environmental controls, you create a safer and more efficient workspace for handling electronics.

Tip: Regularly monitor your environment and adjust humidity or static-reducing measures as needed to maintain optimal conditions for ESD protection.

Best Practices for Handling Electronics

Handling electronics safely requires attention to detail and proper techniques to prevent damage caused by esd. By following best practices, you can ensure the longevity and reliability of your devices. Here are some essential tips to keep in mind:

Always Ground Yourself

Before touching any electronic component, ground yourself using an antistatic wrist strap or by touching a grounded metal object. This step prevents esd from damaging sensitive parts.Use ESD-Safe Workstations

Set up a workstation equipped with esd protection tools like antistatic mats and grounding cords. These tools help dissipate static electricity and create a safe environment for handling electronics.Store Components Properly

Always store electronic components in antistatic bags or containers. These materials shield devices from esd during storage and transportation.Avoid Synthetic Materials

Keep synthetic fabrics, such as polyester, away from your workspace. These materials generate static electricity, increasing the risk of esd.Handle Devices by Their Edges

When working with circuit boards or other components, hold them by their edges. Avoid touching connectors or pins, as this minimizes the chance of esd damage.

Tip: Regularly inspect your esd protection tools for wear and tear. Replace damaged items immediately to maintain effective protection.

By implementing these practices, you can significantly reduce the risk of esd. Proper esd protection not only safeguards your devices but also saves you time and money in the long run.

Understanding electrostatic discharge is essential for protecting sensitive electronics and ensuring safety in various environments. ESD can cause catastrophic failures, latent defects, and long-term degradation in devices. These issues often lead to costly repairs, production delays, and customer dissatisfaction.

"ESD control, other than a dramatic increase in sales, is the single most profitable opportunity for industry under today’s economic conditions."

You can implement practical ESD protection measures in daily life. For example, using ESD bags during shipping reduces failures in consumer electronics and safeguards critical medical equipment. Grounding techniques, antistatic tools, and environmental controls also help minimize risks. By adopting these practices, you can prevent damage and improve the reliability of your devices.

FAQ

What is electrostatic discharge, and why is it important?

Electrostatic discharge is the sudden flow of electricity between two charged objects. It matters because it can damage sensitive electronics, disrupt operations, and even cause safety hazards in certain environments. Understanding it helps you protect devices and ensure safety.

How can you tell if ESD has damaged a device?

ESD damage may cause a device to stop working immediately or show issues later, like reduced performance or unexpected failures. Testing equipment can detect some damage, but latent defects might only appear after extended use.

What tools help prevent ESD?

Antistatic tools like wrist straps, mats, and bags protect electronics from ESD. These tools safely dissipate static electricity, reducing the risk of damage. Using them while handling sensitive devices ensures better protection.

Can ESD harm humans?

Yes, ESD can harm humans in specific situations. For example, it can ignite flammable gases or materials, causing fires or explosions. In healthcare, ESD may disrupt medical equipment, creating risks for patients.

How does humidity affect ESD?

Higher humidity reduces static electricity buildup by allowing charges to dissipate more easily. Maintaining humidity levels above 60% in your workspace can help minimize ESD risks.

See Also

Essential Steps You Should Follow for Supercapacitor Testing

Easy Methods for Testing a Zener Diode Effectively

Exploring Various Capacitor Types and Their Unique Characteristics