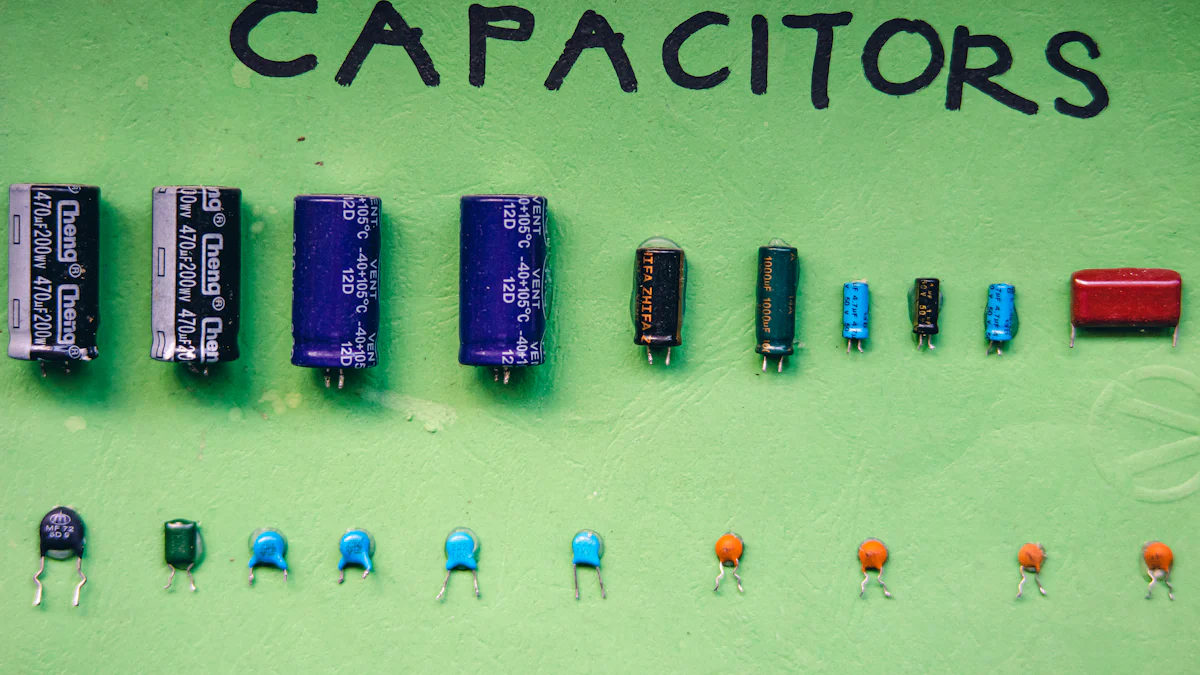

A Guide to Different Types of Capacitors and Their Features

A capacitor and its types are essential components in electronic circuits. A capacitor stores and releases electrical energy, making it vital for various applications. Capacitors play key roles, such as stabilizing power supplies, filtering signals, and storing energy for quick bursts. For example, they smooth out voltage fluctuations in power supply circuits or filter noise in high-frequency applications.

There are several types of capacitors and its types, including ceramic, electrolytic, film, tantalum, and supercapacitors. Each type has unique features suited for specific tasks. Understanding capacitor and its types helps you choose the right one for your project, ensuring optimal performance and reliability.

Key Takeaways

Capacitors hold and release electrical energy, helping in electronic circuits.

Ceramic capacitors are small and work well with high frequencies. They are great for modern gadgets.

Electrolytic capacitors store a lot of energy and help filter power. They must be connected the right way.

Film capacitors are not polarized and stay stable. They are good for audio and high-voltage uses.

Tantalum capacitors are small and dependable, perfect for portable devices. They need correct connection in DC circuits.

Supercapacitors store lots of energy and release it fast. They are useful for backup power systems.

When choosing a capacitor, check capacitance, voltage, and how you will use it.

Do not go over voltage limits and check polarity to avoid problems.

Ceramic Capacitors

Overview of Ceramic Capacitors

Ceramic capacitors are one of the most widely used types of capacitors in electronic circuits. They are made from ceramic materials, which act as the dielectric, and are known for their compact size and versatility. These capacitors come in different classes, each designed for specific applications. Class 1 ceramic capacitors use paraelectric materials like titanium dioxide, modified with additives such as zinc or zirconium, to achieve high stability. Class 2 capacitors, made from barium titanate, offer higher capacitance but are more temperature-sensitive. Class 3 capacitors provide excellent volumetric efficiency but lack precision and stability.

