What is a Camshaft Position Sensor and How Does It Work

The camshaft position sensor is a vital component of your vehicle's engine. It monitors the camshaft's position and speed, ensuring precise timing for ignition and fuel injection. This precision allows the engine to operate efficiently and deliver optimal engine performance. Modern vehicles rely on this sensor to enhance fuel efficiency, reduce emissions, and meet strict environmental standards. Without it, your engine's performance could suffer, leading to poor fuel economy and increased emissions. By maintaining accurate timing, the camshaft position sensor plays a crucial role in keeping your vehicle running smoothly.

Key Takeaways

The camshaft position sensor is important for the engine to work well. It helps with the right timing for ignition and fuel injection. This improves fuel use and reduces pollution.

Knowing the signs of a bad camshaft position sensor can save money. Watch for engine misfires, bad gas mileage, or trouble starting your car.

Checking and cleaning the camshaft position sensor often can stop problems. Regular engine check-ups can find issues before they get worse.

An OBD-II scanner is a good tool to find sensor problems. It shows error codes that point to sensor troubles.

Replacing a broken camshaft position sensor quickly makes the engine run better. Fix it yourself or get help, but don’t wait to avoid bigger issues.

What is a Camshaft Position Sensor?

Definition and Purpose

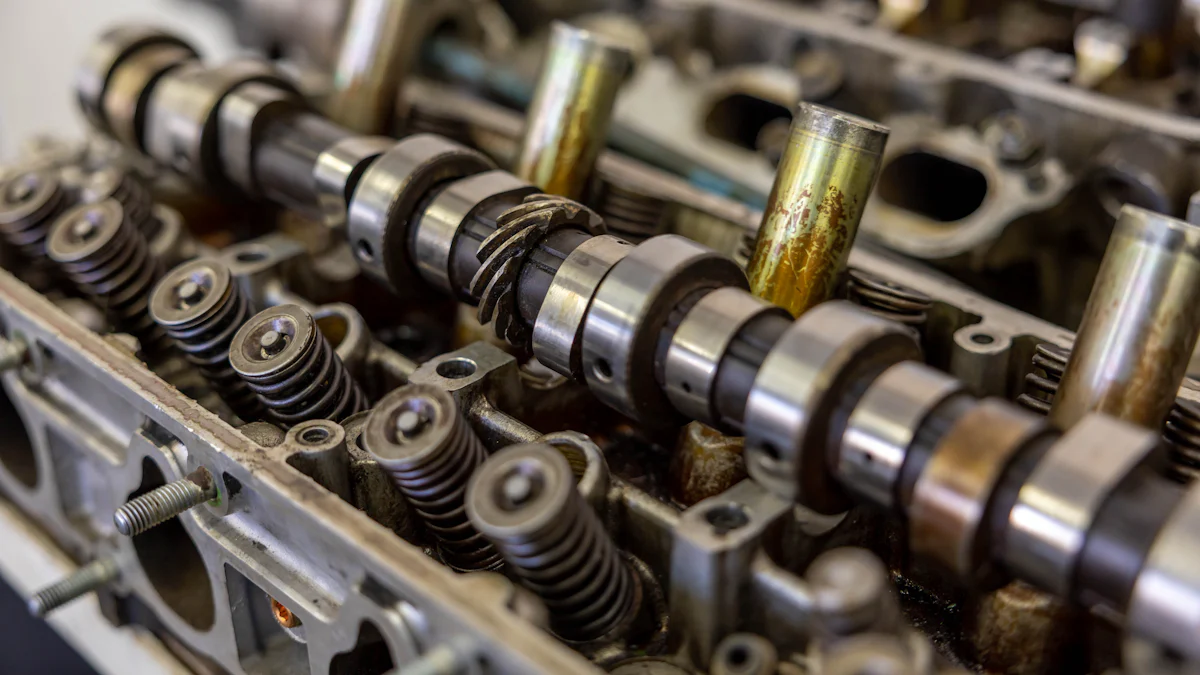

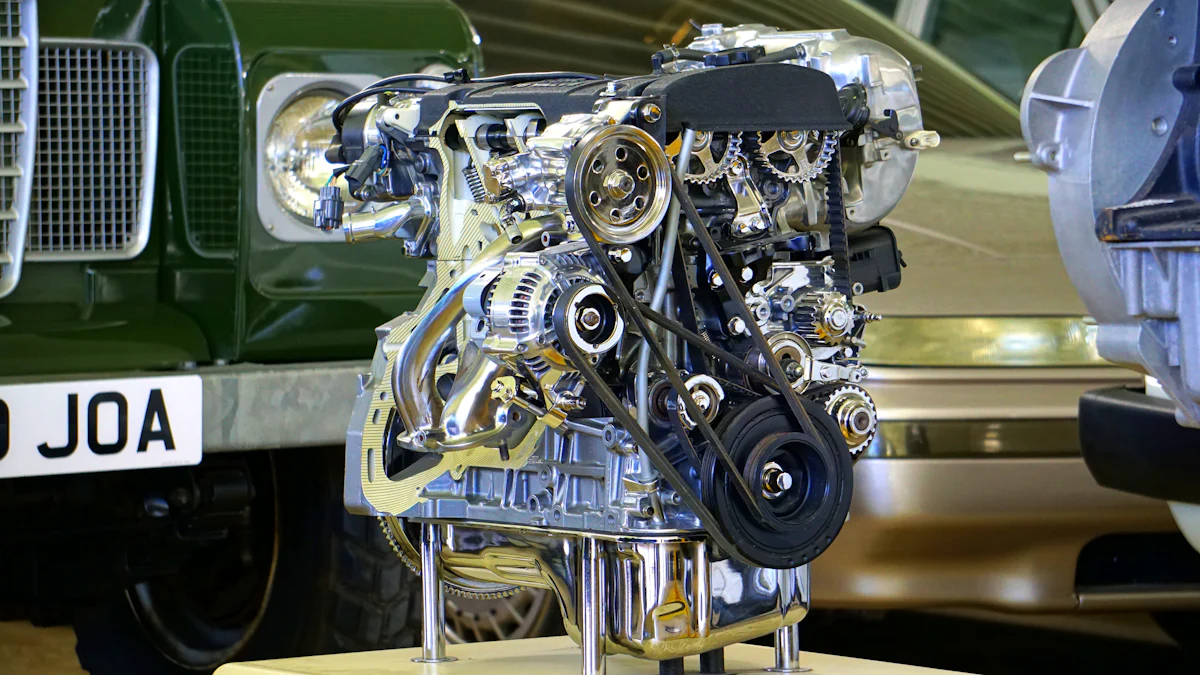

A camshaft position sensor is an electromechanical device that plays a critical role in internal combustion engines. It monitors the position and speed of the camshaft, which controls the opening and closing of the engine's intake and exhaust valves. This sensor works by detecting the camshaft's rotation and sending this data to the engine control unit (ECU). The ECU uses this information to calculate ignition timing and fuel injection, ensuring optimal engine performance.

Camshaft position sensors typically consist of two main components:

A sensor body containing the sensing element.

A reluctor wheel or tone ring mounted on the camshaft.

Different types of camshaft position sensors exist, including Hall-effect sensors, magnetic sensors, and optical sensors. Each type uses a unique mechanism to detect camshaft movement. These sensors work alongside the crankshaft position sensor to synchronize valve operation and maintain precise engine timing.

