Active Transducers Redefining Precision and Performance

You use technology for many parts of daily life, like healthcare and transportation. Active transducers are key devices that change physical signals into electrical ones we can measure. These tools are very important for making systems work accurately. New technology, especially in 2025, has greatly improved these transducers. They now offer better precision and performance, changing industries and improving daily life.

Key Takeaways

Active transducers change physical signals into electrical ones. This improves accuracy in many industries.

IoT helps monitor data instantly. It boosts efficiency and speeds up decisions in automation.

New materials make transducers stronger and more sensitive. They work well even in tough conditions.

Smaller transducers are useful in wearables and medical tools. They improve healthcare and user experience.

AI and machine learning make transducers smarter. They predict problems and process signals better.

Active transducers are important in renewable energy. They help save energy and reduce waste in factories.

Custom transducers are made for specific industries. This improves how they work and meets special needs.

Research, training, and system updates are key. These help industries use new transducer technology fully.

Latest Advancements in Active Transducer Technology

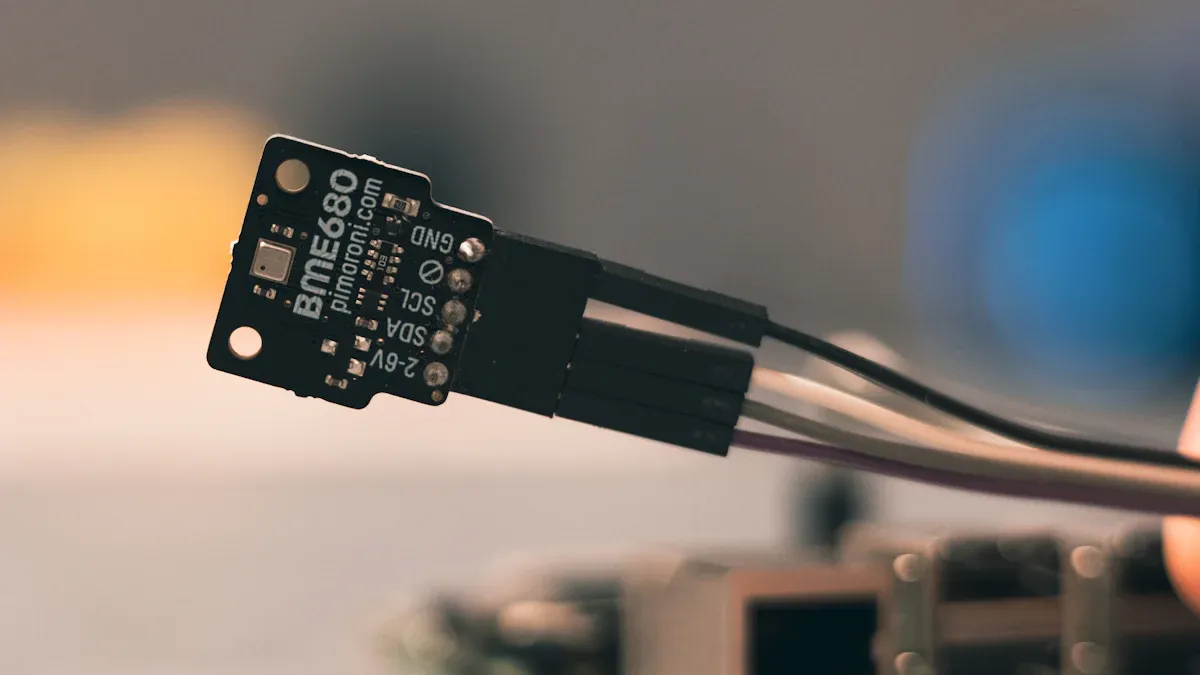

IoT Integration in Active Transducers

Real-time data monitoring and analytics

The Internet of Things (IoT) has changed how active transducers work. These devices now connect to IoT networks for instant data tracking. You can monitor performance, spot problems, and make quick decisions. For example, machines with active transducers adjust themselves using IoT. This boosts efficiency and cuts downtime. Projects like STEPR show how Wi-Fi in fitness gear shares data instantly. This improves user experience and allows more customization.

Enhanced connectivity for industrial automation

IoT-enabled transducers are transforming factory automation. They let machines share data and improve processes on their own. Predictive maintenance systems use transducers to find issues early. This saves money and increases productivity. IoT also helps motion control systems work better in factories. These systems ensure precise and smooth operations.