Ceramic capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (μF), and can handle voltages from 2kV to 100kV. Their small size and high reliability make them ideal for modern electronic devices.

Characteristics of Ceramic Capacitors

High-frequency performance

Ceramic capacitors excel in high-frequency applications. Their low equivalent series resistance (ESR) and inductance allow them to perform efficiently in circuits that require rapid charge and discharge cycles. This makes them suitable for high-speed signal processing and radio frequency (RF) circuits.

Stability and temperature tolerance

These capacitors offer excellent stability under varying voltage and temperature conditions. Class 1 ceramic capacitors, in particular, maintain consistent performance, making them ideal for applications requiring precise temperature compensation. Additionally, multilayer ceramic capacitors (MLCCs) provide high packaging density, supporting compact circuit designs.

Applications of Ceramic Capacitors

Decoupling and filtering

Ceramic capacitors play a crucial role in decoupling and filtering applications. They reduce noise in power supply lines and stabilize voltage levels, ensuring smooth operation of electronic circuits. For example, they are commonly used in audio systems to block unwanted frequencies and improve sound quality.

High-frequency circuits

These capacitors are essential in high-frequency circuits, such as RF amplifiers and oscillators. Their ability to handle high voltages and rapid signal changes makes them indispensable in timing circuits and oscillation applications. With capacitance values typically below thousands of picofarads, they are perfect for precise, high-speed operations.

Tip: When selecting a ceramic capacitor, consider the capacitance, voltage rating, and temperature stability required for your application. This ensures optimal performance and reliability.

Electrolytic Capacitors

Overview of Electrolytic Capacitors

Electrolytic capacitors are a popular choice when you need high capacitance in a compact package. These capacitors use an electrolyte as one of their plates, which allows them to achieve much higher capacitance values compared to other types of capacitors. They are polarized, meaning they have a positive and negative terminal, and must be connected correctly in a circuit to avoid damage. You’ll often find them in power supply systems, where they help smooth out voltage fluctuations and store energy for later use.

Electrolytic capacitors come in various types, including aluminum, tantalum, and niobium-based designs. Each type offers unique advantages, such as higher voltage ratings or better reliability. For example, aluminum electrolytic capacitors can handle voltages up to 600V, making them suitable for high-power applications. Their affordability and availability make them a go-to option for many engineers.

Characteristics of Electrolytic Capacitors

High capacitance values

One of the standout features of electrolytic capacitors is their ability to provide high capacitance values. This makes them ideal for applications requiring significant energy storage or bulk capacitance. For instance, aluminum electrolytic capacitors can achieve capacitance values in the range of microfarads (μF) to farads (F). This capability allows them to stabilize power supplies and store energy efficiently.

Polarized nature

Unlike ceramic capacitors, electrolytic capacitors are polarized. This means you must connect them with the correct polarity in your circuit. The positive terminal connects to the higher voltage side, while the negative terminal connects to the lower voltage side. Reversing the polarity can lead to capacitor failure, such as short circuits or even explosions. This characteristic makes them unsuitable for AC applications but perfect for DC circuits.

Aspect | Ceramic Capacitors | Electrolytic Capacitors |

|---|---|---|

Lower capacitance values | Higher capacitance values | |

Frequency Response | Better high-frequency performance | May not perform as well at high frequencies |

Applications | High-frequency and decoupling applications | Power supply filtering and bulk storage |