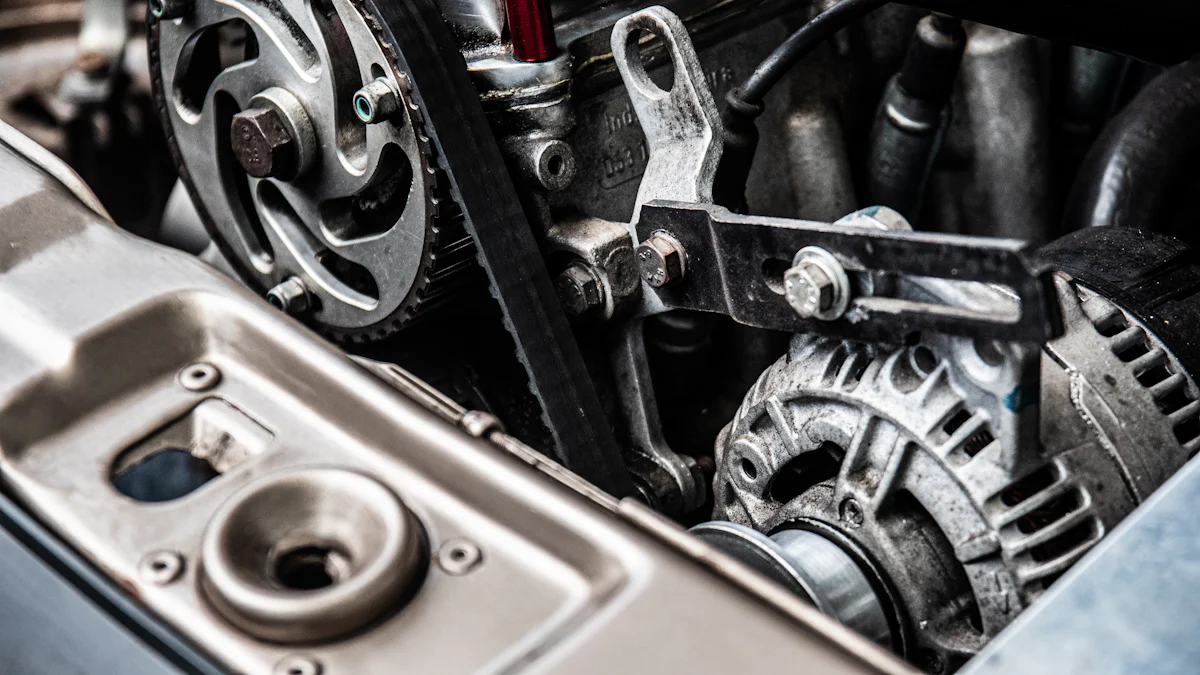

Location in the Engine

You can usually find the camshaft position sensor near the camshaft itself. In most modern engines, it is mounted at the top of the engine, often on the cylinder head or engine block. Inline engines typically have the sensor positioned close to the camshaft sprocket or timing belt/chain.

In V-shaped or boxer engines, the sensor's location may vary due to the engine's geometry. Some engines place the sensor in the engine block, while others position it near the flywheel or transmission bell. Regardless of its exact location, the sensor is always close to the camshaft it monitors.

Importance for Engine Timing and Performance

The camshaft position sensor is essential for precise engine timing. It ensures that the intake and exhaust valves open and close at the right moments during the engine's four-stroke cycle. By providing accurate data about the camshaft's position, the sensor helps the ECU synchronize ignition timing with the pistons' position. This synchronization is crucial for efficient combustion, which directly impacts engine performance.

Without a functioning camshaft position sensor, your engine may experience misfires, reduced power, or poor fuel economy. The sensor's role in maintaining proper timing ensures that your vehicle operates smoothly and delivers optimal engine performance.

How Does a Camshaft Position Sensor Work?

Role in Ignition Timing

The camshaft position sensor plays a key role in ensuring your engine fires at the right time. It gathers data about the camshaft's position and sends it to the engine control unit (ECU). The ECU uses this information to synchronize ignition timing with the pistons' position. This synchronization ensures that the spark plugs ignite the air-fuel mixture at the optimal moment, leading to efficient combustion.

Accurate ignition timing improves fuel economy and enhances power output. Without this sensor, your engine might misfire or lose efficiency. For example, Hall-effect sensors generate a voltage signal by detecting changes in the magnetic field caused by a toothed reluctor wheel. This signal helps the ECU determine the exact timing for ignition events.

Role in Fuel Injection

The camshaft position sensor also regulates fuel injection timing. It provides critical data to the ECU, which determines when and how much fuel to inject into the combustion chamber. Proper timing ensures that the fuel mixes with air at the right moment, optimizing combustion.

This process not only improves engine performance but also reduces harmful emissions. For instance, magnetic sensors detect changes in magnetic flux as the camshaft rotates, helping the ECU time fuel injection precisely. By maintaining this precision, the sensor ensures your vehicle runs smoothly and efficiently.

Interaction with the Engine Control Unit (ECU)

The camshaft position sensor works closely with the ECU to optimize engine performance. It continuously monitors the camshaft's position and sends real-time data to the ECU. This data includes information about ignition timing and fuel injection.

The ECU uses this input to ensure that each cylinder fires at the correct moment. This synchronization leads to efficient combustion, better fuel economy, and reduced emissions. For example, optical sensors use light beams interrupted by a slotted disc to monitor the camshaft's rotation. This data helps the ECU make precise adjustments, ensuring your engine operates at peak efficiency.