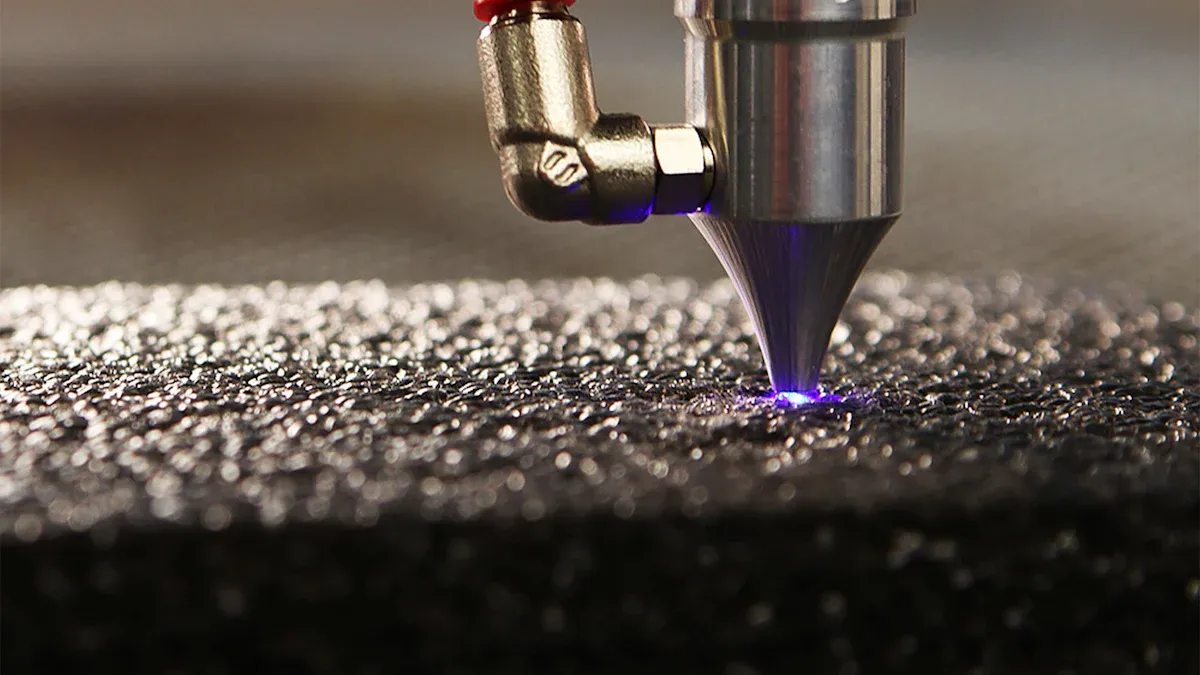

Material Innovations in Active Transducers

Advanced composites for durability and sensitivity

New materials are making transducers tougher and more sensitive. These materials help transducers survive tough conditions without losing accuracy. For example, biosensing devices now use improved transducers for better results. This is especially useful in wearables, where strength and accuracy matter most.

Eco-friendly and sustainable materials

Technology is becoming more eco-friendly, including active transducers. Makers now use green materials to lower environmental harm. These materials reduce waste and make parts easier to recycle. Using sustainable methods helps the planet while keeping technology effective.

Miniaturization of Active Transducers

Applications in wearable devices and medical implants

Smaller transducers are creating new uses in wearables and medical tools. Tiny transducers make devices lighter and easier to wear. For example, portable EEG systems now track brain activity more easily. In healthcare, small transducers are used in smart clothes and rehab cameras. Tests show these tools improve recovery and posture tracking.

Challenges in maintaining performance at smaller scales

Miniaturization has benefits but also challenges. Keeping accuracy in tiny transducers needs smart designs and better materials. Studies show sensors need careful tuning to stay precise. Even with challenges, mini transducers are growing in healthcare and gadgets.