Polarization | Non-polarized | Polarized |

Voltage Rating | Generally lower voltage ratings | Higher voltage ratings |

Applications of Electrolytic Capacitors

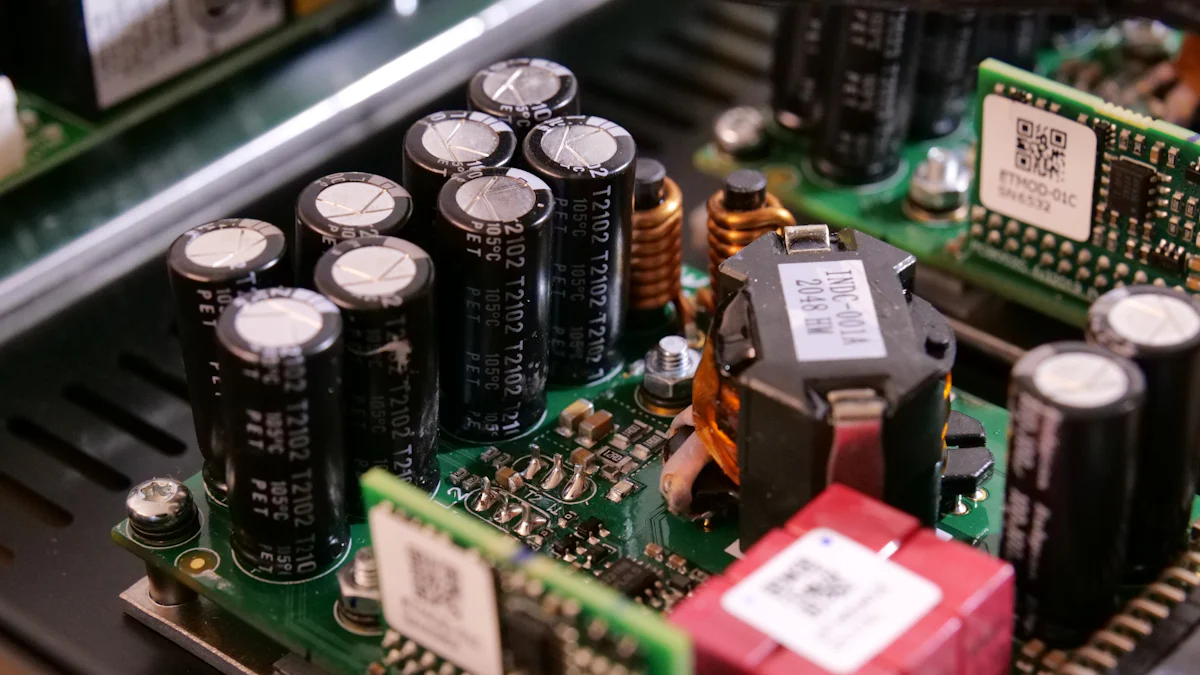

Power supply filtering

Electrolytic capacitors are essential in power supply systems. They filter out voltage ripples and stabilize the output, ensuring smooth operation of electronic devices. For example, in switched-mode power supplies, these capacitors work in power factor correction stages and help maintain a steady DC voltage. They also prevent voltage regulator dropout during brief AC power interruptions by compensating for load current changes.

Energy storage

When it comes to energy storage, electrolytic capacitors excel. Their high capacitance values allow them to store large amounts of energy, which can be released quickly when needed. This makes them ideal for applications like backup power systems and energy harvesting. For instance, aluminum electrolytic capacitors with roughened foil can handle voltages up to 600V, making them suitable for industrial energy storage solutions.

Capacitor Type | |

|---|---|

Aluminum (roughened foil) | 600 |

Solid Manganese dioxide | 40 |

Solid conductive polymer | 250 |

Tantalum (roughened foil) | 630 |

Tantalum (sintered) | 150 |

Note: To extend the lifespan of an electrolytic capacitor, avoid exceeding its voltage rating or subjecting it to excessive ripple currents. Proper circuit design can mitigate common failure modes, such as capacitance drop or leakage current increase.

Film Capacitors

Overview of Film Capacitors

Film capacitors are a versatile and reliable option among the various types of capacitors. They use a thin plastic film as the dielectric, which is often metallized to enhance performance. These capacitors are non-polarized, making them suitable for both AC and DC applications. You’ll find them in a wide range of capacitance values and voltage ratings, making them adaptable to many circuit designs.

Manufacturers use different materials to construct film capacitors, each offering unique benefits. For example, polypropylene (PP) accounts for 50% of the market due to its excellent electrical properties, while polyester (PET) makes up 40% because of its affordability and compact size. Other materials, such as PPS and paper, make up the remaining 10%. This variety ensures you can select a film capacitor tailored to your specific needs.

Material | Market Share |

|---|---|

Polypropylene (PP) | 50% |

Polyester (PET) | 40% |

Other materials (PPS, paper) | 10% |

Characteristics of Film Capacitors

Excellent stability

Film capacitors stand out for their exceptional stability. They maintain consistent performance over time and under varying temperature conditions. Their low equivalent series resistance (ESR) and equivalent series inductance (ESL) contribute to this stability, ensuring reliable operation in demanding environments. Unlike other capacitor types, film capacitors are not polarized, allowing you to use them in AC circuits without worrying about DC bias.