Without a functioning camshaft position sensor, the ECU cannot properly control ignition and fuel injection. This can result in poor engine performance and increased fuel consumption.

Signs of a Failing Cam Sensor

Common Symptoms

A failing camshaft position sensor can cause several noticeable issues in your vehicle. Recognizing these symptoms early can help you avoid more significant problems.

Engine misfires or stalling

One of the most common symptoms of a failing camshaft position sensor is engine misfires or stalling. You may notice hesitation during acceleration or a rough idle when the sensor starts to fail. This happens because the sensor cannot provide accurate data to the engine control unit (ECU), disrupting the ignition and fuel injection timing.

Poor fuel economy

A faulty camshaft position sensor can also lead to poor fuel economy. When the sensor fails, the ECU may inject too much or too little fuel into the combustion chamber. This imbalance reduces efficiency and increases fuel consumption, costing you more at the pump.

Difficulty starting the engine

A failing cam sensor can make it hard to start your vehicle. If the sensor cannot send the correct data to the ECU, the engine may struggle to ignite the air-fuel mixture. In severe cases, this issue can result in a no-start condition, leaving you stranded.

Dashboard Warning Lights

The check engine light is one of the most reliable indicators of a faulty camshaft position sensor. When the sensor malfunctions, the ECU detects the issue and triggers this warning light. You might also experience other symptoms, such as poor drivability or a no-start condition, alongside the illuminated check engine light. Always address dashboard warnings promptly to prevent further damage to your vehicle.

Consequences of a Bad or Failing Camshaft Position Sensor

Ignoring a bad or failing camshaft position sensor can lead to serious consequences. Poor drivability, transmission shifting problems, and bad fuel economy are common outcomes. In some cases, your vehicle may not start at all. A faulty camshaft sensor can also cause your car to stall unexpectedly, creating dangerous situations on the road. Additionally, prolonged neglect can result in higher repair costs and further damage to other engine components.

Tip: Addressing signs of a failing cam sensor early can save you from costly repairs and ensure your vehicle remains safe and reliable.

Troubleshooting and Maintenance for a Failing Camshaft Position Sensor

Diagnosing a Faulty Sensor

Using an OBD-II scanner

An OBD-II scanner is one of the most effective tools for diagnosing a failing camshaft position sensor. This device connects to your vehicle's ECU and retrieves trouble codes that indicate sensor-related issues. These codes help you pinpoint the problem, even if it stems from a deeper issue within the engine.

To diagnose the sensor, follow these steps:

Identify the type of camshaft position sensor in your vehicle (magnetic or Hall effect).

Use an oscilloscope to test the sensor's output signal for accuracy.

If you don’t have an oscilloscope, use a digital multimeter to check the sensor’s voltage output and resistance.

Visual inspection for damage or wear

A visual inspection can reveal physical damage or wear on the sensor. Check the wiring and connections for signs of corrosion, fraying, or loose connections. Look for cracks or debris buildup on the sensor itself. These issues can disrupt the sensor’s ability to send accurate data to the ECU, leading to symptoms of a failing cam sensor.

Maintenance Tips to Prevent Failure

Regular engine check-ups

Routine maintenance is essential for preventing a failing camshaft position sensor. Schedule regular engine inspections to catch potential issues early. This proactive approach ensures your vehicle remains reliable and avoids costly repairs.

Keeping the sensor clean and free of debris

Dirt and debris can interfere with the sensor’s performance. Keep the engine clean to prevent contaminants from affecting the sensor. Periodically inspect the sensor and its surroundings, removing any buildup that could lead to failure. Using high-quality fuel and oil also reduces wear on engine components, including the sensor.

When and How to Replace the Sensor

Knowing how to replace cam sensors is crucial when they fail. Frequent check engine light warnings, poor engine performance, or failed diagnostic tests often indicate the need for replacement. Follow these steps to replace the sensor:

Disconnect the battery to ensure safety.

Locate the camshaft position sensor in your engine.

Remove the old sensor carefully.

Install the new sensor in its place.

Reconnect the battery.

Test the installation by starting the engine and checking for proper operation.

Replacing a failing camshaft position sensor promptly prevents further damage to your vehicle and restores optimal performance.