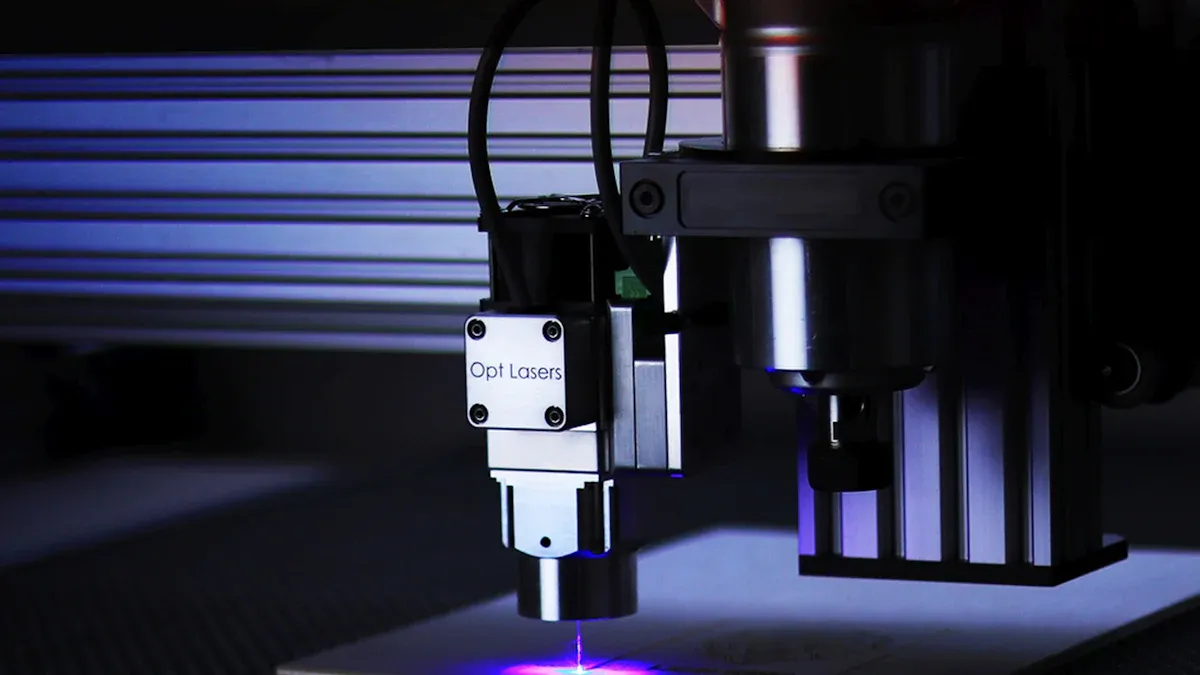

AI and Machine Learning in Active Transducers

Predictive maintenance and self-calibration

AI and machine learning are changing how active transducers work. They help find problems early, avoiding breakdowns. This reduces downtime and makes equipment last longer. Machine learning studies sensor data to spot signs of wear or damage. For example, combining data from many sensors improves prediction accuracy.

Good data is needed for these systems to work well. Methods like cleaning and organizing data make it ready for use. Explainable AI shows how predictions are made, building trust in the system. Self-calibration is another big improvement. Transducers with machine learning can adjust themselves. This removes the need for frequent manual fixes, saving time and effort.

Improved signal processing and noise reduction

Signal processing is key for transducers, especially in noisy places. AI and machine learning help by removing unwanted noise. This makes signals clearer and more accurate. Smart algorithms check data instantly, separating noise from real signals. This ensures transducers give correct readings, even in tough conditions.

Machine learning also makes signal processing faster and better. It adjusts to changes, keeping performance steady. For example, in motion control, it reduces interference to stay precise. This is vital in fields like aerospace and healthcare, where accuracy matters most. Adding AI improves performance and keeps up with new technology trends.

Tip: Focus on clean data and testing models when using AI. These steps are important for creating reliable systems.

Impact of Active Transducer Advancements on Precision and Performance

Better Measurement Accuracy

Uses in aerospace and car industries

Active transducers have improved measurement accuracy in planes and cars. In planes, LVDT transducers check landing gear length and angles. These measurements help planes operate safely and efficiently. In cars, transducers measure movements like brake pedal travel. This data is crucial for testing brakes and calculating speed, improving safety and performance.

The growing aerospace industry needs LVDT transducers for precise tasks.

Car makers use these sensors to make vehicles safer and more reliable.

Feature | Meaning |

|---|---|

Accuracy | How close the measured value is to the real value. |

Sensitivity | The smallest change the sensor can detect. |

Nonlinearity | How much the output differs from a straight line response. |

Nonrepeatability | Differences in results when measuring the same thing repeatedly. |

Calibration | Adjusting the sensor to ensure correct measurements. |

These features show how advanced transducers improve reliability in important fields like aerospace and cars.