Low loss factor

Another key advantage of film capacitors is their low loss factor. This means they exhibit minimal energy loss during operation, making them highly efficient. Their low dielectric loss is particularly beneficial in high-frequency applications, where efficiency is critical. This feature also makes them ideal for power factor correction and high-quality audio circuits, where maintaining signal integrity is essential.

Applications of Film Capacitors

Audio circuits

Film capacitors are a favorite in audio circuits due to their low distortion and stable performance across a wide frequency range. High-quality audio systems often use polypropylene film capacitors for their excellent sound fidelity and minimal dielectric loss. You’ll find them in audiophile-grade equipment and audio crossovers in loudspeakers, where they ensure precise frequency separation and superior sound quality.

High-voltage applications

In high-voltage applications, film capacitors excel because of their ability to handle significant electrical stress. They are commonly used in industrial equipment, power factor correction systems, and high-voltage power supplies. However, you should be cautious when selecting a film capacitor for such applications. Using a DC-rated film capacitor in an AC circuit can lead to short-circuiting or ignition. Additionally, factors like high humidity and voltage can exacerbate failure mechanisms, such as dielectric breakdown or increased leakage current. Proper design and material selection can help mitigate these risks.

Tip: When choosing a film capacitor, consider the dielectric material, capacitance, and voltage rating to ensure it meets your application’s requirements. This careful selection will enhance the reliability and performance of your circuit.

Tantalum Capacitors

Overview of Tantalum Capacitors

Tantalum capacitors are a popular choice when you need a compact and reliable solution for electronic circuits. These capacitors use tantalum metal as the primary material for their electrodes, which allows them to achieve high capacitance values in a small package. Unlike many other types of capacitors, tantalum capacitors are polarized, meaning they must be connected with the correct polarity in DC circuits. Their unique construction makes them highly stable and consistent, even under varying voltage conditions.

However, tantalum capacitors come with some environmental considerations. Tantalum is a heavy metal, and its extraction can have ethical and ecological implications. Many tantalum ore mines are located in conflict zones, raising concerns about sustainability and responsible sourcing.

Note: Tantalum capacitors are not ideal for applications requiring non-polarized components or exposure to AC signals. Always check your circuit requirements before selecting this capacitor type.

Characteristics of Tantalum Capacitors

Compact size

Tantalum capacitors are known for their small size and high capacitance per unit volume. This makes them ideal for applications where space is limited. For example, they are often used in smartphones, tablets, and other portable devices. Their compact design allows you to create sleek, lightweight products without sacrificing performance.

High reliability

These capacitors offer excellent reliability, especially in low-voltage applications. They maintain consistent capacitance over time and do not age like ceramic capacitors. However, they require external failsafe devices to prevent catastrophic failure in case of overvoltage or reverse polarity. This makes them a dependable choice for circuits where stability and longevity are critical.

Feature | Tantalum Capacitors | Ceramic Capacitors |

|---|---|---|

Size | Generally larger than ceramic capacitors | Typically smaller in size |

Reliability | Require external failsafe devices; do not age | Age over time; known to have a wear-out mechanism |

Polarization | Polarized, can only connect to DC with correct polarity | Non-polarized, can connect to AC sources safely |

Capacitance Stability | Consistent stability under voltage changes | Capacitance can change significantly with voltage |

Applications of Tantalum Capacitors

Portable electronics

Tantalum capacitors are widely used in portable electronics due to their compact size and high capacitance. You’ll find them in devices like smartphones, tablets, laptops, and medical equipment. They are also common in audio amplifiers and automotive circuits, where their stability and reliability enhance performance. Their ability to store significant energy in a small package makes them indispensable in modern electronic designs.

Common applications include:

Cell phones

PCs and laptops

Medical devices

Automotive circuitry

Space-constrained designs

When designing circuits for tight spaces, tantalum capacitors are an excellent choice. Their small footprint allows you to maximize functionality without increasing the size of your product. This makes them ideal for wearable devices, compact power supplies, and other space-constrained applications. Their consistent performance under voltage fluctuations ensures your design remains reliable, even in demanding environments.

Tip: Always verify the voltage and polarity requirements of your circuit before using tantalum capacitors. This will help you avoid potential failures and ensure optimal performance.

Supercapacitors

Overview of Supercapacitors

Supercapacitors, also known as ultracapacitors, are a unique type of capacitor designed for applications requiring extremely high capacitance and rapid energy delivery. Unlike traditional capacitors, which rely on electrostatic fields for energy storage, supercapacitors use electrochemical mechanisms. This allows them to store significantly more energy and deliver it in quick bursts. You’ll often find them in systems where high power density and long cycle life are essential.