Cost of Replacing a Camshaft Position Sensor

Average Replacement Costs

The cost of replacing a cam sensor varies depending on your vehicle's make and model. On average, you can expect to pay between $95 and $336. Below is a table showing the cost range for some popular vehicles:

Vehicle Model | Cost Range |

|---|---|

Ford F-150 | $95 - $126 |

Toyota Camry | $177 - $237 |

Chevrolet Silverado 1500 | $134 - $177 |

Honda Accord | $248 - $336 |

Honda Civic | $186 - $260 |

Toyota Corolla | $152 - $209 |

Nissan Altima | $122 - $205 |

Honda CR-V | $125 - $152 |

These costs include parts and labor. However, prices may vary based on your location and the type of repair shop you choose.

Factors Affecting the Cost

Several factors influence the cost of replacing a cam sensor. Understanding these can help you estimate expenses more accurately:

Vehicle Make and Model: Luxury or high-performance vehicles often require more expensive parts and specialized labor.

Location: Labor rates differ by region. Urban areas typically have higher rates than rural locations.

Parts Quality: Original Equipment Manufacturer (OEM) parts cost more than aftermarket alternatives but offer better reliability.

DIY vs. Professional Repair: Doing the replacement yourself saves on labor costs but requires tools and mechanical skills.

DIY vs. Professional Replacement

Choosing between DIY and professional replacement depends on your skills and budget. The table below highlights the advantages and disadvantages of each option:

Replacement Method | Advantages | Disadvantages |

|---|---|---|

Saves on labor costs; cost-effective for skilled individuals | Requires tools and mechanical expertise; risk of errors | |

Professional Repair | Ensures proper installation and diagnosis; peace of mind | More expensive; potential for higher costs |

If you have the tools and knowledge, DIY replacement can reduce the cost of replacing a cam sensor. However, professional repair ensures the job is done correctly, minimizing the risk of further engine issues.

The camshaft position sensor plays a vital role in keeping your engine reliable and efficient. It ensures precise timing for ignition and fuel injection, preventing issues like misfires, rough idling, or poor fuel economy. Accurate sensor data allows the ECU to maintain smooth engine operation and drivability.

Timely diagnosis and maintenance are essential to avoid costly repairs. Regular inspections help catch potential problems early, preserving fuel efficiency and reducing emissions. Ignoring symptoms like stalling or difficulty starting can lead to more significant engine damage. Addressing these issues promptly keeps your vehicle running smoothly and saves you money in the long run.

Take action at the first sign of trouble. A well-maintained camshaft position sensor ensures your engine performs at its best.

FAQ

1. How long does a camshaft position sensor last?

A camshaft position sensor typically lasts 100,000 miles or more. However, its lifespan depends on driving conditions and maintenance. Regular engine check-ups and keeping the sensor clean can extend its life.

Tip: Inspect the sensor during routine maintenance to catch potential issues early.

2. Can you drive with a failing camshaft position sensor?

Driving with a failing sensor is risky. It can cause engine misfires, stalling, or poor fuel economy. In severe cases, your car may not start. Address the issue promptly to avoid further damage.

Note: Ignoring the problem can lead to costly repairs.

3. What tools do you need to replace a camshaft position sensor?

You’ll need basic tools like a socket wrench, screwdriver, and possibly an OBD-II scanner. Some vehicles may require specialized tools depending on the sensor’s location.

Reminder: Always disconnect the battery before starting the replacement process.

4. How do you know if the camshaft position sensor is the problem?

Use an OBD-II scanner to check for trouble codes. Common symptoms include engine misfires, stalling, or difficulty starting. A visual inspection can also reveal damage or debris on the sensor.

Tip: Consult a professional if you’re unsure about the diagnosis.

5. Is replacing a camshaft position sensor expensive?

Replacement costs range from $95 to $336, depending on your vehicle. DIY replacement saves labor costs but requires tools and knowledge. Professional repair ensures proper installation.

Replacement Method | Cost |

|---|---|

DIY | $50-$150 |

Professional | $150-$336 |

Advice: Choose the method that fits your skills and budget.

See Also

Exploring Various Capacitor Types And Their Unique Characteristics

Understanding The Roles Of Circuit Board Elements In Electronics

Steps To Evaluate Starters For Cars, Bikes, And Lawnmowers

Essential Tips For Selecting The Right Relays For Your Vehicle

Understanding Voltage Regulator Modules: Key Considerations To Know