Importance in science and lab tools

Active transducers are very useful in science and labs. They give accurate and repeatable measurements for experiments needing high precision. For example, scientists use them to measure tiny changes in force or pressure. This helps in fields like material science and medicine.

In lab tools, transducers ensure steady performance. Machines like spectrometers depend on accurate data for good results. With better transducers, labs can get more precise and reliable findings.

Higher Energy Conversion Efficiency

Role in renewable energy systems

Active transducers help renewable energy systems work better. In solar panels, they adjust photovoltaic cells for maximum sunlight capture. In wind turbines, they measure blade angles and wind speeds to improve power generation.

Recent tests show how material thickness affects efficiency:

Efficiency (%) | Efficiency Drop Factor | |

|---|---|---|

1 | 0.139 | N/A |

10 | 0.018 | 7 |

100 | 0.0056 | 25 |

These results highlight how materials can boost energy conversion rates.

Cutting energy waste in factories

In factories, active transducers reduce energy waste by improving systems. For example, they monitor machines to keep them running efficiently. This lowers waste and saves energy. Automation also benefits, as transducers allow precise control of processes.

By fixing inefficiencies, transducers help industries cut energy use and pollution while staying productive.

Growing Uses in Different Fields

Healthcare: Medical tools and devices

Healthcare uses active transducers for their accuracy and flexibility. Ultrasound transducers are used for imaging, therapy, and delivering medicine. They give detailed views of the body, helping doctors diagnose and treat patients.

Advances in ultrasound tech now allow nerve stimulation and particle control.

Wearable medical devices with transducers track vital signs, improving patient care.

Consumer Electronics: Smarter gadgets

Active transducers have made electronics smarter and more responsive. They improve user experiences in devices like smartphones. Phones use transducers to sense touch, motion, and pressure, making them easier to use.

Fitness trackers use transducers to monitor health data.

Studies show a 240% boost in real-time data speed since 2021, giving users instant feedback.

These examples show how transducers are becoming essential in healthcare and everyday gadgets.

Challenges and Opportunities in Active Transducer Technology

Sustainability in Active Transducer Manufacturing

Cutting carbon emissions during production

Factories are working to be more eco-friendly. Active transducer makers now use energy-saving methods to lower pollution. Renewable energy powers some factories, reducing harmful emissions. Better production setups also help cut waste. The sensor market is growing fast, aiming for $300.5 billion by 2029. Sustainable practices are key to meeting this demand without hurting the planet.

Recycling and reusing transducer parts

Recycling parts from transducers is very important. Many transducers use rare materials that are hard to find. Recycling keeps these materials available for future use and reduces trash. New technology makes recycling faster and better. Proper disposal of old transducers helps protect the environment and supports reuse.

Supply Chain Dynamics for Active Transducers

Solving semiconductor shortages

Semiconductor shortages are slowing down transducer production. More devices need semiconductors, making supply chains struggle. Companies like TSMC and Samsung use AI to plan better and manage stock. These tools speed up production and save money. Still, finding enough critical materials worldwide remains a challenge.

Securing rare materials for production

Rare materials are needed to make high-quality transducers. Political issues and high demand make getting these materials harder. Qualcomm uses AI to check suppliers and reduce risks. Material recovery technologies are improving, helping solve shortages. These steps ensure steady production for industries needing transducers.

Compliance with Industry Standards

Following safety and performance rules

Rules for safety and performance guide the transducer market. Transducers must meet strict standards to be approved. Companies invest in research to make better products. For example, renewable energy needs transducers with higher efficiency levels.

Keeping up with changing global rules

Global rules for transducers are always changing. Industries like healthcare and cars focus on safety, making compliance crucial. Governments fund projects in energy and infrastructure, pushing for advanced transducers. Staying updated with these rules helps companies stay competitive.

Note: The transducer market is growing quickly due to new technology and rising demand in areas like smart cities and electronics. This growth brings both challenges and chances for manufacturers.