Supercapacitors bridge the gap between traditional capacitors and batteries. They can endure up to one million charge-discharge cycles without significant degradation, making them highly durable. Their capacitance values range from 0.1 farads (F) to an impressive 12,000 F, far exceeding the typical range of traditional capacitors, which max out at several thousand microfarads (μF).

Traditional Capacitors | Supercapacitors | |

|---|---|---|

Energy Storage Capacity | Lower | Higher |

Charge/Discharge Cycle Life | Shorter | Longer (up to 1 million cycles) |

Energy Delivery Speed | Slower | Quick bursts of energy |

Mechanism of Energy Storage | Electrostatic fields | Electrochemical mechanisms |

Applications | General use | High-power applications |

Characteristics of Supercapacitors

Extremely high capacitance

Supercapacitors stand out due to their massive capacitance values. While traditional capacitors typically range from a few picofarads (pF) to several thousand microfarads, supercapacitors start at 0.1 F and go up to 12,000 F. This high capacitance enables them to store large amounts of energy, making them ideal for applications requiring temporary energy storage or backup power.

Rapid charge and discharge

Another key feature of supercapacitors is their ability to charge and discharge quickly. They utilize a double-layer charge storage mechanism, which allows for rapid energy transfer. This makes them perfect for applications that demand immediate power delivery, such as regenerative braking systems in electric vehicles or energy harvesting devices. Their quick response time ensures efficient performance in high-power scenarios.

Tip: When selecting a supercapacitor, consider its capacitance, voltage rating, and cycle life to ensure it meets your application’s requirements.

Applications of Supercapacitors

Energy harvesting

Supercapacitors play a vital role in energy harvesting systems. They capture and store energy from renewable sources like mechanical movement, light, and electromagnetic fields. For example, they can store energy harvested from RF fields to power an application-specific integrated circuit (ASIC) for over 10 hours. Their ability to store and release energy quickly makes them indispensable in systems that rely on intermittent energy sources.

Common energy harvesting sources include:

Solar panels

Piezoelectric devices

Electromagnetic fields

Backup power systems

In backup power systems, supercapacitors provide a reliable solution for short-term energy storage. They deliver quick bursts of energy during power outages or voltage drops, ensuring uninterrupted operation of critical devices. You’ll often find them in uninterruptible power supplies (UPS), emergency lighting systems, and industrial equipment. Their long cycle life and rapid charge-discharge capabilities make them a cost-effective alternative to batteries in many scenarios.

Note: Supercapacitors are not a replacement for batteries in long-term energy storage applications. However, they complement batteries by handling high-power demands and extending battery life.

Other Capacitor Types

Mica Capacitors

Characteristics

Mica capacitors stand out for their exceptional stability and reliability. These capacitors use mica, a natural mineral, as the dielectric material, which ensures consistent performance even under challenging conditions. They maintain their capacitance value across high temperatures, voltages, and frequencies. Their simple structure, free of electrolytes, contributes to a long service life. Additionally, mica capacitors exhibit low dielectric loss, making them ideal for high-frequency applications. They also resist high temperatures without degradation and can handle significant voltage levels.

Characteristic | Description |

|---|---|

High stability | Maintains capacitance under high temperature, voltage, and frequency. |

High reliability | Simple structure without electrolytes ensures long service life. |

Low loss performance | Exhibits low dielectric loss, ensuring signal quality in high-frequency applications. |

High-temperature resistance | Operates in high-temperature environments without degradation. |

Voltage resistance | Withstands high voltages, suitable for demanding applications. |

Large capacity | Offers capacitance ranging from nanofarads to hundreds of microfarads. |

Applications

You’ll often find mica capacitors in high-frequency circuits due to their precision and stability. They are used in filtering circuits to eliminate high-frequency noise and stabilize signals. In coupling circuits, they transmit signals between different parts of a system. Additionally, mica capacitors play a key role in resonant circuits, where they help adjust and control frequency.

Common applications include:

Filtering circuits

Coupling circuits

Resonant circuits

Paper Capacitors

Characteristics

Paper capacitors were among the earliest types of capacitors used in electronics. They use paper as the dielectric material, often impregnated with oil or wax to enhance performance. These capacitors are known for their high voltage tolerance, making them suitable for heavy-duty applications. They also offer long-term reliability, which has made them a popular choice in power electronics. While modern alternatives have largely replaced them, paper capacitors remain relevant in specific high-voltage applications.