Challenges and Opportunities | What They Mean |

|---|---|

Market Growth | The market is expanding due to better tech and energy-saving needs. |

Intense Competition | Many companies compete by offering creative products for various uses. |

Regulatory Standards | Meeting strict rules requires spending on research and development. |

Demand for Renewable Energy | Renewable energy needs advanced transducers to work efficiently. |

Smart Infrastructure | Smart city projects increase demand for building and energy systems. |

Consumer Electronics Growth | Electronics rely on transducers, driving market growth. |

Focus on Safety and Compliance | Safety rules in healthcare and cars need high-quality transducers. |

Government Initiatives | Funding for energy and infrastructure boosts demand for better tech. |

Strategies for Using Active Transducer Improvements

Spending on Research and Development

Teaming up with schools and companies

Working with universities and companies speeds up new transducer ideas. These teams mix school knowledge with business tools to make big changes.

In 1957, Medtronic and the University of Minnesota made the first implantable pacemaker. This changed medical devices forever.

These partnerships share knowledge, combine resources, and find funding. These are key for improving healthcare tools.

By teaming up, you can create smart solutions for real-world problems.

Helping new businesses grow

Funding startups working on transducers can lead to big changes. Startups bring fresh ideas and quick ways to solve problems. Supporting them with money helps you stay ahead in the market.

Governments and private groups are funding these startups more often. This support leads to new ideas and bigger solutions. By helping startups, you grow the industry and gain from new advancements.

Fully Using Active Transducer Technologies

Teaching workers about new tools

Using advanced transducers needs skilled workers. Training programs help your team learn to use and fix these systems. Classes, certifications, and practice sessions can prepare them for modern tech.

Trained workers make transducer systems work better. This lowers mistakes and boosts productivity. Spending on training is important for using new tools well.

Updating old systems to work with new tech

Adding transducers to older systems can make them better. Updates help old setups work with new tools, saving money on replacements.

For example, adding IoT-enabled transducers to old systems improves data tracking. This saves money and makes operations smoother. Updating systems connects old and new tech easily.

Customizing and Growing Transducer Solutions

Making solutions fit specific needs

Customizing transducers for certain industries improves how they work. Special designs solve unique problems and work better.

XMPro creates custom solutions for different industries. These help solve specific challenges.

Customization improves operations and matches tech with business goals.

Focusing on custom solutions gives better results and meets industry needs.

Growing production to meet demand

Scalable transducers help handle growing market needs. While they cost more at first, they save money later by cutting future costs.

Scalable AI systems lower costs over time.

Scalable designs allow growth without losing performance.

Planning for scalability early saves money and keeps systems flexible for the future.

Tip: Think about scalable designs from the start. This saves money and prepares for future growth.

Active transducers have changed how industries achieve accuracy and performance. New improvements, like IoT connections, better materials, and AI-based adjustments, make them more powerful. For example:

Magnetic flux gate sensors are as accurate as old transformers. They also work better than Hall sensors for direct current checks.

These sensors are fast, precise, and stable, as shown by Wang et al. (2022).

In healthcare, wearable devices with transducers give detailed body data. They measure things like heart rate (75.2 bpm) and joint angles (120.5°). Machine learning makes these devices smarter, offering custom solutions to help people recover better.

Industries need to use these new tools to stay ahead. By using active transducers, businesses can improve efficiency, save resources, and get better results. The future will reward those who keep innovating.

FAQ

What is an active transducer?

An active transducer changes physical signals, like heat or pressure, into electrical signals. It works without needing extra power and uses energy from the input.

How are active transducers different from passive ones?

Active transducers make their own electrical output. Passive transducers need outside power to work. Active ones are smaller and work more efficiently.

Where are active transducers used?

They are used in fields like healthcare, cars, and airplanes. Examples include medical implants, motion trackers, and green energy systems.

Why is IoT important for active transducers?

IoT helps share and check data instantly. This makes systems faster, predicts problems early, and improves automation in factories and smart homes.

What problems come with making active transducers smaller?

Smaller transducers can lose accuracy. To keep them working well, they need better materials and careful designs.

How does AI help active transducers?

AI makes signals clearer, finds problems early, and helps devices adjust themselves. This improves accuracy and reduces the need for fixing by hand.

Are active transducers good for the environment?

Yes, many are made with eco-friendly materials. Recycling their parts also cuts waste and saves rare resources.

How can industries use better active transducers?

Industries can spend on research, train workers, and update old systems. Custom designs and making more transducers help meet growing needs.

Tip: Pick transducers that match your needs for the best results.

See Also

Exploring What Defines an Active Transducer in Detail

The Importance of Force Sensitive Resistors in Technology

Calculating Loading Errors in Potentiometers Made Simple