Applications

Historically, paper capacitors were widely used in telecommunications as decoupling capacitors. Their ability to handle high voltages made them essential in power transmission and distribution systems. They also found applications in power electronics, where they managed high voltage and current scenarios. Although newer types of capacitors dominate the market, paper capacitors still serve niche roles in heavy-duty and high-voltage applications.

Common applications include:

Power transmission systems

High-voltage power electronics

Decoupling in telecommunications

Glass Capacitors

Characteristics

Glass capacitors are known for their durability and exceptional performance. They use glass as the dielectric material, which provides high tolerance to environmental factors like moisture and radiation. This ensures long-term reliability, even in harsh conditions. Glass capacitors exhibit a low dissipation factor, minimizing energy loss. They also maintain exceptional stability, with temperature coefficients as low as 10 PPM/°C. Their capacitance remains consistent over time, with minimal drift and no voltage coefficient. These features make them ideal for high-frequency and high-temperature applications.

Feature | Mica Capacitors | Glass Capacitors |

|---|---|---|

Stability | Extremely high stability | |

Temperature Resistance | -55°C to +125°C, up to 200°C | High resistance to extreme temperatures |

Voltage Strength | High voltage strength | Suitable for high voltages and radiation environments |

Application Suitability | Dominates in filter applications | Suitable for harsh environments |

Applications

Glass capacitors excel in high-reliability circuits, especially in military, aerospace, and medical equipment. Their ability to withstand extreme temperatures and radiation makes them suitable for harsh environments. You’ll find them in aerospace and space applications, where they tolerate high radiation levels. They are also used in missile and satellite designs, thanks to their low loss and high "Q" factor at elevated temperatures and frequencies.

Common applications include:

Military and aerospace circuits

Medical equipment

Satellite and missile designs

Tip: When choosing between mica and glass capacitors, consider the environmental conditions and performance requirements of your application. Glass capacitors perform better in extreme environments, while mica capacitors excel in high-frequency filtering.

Understanding the various types of capacitors helps you make informed decisions for your electronic projects. Ceramic capacitors excel in high-frequency circuits, while electrolytic capacitors provide high capacitance for power supply filtering. Film capacitors offer stability and low loss, making them ideal for audio and high-voltage applications. Tantalum capacitors shine in compact designs, and supercapacitors deliver rapid energy bursts for backup systems.

When selecting a capacitor, consider factors like capacitance value, voltage rating, and temperature stability. Check for polarization, especially with electrolytic capacitors, and avoid exceeding voltage ratings to prevent failures. Ignoring specifications like leakage current or dissipation factor can lead to reduced performance or lifespan. By understanding these details, you ensure optimal circuit performance and reliability.

Tip: Always match the capacitor's specifications to your circuit's requirements to avoid common mistakes like overlooking voltage ratings or aging effects.

FAQ

What is the main purpose of a capacitor in a circuit?

A capacitor stores electrical energy and releases it when needed. It stabilizes voltage, filters signals, and provides energy for short bursts in electronic circuits.

How do you choose the right capacitor for your project?

Consider the capacitance value, voltage rating, and application requirements. Check if the capacitor is polarized or non-polarized. Match these specifications to your circuit's needs.

Can you use electrolytic capacitors in AC circuits?

No, electrolytic capacitors are polarized. They work only in DC circuits. Using them in AC circuits can cause damage or failure.

Why are ceramic capacitors popular in high-frequency applications?

Ceramic capacitors have low equivalent series resistance (ESR) and inductance. These features make them efficient for high-speed signal processing and RF circuits.

What makes supercapacitors different from traditional capacitors?

Supercapacitors store much more energy and charge or discharge rapidly. They are ideal for applications requiring high power density and long cycle life.

Are tantalum capacitors suitable for all applications?

No, tantalum capacitors are polarized and unsuitable for AC circuits. They work best in compact designs and low-voltage DC applications.

How do film capacitors benefit audio circuits?

Film capacitors offer low distortion and stable performance. These qualities ensure high sound fidelity in audio systems.

What precautions should you take when using capacitors?

Avoid exceeding the voltage rating. Check for polarity in electrolytic and tantalum capacitors. Ensure proper storage and handling to prevent damage.

See Also

Essential Tips for Choosing the Right Car Relays

Understanding Key Differences Between CR1620 and CR2032 Batteries